Fast and effective but also gentle

By Staff Report December 7, 2024 6:59 pm IST

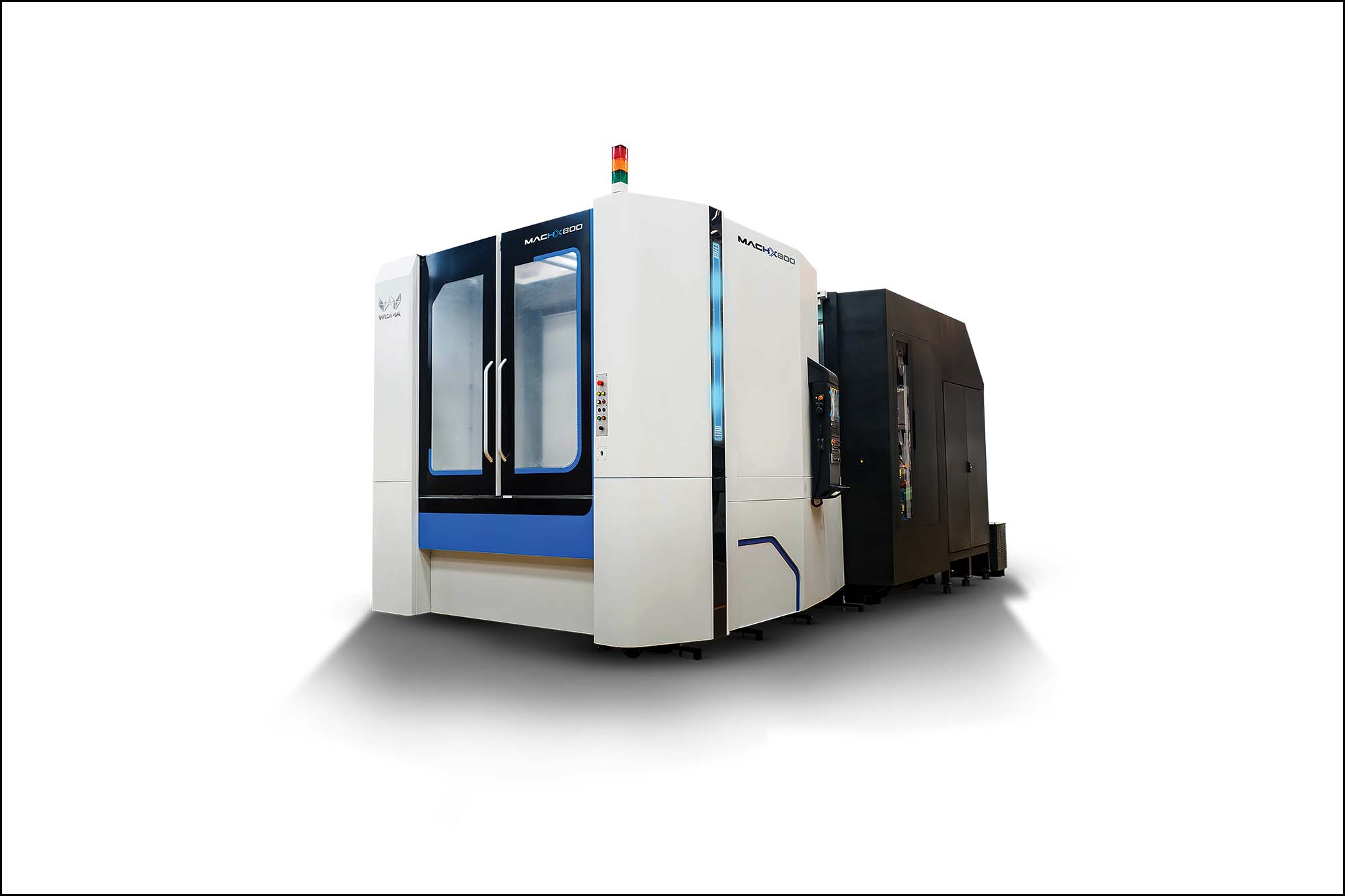

Alupress GmbH, which has Rösler’s custom-engineered solution, used new comprehensive shot blast solutions for electric vehicle components. The machine’s advanced design makes it efficient and can automate the de-flashing of lightweight aluminium components for electric vehicles.

