GE Aerospace to invest in its manufacturing facility at Pune

By OEM Update Editorial April 10, 2024 3:59 pm IST

The facility manufactures components for commercial aircraft engines, which are shipped to GE Aerospace’s global factories for production. Since its inception, the facility has played a critical role in the development of local aerospace manufacturing capabilities.

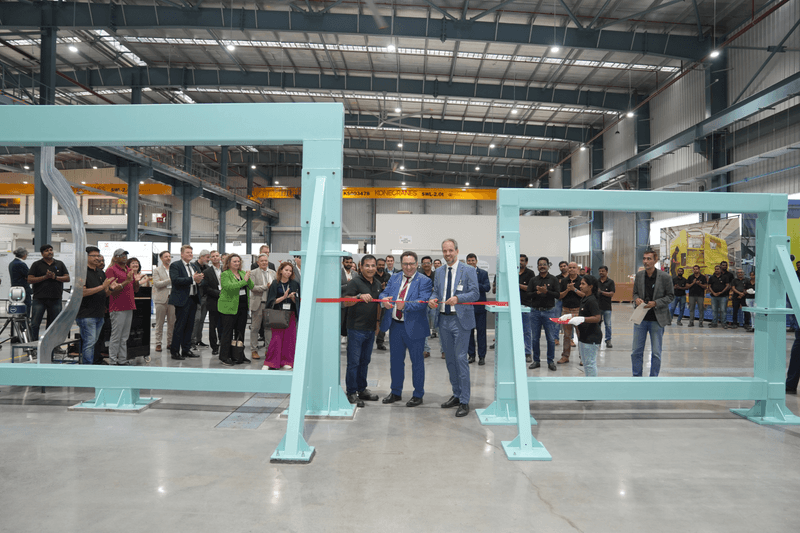

GE Aerospace disclosed an investment of over 240₹ crore (~USD 30 million) to expand and enhance its manufacturing facilities in Pune, after its recent listing on the New York Stock Exchange.

The investment will allow the facility to introduce new projects and manufacturing processes by acquiring machines, equipment, and specialized tools, as well as increasing capacity for existing items.

“Our team at our Multi-modal Manufacturing facility at Pune has a strong focus on safety, quality and delivering for our customers. I am delighted to see the expansion at this site which has already become a strong contributor to our global supply chain of aircraft engine components,” said Mike Kauffman, vice president, Global Supply Chain at GE Aerospace.

“This investment helps us to continue our growth in aerospace in India, giving us the resources, we need to meet increasing customers’ demand,” said Amol Nagar the managing director for GE Aerospace’s Pune facility.The factory that manufactures components for commercial aircraft engines. These are shipped to GE Aerospace’s global factories, where they are used to produce the G90, GEnx, GE 9X, the world’s most powerful commercial jet engine, and CFM’s LEAP engines, a GE-Safran joint venture. Since its inception, the facility has played a critical role in the development of local aerospace manufacturing skills, educating roughly 5000 employees in specialized precision manufacturing methods.

The plant is ISO14001 and ISO45001 certified, and it has implemented environmental best practices and stewardship in the community. For example, renewable energy accounts for 30 percent of its electricity usage, there is no liquid discharge, 1 crore litres of water (100 million gallons) are recycled and reused each year, and 20 metric tonnes of plastic are recycled.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.