From users for users

By Staff Report September 16, 2024 7:07 pm IST

In a ZEISS pilot project hosted by Starrag, the new-generation ZEISS PRISMO 7/12/7 fortis with the highperformance package ZEISS CMM Acceleration Mode for Aerospace Applications combines accuracy and productivity in breathtaking style. Benefits include a remarkable 80% reduction in the rotary table axis definition time and superlative interaction with ZEISS CALYPSO software.

“Speed and accuracy were always a contradiction for us before we installed the new generation of ZEISS PRISMO fortis,” Roland Ziltener, Head of Quality Management, Starrag Group.

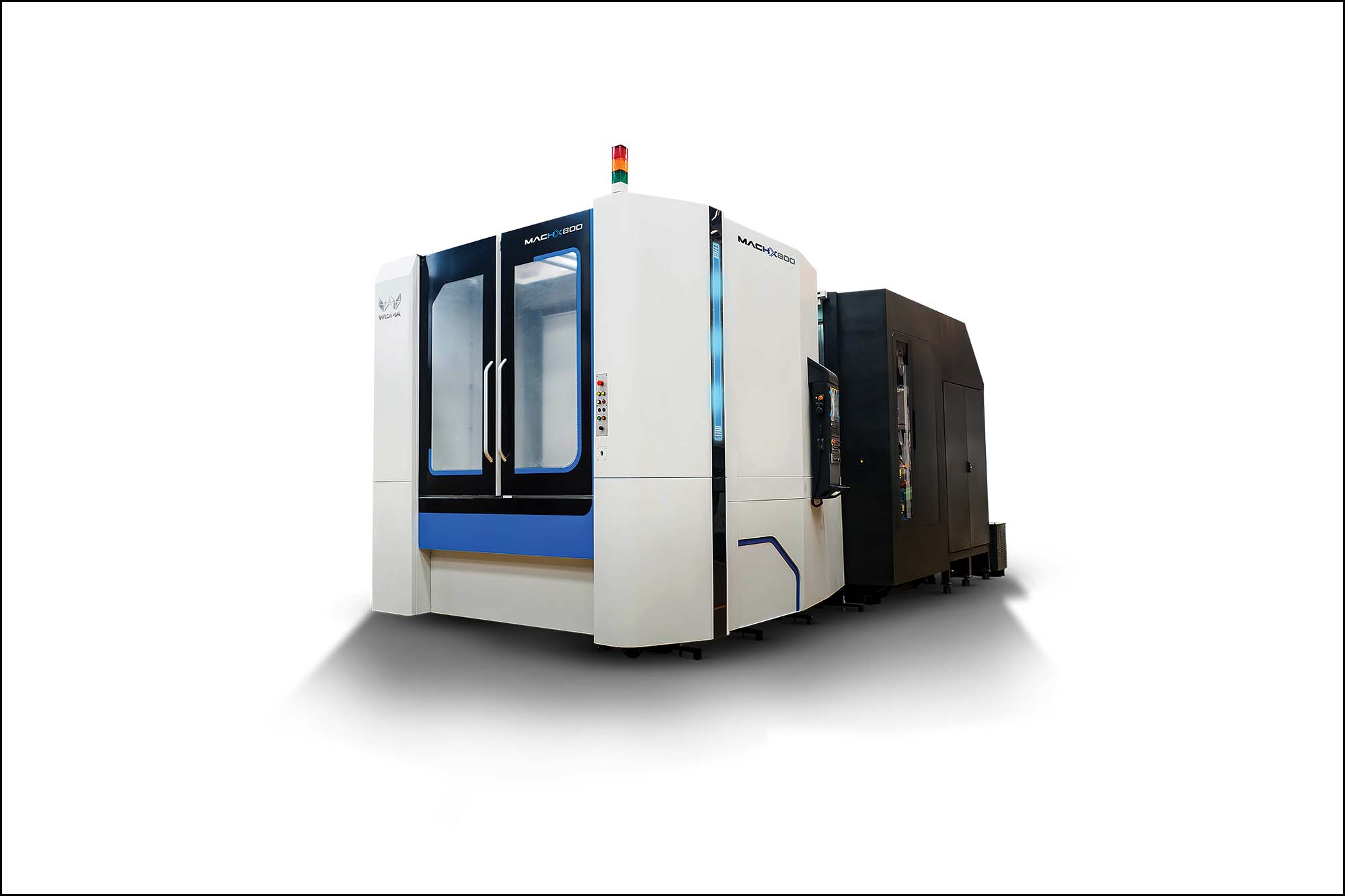

Headquartered in Rorschacherberg, Switzerland, the Starrag Group manufactures machining centres for production solutions that handle turbine blades, blisks, and more, focused on aerospace applications. Precision powers the aerospace industry, and accuracy requirements have grown far stricter in recent years. To serve the expanding and varying demands of customers, Starrag must perform high-efficiency measurements that deliver fast, highly accurate, and easily reproducible results.

