Molygraph’s SmoothKut SS 5200 is a breakthrough in metalworking fluids

By Staff Report March 7, 2025 6:46 pm IST

A leading auto component manufacturer faced coolant-related issues, causing rust, high costs, and inefficiencies. Switching to Molygraph Smoothkut SS 5200 Premium improved sump life, stability, and machining quality while reducing costs by 20-22%. This case highlights the impact of superior lubrication solutions.

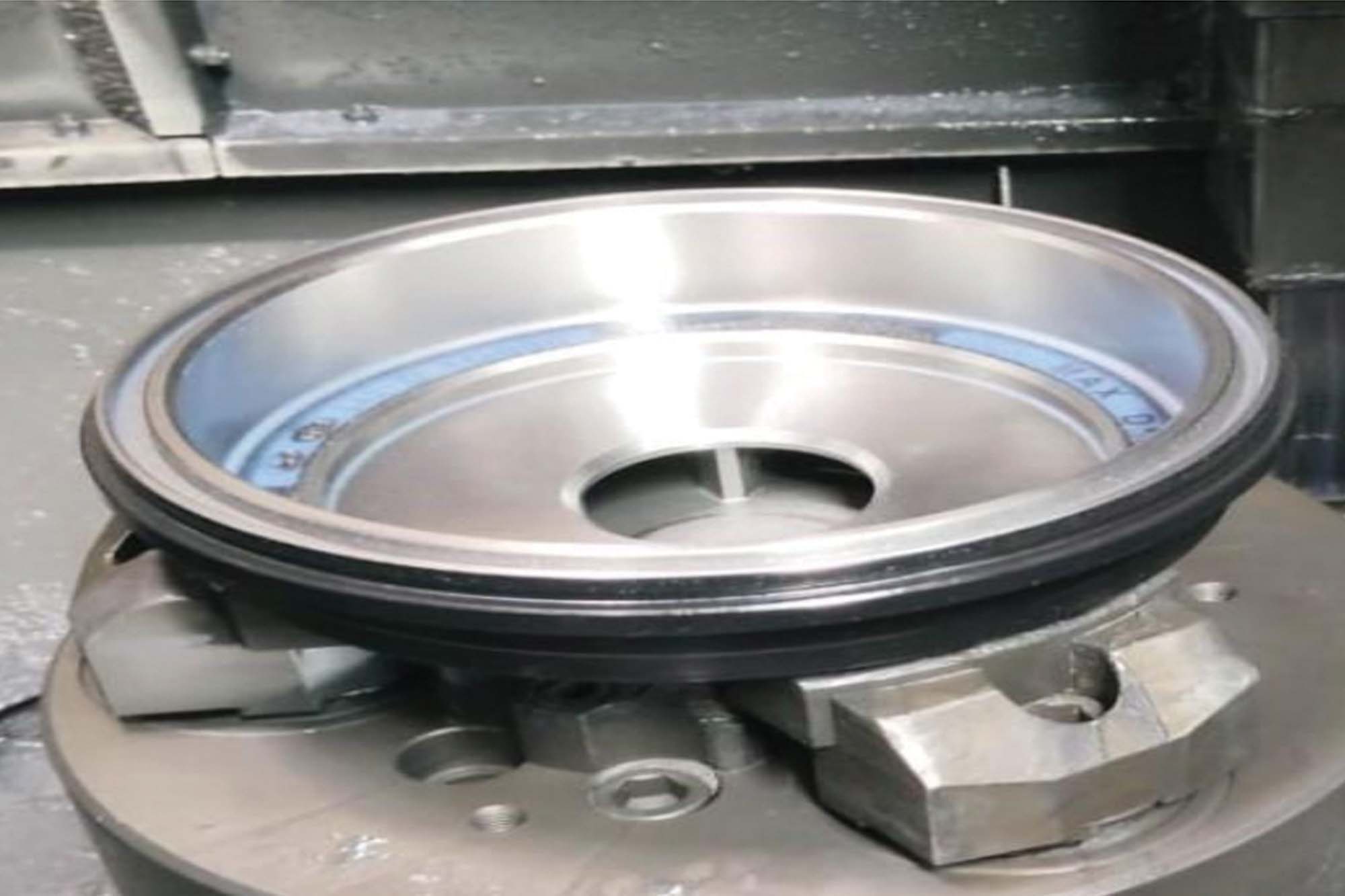

Automotive manufacturing requires optimised production efficiency and cost-effectiveness. A leading auto component manufacturer specialising in grey iron disc brakes for OEMs faced a significant challenge with their machining process. Frequent coolant-related issues were causing increased costs, rust formation, and production inefficiencies. This case study explores how a switch to Molygraph Smoothkut SS 5200 Premium transformed their operations, leading to substantial cost savings and improved performance.

The challenge: Rising costs and operational setbacks

• Rust formation – Rust was observed on machined parts despite applying coolant, leading to quality concerns.

• Frequent coolant concentration & pH drops – The coolant required constant monitoring and frequent adjustments to maintain efficiency.

• Short sump life – The coolant had a lifespan of only about a month, necessitating frequent replacements.

• Bacterial contamination – The formation of bacteria inside the coolant tank led to hygiene and odour issues.

• Tramp oil accumulation – Excessive tramp oil accumulation caused a foul smell and further compromised coolant performance.