Due to the rapidly growing demand for components for electric vehicles, Alupress GmbH, a renowned manufacturer of innovative aluminium and magnesium die-castings, had to increase its shot blasting capacity. For this purpose, the company purchased a continuous feed spinner hanger blast machine, including a power and free transport system, from Rösler. The custom-engineered equipment design guarantees effective and gentle de-flashing of the workpieces without the risk of warping.

Aluminum has a relatively low bulk density, which allows significant weight savings in components for electric vehicles, resulting in an expanded battery operating range. Therefore, the number of components produced from this light metal, made by die-casting and other production methods, is rapidly growing. Another goal for components for EVs is to create complex but thin-walled designs, which allow additional weight savings. This also applies to the housings for different control devices manufactured by Alupress GmbH in Hildburghausen, Germany. At the Italian subsidiary of Alupress AG in Brixen, the growing automotive industry demand required investment into a new shot blast machine specially adapted to the strict customer requirements.

An automated all-around solution minimises the risk of workpiece warping.

The shape and wall thickness of the aluminium and magnesium die-castings demanded a shot blast process that treats the components gently without warping them. At the same time, the shot blast operation had to be quick and run fully automatically. After the shot blast process, the components pass through a cleaning device and undergo a quality control check before they are packed and shipped. Therefore, besides the shot blast machine, the project scope also included a transport system that conveys the components automatically through the de-flashing and cleaning stations. Alupress chose Rösler as a partner for this important project because of the convincing quality and productivity of the equipment. They also considered the after-sales service aspect. Rösler had also proven its technical competence in processing delicate workpieces in another, similar project. Moreover, for many years Alupress has been using shot blast machinery from Rösler and, therefore, knows this equipment’s quality, productivity and reliability.

Equal application of force prevents the warping of the workpieces.

