Role of Industrial IoT for OEM machine manufacturers

By OEM Update Editorial August 23, 2022 11:39 am IST

Renata IoT: Supporting the OEM machine manufacturers and measurement instrumentation industry through Industrial IoT.

F or OEM machine manufacturers OEM machine manufacturers

can significantly benefit from integrating IIoT(Industrial IoT) in their machines. On the business side, it helps them differentiate in the market through agile after-sales services and increase revenues. It helps them save on cost and response time, building a more robust business and long-term reliable relationships with their customers. On the operations side, it helps them monitor their machines once they are delivered to the customers, maintain historical data, troubleshoot, monitor correct machine usage, root cause analysis, segregate defect trends and maintenance issues, maintain digital documentation for easy access, timely reporting and also complete remote control for machine setting changes and operations management. Such a capability is a boon for any machine manufacturer who wants to make their business and operations much more efficient and take them to the next level of automation.

The machines that can use such a capability include any Special Purpose Machines, Compressors, Boilers, Pumps, Cranes, Lifts, Transformers, UPS, or Diesel Generators. The list is endless. Any standalone machine critical for the end customer will benefit hugely from such an industrial IoT solution. One such customer of ours is a compressor manufacturer. Earlier, when they used to send the compressors to any remote end-customer site, they would have to send a person physically in case of any operational issue. This used to take a lot of time and cost. End customers would also have to wait a long time to get support. But now, we have completed integrating the compressor controller through our web Scada IIoT solution and not only replicated the compressor HMI for web access but also greatly enhanced its capability through historical data storage, digital documentation, single-click reporting, cross-machine alarms in a single dashboard on top of crucial machine parameter monitoring and complete remote control. This has given a centralised monitoring and control facility to the service engineers spread across India and the management of the machine vendor and the end customer. We will now provide a complete analytics engine on top of the remote monitoring and control layer. The idea is to support the customer through operational insights, trends, automated root cause analysis, and real-time condition monitoring alerts.

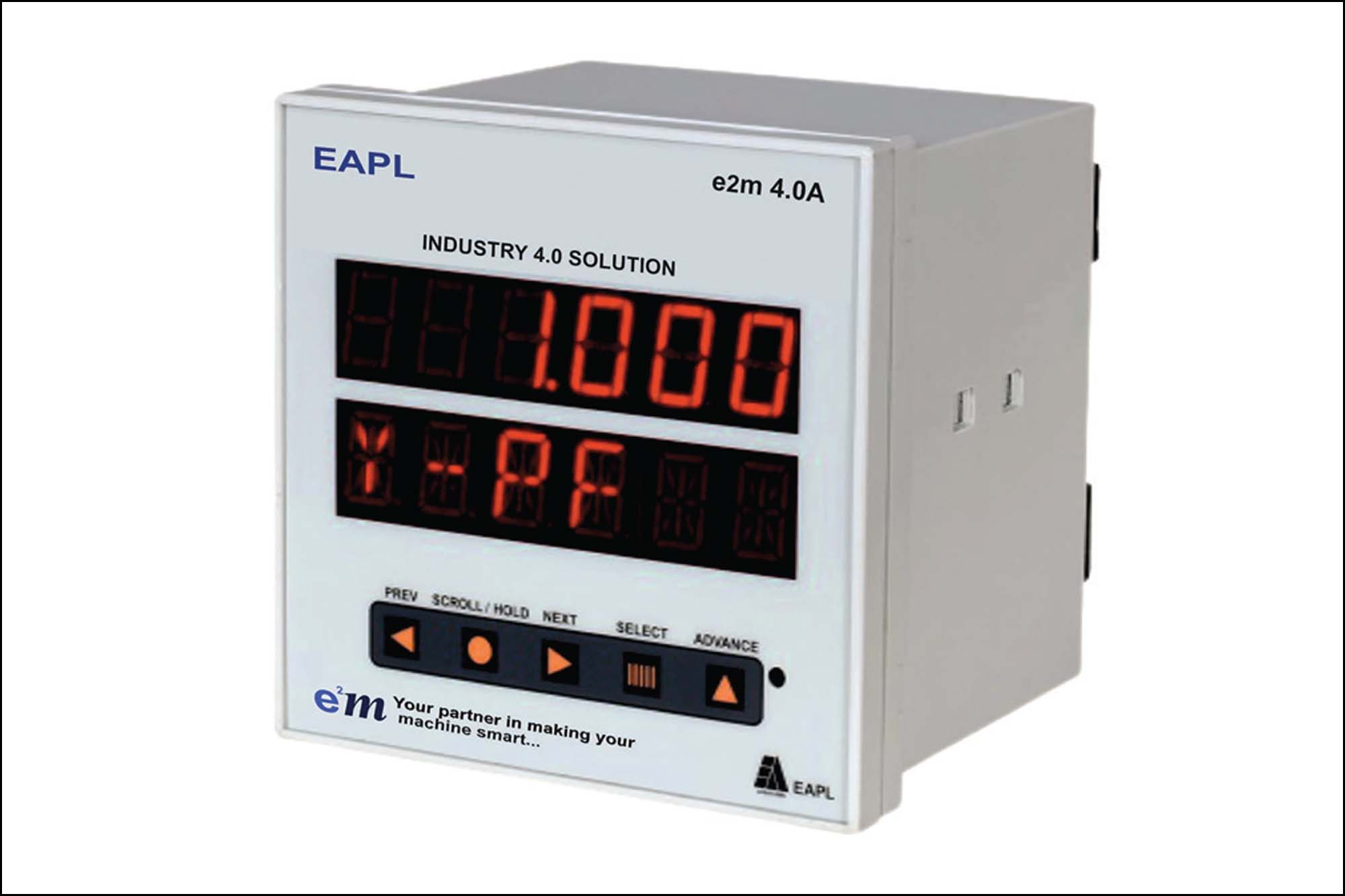

For the Measurement instrumentation industry

Measuring instruments benefit significantly from the use of Industrial IoT solutions. They are generally used for measuring parameters like vibration, noise, flow, dimensions, spatial parameters like thickness, tilt, proximity etc., displacement through ultrasonic, capacitive, resistive, laser sensors, and mechanical measurements like mass, weight, force torque, density, velocity, thermal, temperature, radiation etc. All these instruments measure readings and are either able to log data locally or can be connected to a PC for data transfer. Such a mechanism is cumbersome, time-consuming and error-prone as it is human-dependent. Moreover, their complementary PC software is not capable enough for a diverse set of analyses. We have recently provided a related IIoT solution to a Japanese instrumentation company. They are now using an IIoT solution to offer their end-customers remote monitoring and analytics capability. Today, their customers are asking for such a solution. Why not be proactive and add such a capability to create a differentiated product portfolio for yourself as an instrumentation company? This will help with real-time monitoring and historical analytics and improve products through trend analysis. Using AI (artificial intelligence) would also allow you to make business and operational excellence-led improvements, leading to lower costs and higher revenues.

Renata Envirocom Pvt. Ltd.

https://renataiot.com https://www.linkedin.com/company/renataiot/

Email: anil.sagar@renataiot.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.