The pilot project featured the deployment of the new-generation ZEISS PRISMO 7/12/7 fortis in a prominent role within the quality lab, and Starrag was impressed by the outcomes. Starrag’s Head of Quality Management, Roland Ziltener, sums it up neatly: “In the field of measuring technology, accuracy is usually slow. But with ZEISS PRISMO 7/12/7 Fortis equipped with ZEISS CMM Acceleration Mode for Aerospace Applications, the case is the opposite.

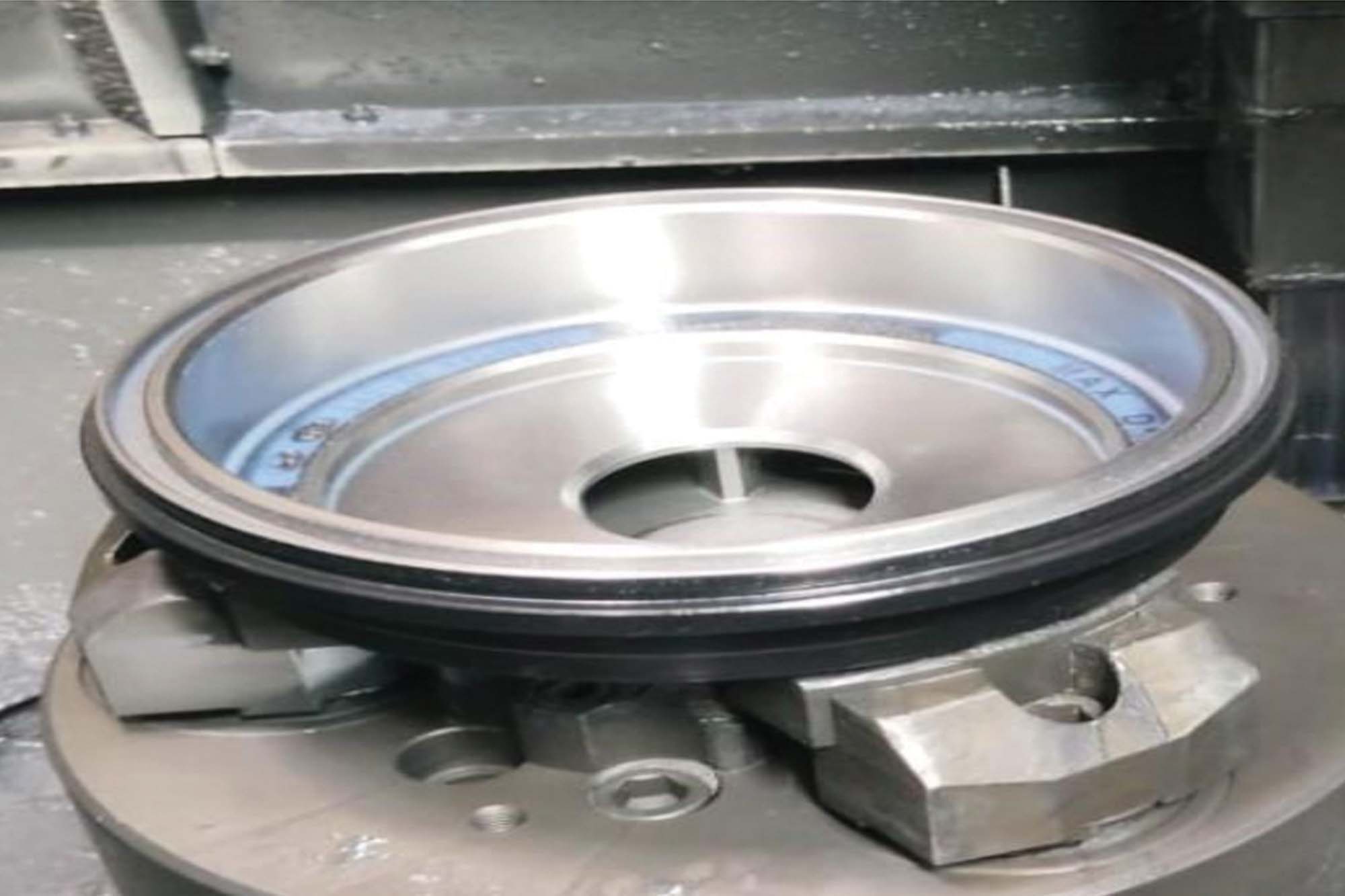

A fresh approach to rotary table applications

The new-generation ZEISS PRISMO 7/12/7 fortis is a rotary table for sharply reducing measuring times. The ZEISS Acceleration Mode for Aerospace Applications package combines a pair of rotary table measurement options: ZEISSVAST Rotary Table (ZVR) and ZEISS VAST Rotary Table Axis (ZVRA). These promote a fresh approach to rotary table applications by boosting the rotary table positioning speed and axis definition speed. Indeed, ZVRA cuts the axis definition period from 60 to 12 seconds – a remarkable 80% time saving on a process performed for each workpiece at Starrag. The faster positioning speed also ensures fewer styles are needed, making measurement more flexible. ZEISS and Starrag exchanged geometry data and worked together to identify effective contour-checking solutions better at handling difficult geometries. ZEISS has also made significant efforts to provide Starrag training and support in real-world environments.

The implementation of this new solution on-site went smoothly, with Starrag also drawing on its years of experience using ZEISS CALYPSO software. This ensured easy programming of contours. Ziltener reports that it was not difficult for his team to get to grips with the latest software version and the various upgrades featured in the new ZEISS PRISMO 7/12/7 fortis. Moving beyond good/ bad analysis of parts, Starrag relies on high-quality feedback to determine machine performance: ZEISS CALYPSO responds to these requirements by delivering highly accurate and repeatable results while providing the data and graphics that support further development. Promoting the interpretation of results also aids Starrag’s interaction with suppliers by offering a basis for discussing deviations and solutions.Measurement is now 74% faster with sufficient accuracy