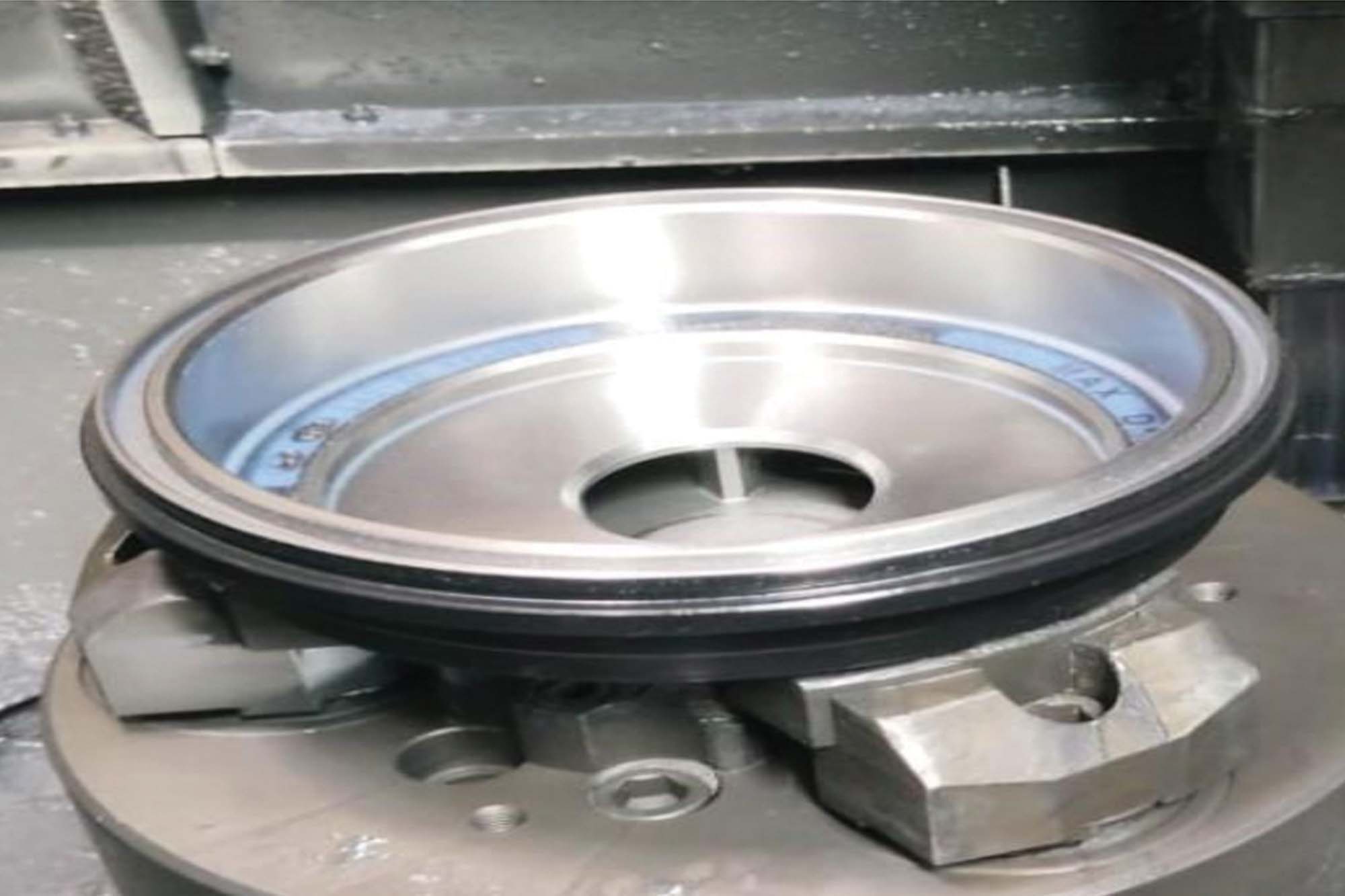

The continuous feed spinner hanger shot blast machine, model RHBD 13/18-So has eight special turbines, each with an installed power of 11 kW. They are for gentle, fast and effective de-flashing in continuous flow. The turbines contain extra wide throwing blades generating a broad blast pattern. Furthermore, contrary to the standard placement of the turbines on one side of the blast chamber, the turbines were placed on both sides. This duplex turbine placement with the broad blast pattern, generates a gentle blast operation. This blast reduces the risk of warping. But the comparatively high blast media throughput, needed for efficient de-flashing and cleaning of the light metal components, ensures a fast and effective shot blasting operation.

Another feature for preventing workpiece warping is that the carrier, holding 60 to 80 components, rotates during the entire shot blast process while oscillating back and forth in three positions. This guarantees that flashes and burs are safely removed, even in difficult-to-reach areas like undercuts. To prevent the small aluminium cut wire from being sucked out of the shot blast machine by the exhaust airflow and to maintain the ideal operating mix, the dust collector and the cascade air wash separator were upgraded with technical modifications. Of course, the wet dust collector fully complies with ATEX requirements.

Necessary maintenance work is facilitated by multiple connections for cleaning equipment at different sections of the shot blast machine.

Ergonomic features for improved employee health

A power and free handling system makes the transportnation of the workpieces easy and trouble-free. At the load/unload station, the height of the workpiece carrier can be adjusted to the height of the respective operator, thus allowing ergonomic and comfortable working conditions. Moreover, generously laid-out buffer sections in the transport system permit continuous operation, even during breaks and rest periods. All hazardous areas around the shot blast machine are equipped with safety mats instead of the usual sensors and enclosures for the absolute safety of the personnel.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.