• Rising costs – Direct and indirect costs increased due to high coolant consumption and maintenance efforts.Expectations: The need for a reliable solution

The manufacturer required a coolant that could –

- Extend sump life

- Maintain stable concentration and pH levels

- Prevent rust formation

- Eliminate bacterial contamination

- Effectively reject tramp oil and reduce sludge formation.

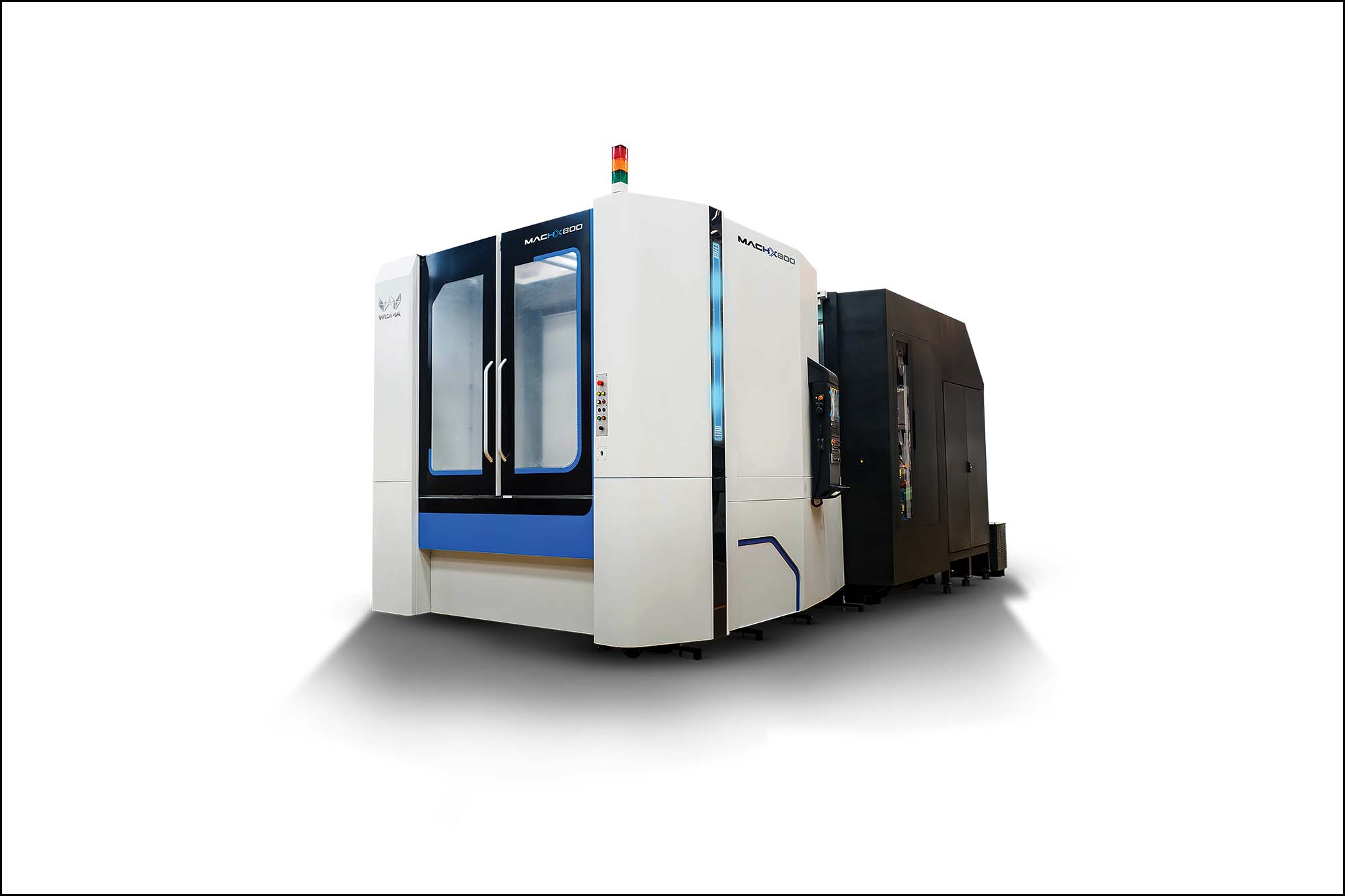

The solution: Molygraph Smoothkut SS 5200 Premium

After careful evaluation, Molygraph Smoothkut SS 5200 Premium was introduced into the machining process. This high-performance coolant provided multiple benefits –

- Excellent emulsion & bio-stability – Ensured optimal performance even in hard water conditions.

- Superior tramp oil rejection – Prevented oil accumulation and foul odours.

- Rust & bacteria prevention – Enhanced metal protection, eliminating rust formation and bacterial growth.

- No sludge or scum formation – Maintained a clean coolant system, reducing maintenance efforts.

- Improved surface finish – Enhanced machining quality and efficiency.

The outcome: Measurable performance gains

Following the implementation of Molygraph Smoothkut SS 5200 Premium, the manufacturer experienced significant improvements – Extended sump life, stable concentration & pH levels, elimination of rust & bacteria, reduced coolant consumption, operator satisfaction, and cost savings (20-22% bi-monthly cost reduction) were achieved.

This case study underscores the importance of choosing the right lubrication and coolant solutions to optimise industrial operations.

———————————————————————————————–

Molygraph’s expertise in speciality lubricants continues to drive efficiency and innovation across industries. For more details on our products and offerings, contact us at +91 8104409925 or email at sales@molygraph.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.