Making smart factories for Industry 4.0

By OEM Update Editorial August 3, 2021 5:48 pm IST

Manufacturing, as we know it, is transforming. The entire process – from design to delivery – is now consuming much less time and energy, courtesy artificial intelligence and machine learning (AI/ML).

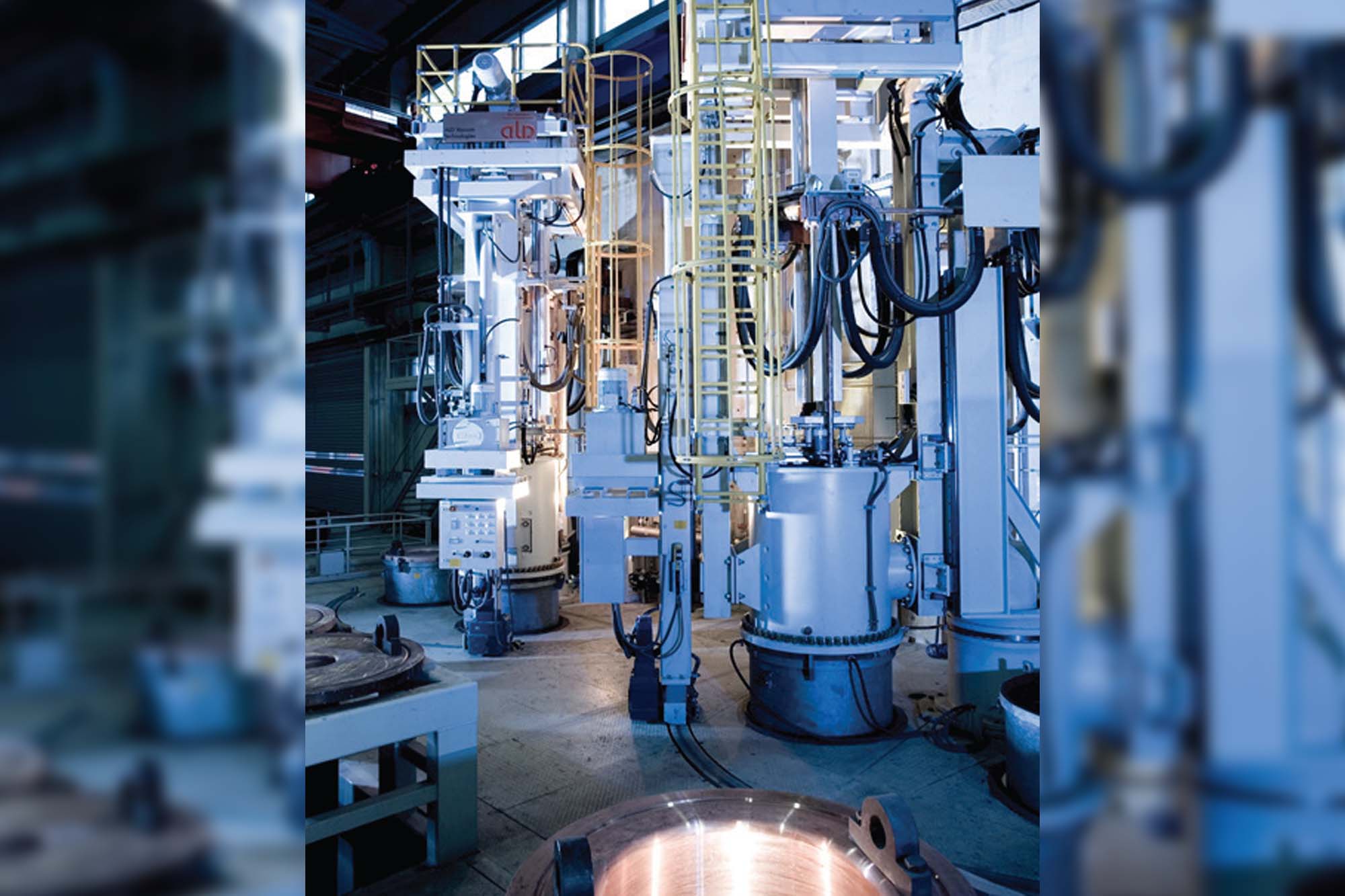

Today’s new generation of sophisticated high-performing machineries are not only environment-friendly but also cost-efficient – unravelling a true revolution. Prior to the COVID-19 pandemic, the benefits of Industrial Internet of Things (IIoT) were recognised but not fully realised. However, a year of lockdowns and travel restrictions have brought home the reality of digitalisation – no longer a choice, it has emerged as an indispensable requirement. Today, AI/ML is encouraging innovation in techniques and logistics – consequently demanding smart solutions in integral processes like lubrication servicing to drive the change.

Motivated to aid performance in this new era, industry leaders like ExxonMobil are forerunning innovation by integrating cutting-edge lubrication technologies and services into mainstream manufacturing.

Towards industry 4.0

Industry 4.0 and its smart factories mark the next phase of revolutionising operations. With changing industries, the reimagining and redesigning of work processes is now imminent. Smart technologies and automation solutions will be the new order in a connected industry system marked by the emergence of cyber-physical interfaces, IIoT, AI/ML and cloud computing.

Complete integration and exchange of information in real time are the hallmarks of Industry 4.0. A connected enterprise enhances decision-making, strengthens security and improves productivity – along with providing the complementary benefits of overall collaboration and access to the right information at the right time.

IIoT offers a chance to redefine sectors and accelerate economic growth. However, to seize these opportunities, businesses and governments must innovate and escalate investments. As the Indian economy restarts progress towards becoming a preferred manufacturing destination, current practices must make way for largescale IIoT adoption mechanisms.

Digitising oil analysis

The Mobil advantagesServing in an era of digital uptick, Mobil has been assisting customers with its Mobil ServSM Lubricant Analysis (MSLA) programme. A mobile-enabled used-oil analysis platform, it is designed to enhance efficiency and simplify processes, thereby, augmenting performance. MSLA aligns itself strongly with manufacturers’ journey towards Industry 4.0.

The platform streamlines the entire oil analysis process – from initial sample gathering to final reporting – with a Coded scan-and-go sampling bottles that deliver used-oil samples to Mobil’s oil analysis laboratory. Customers can also leverage application-specific analysis options to access results and perform customised equipment recommendations directly on their hand-held devices – saving unnecessary downtime that could affect production output and delivery deadlines.

With the MSLA program, operators can anticipate increased productivity and performance of equipment. The analysis also helps identify issues that can be mitigated with minimal downtime – thereby, reducing the amount of lubricant needed and extending overall machine life.

Mobil prioritises customer convenience and has formulated an extensive range of leading technical services that optimise maintenance programs, enhance equipment performance and ensure safety. While the industrial revolution is gradually realised, key technological advances like MSLA are aiding companies in their progress towards building and operating smart factories.

(ExxonMobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Esso and Mobil. For convenience and simplicity, those terms and references to “corporation”, “company”, “ExxonMobil”, “EM”, and other similar terms are used for convenience and may refer to one or more specific affiliates or affiliate groups.)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.