Chief among the many benefits of the pilot project is the remarkable increase in productivity. With Starrag, you can measure more parts in less time with the same accuracy. The indication of this productivity boost is the 74% reduction in the time required to perform the standard turbine blade measurement program by Starrag. While the program once took 4 minutes 30 seconds and was focused on repeatability, it now takes 70 seconds to return accurate and reproducible results. This gives the company greater flexibility in terms of what to measure and which workpieces – and the large number of turbine blades and cuts awaiting measurement means the benefit is multiplied. Ziltener states that, in combining the two seemingly contradictory advantages of sufficient accuracy and stunning speed, the new-generation ZEISS PRISMO 7/12/7 fortis “never fails to amaze” end customers on site.

The new ZEISS PowerSaver feature also “makes a massive contribution to energy saving” and sustainability at Starrag, a benefit of the ongoing energy crisis. Easy to use and only needing to be programmed once, ZEISS PowerSaver cuts consumption to zero during user-defined downtime periods and runs seamlessly in the background. Occupational safety is a point of emphasis at Starrag , and the new laser-based system for automatically reducing speeds in the event of a hazard and subsequently increasing them offers the ideal combination of safety and performance. This enables safe loading and operation, does not distract the user, and is pleasant to work with. Finally, numerous ergonomic upgrades, such as a slimmed-down control panel with a dedicated holder, improve workpiece handling and the overall accessibility of the new generation of the ZEISS PRISMO Family.

ZEISS PRISMO 7/12/7 Fortis and ZEISS CMM Acceleration Mode for Aerospace Applications set up Starrag for continued long-term success in quality assurance. The company’s focus is beyond collecting results for a given workpiece – as Ziltener says, “we must be able to interpret the results and data” and “discuss these with our internal and external partners.” This pilot project solution helps them to do just that, as ZEISS CALYPSO software promotes the easy documentation and visualisation of results even by non-experts. The multi-layered approach implemented by ZEISS CALYPSO makes these features accessible while providing more in-depth options for those with expertise. In short, this pilot project has already helped Starrag take its quality assurance to new heights and their reciprocal partnership with ZEISS offers plenty of potential for the future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.