BDCC: The answer to challenges in the pressure die-casting industry

By OEM Update Editorial July 16, 2024 6:54 pm IST

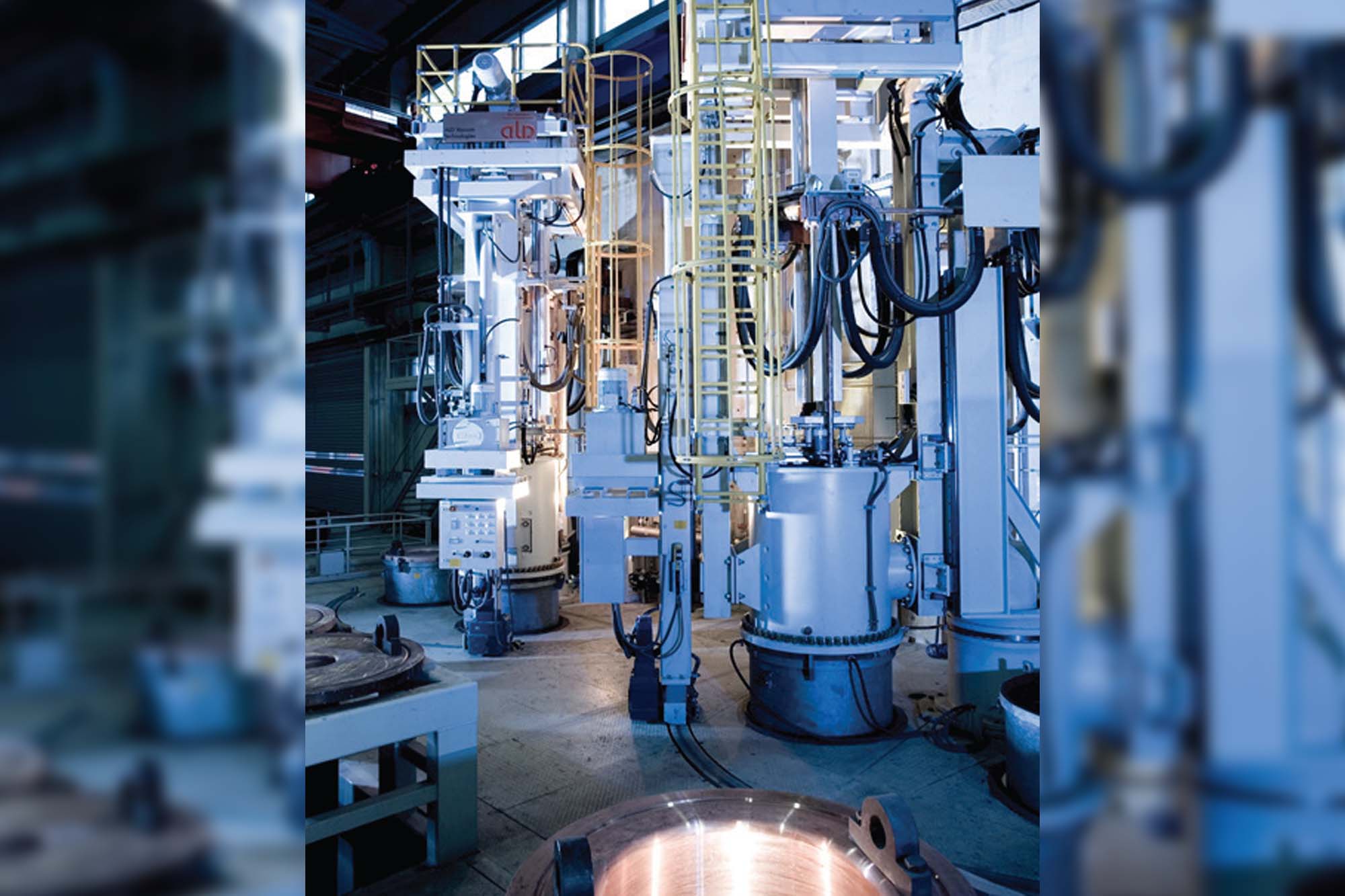

For years, the automotive industry has faced pressure to reduce vehicle weight. Lighter-weight vehicles result in lower fuel consumption and reduced CO2 emissions. One field that can contribute to achieving these weight reductions is the pressure die-casting industry. This process allows for the production of increasingly complex components and larger items, such as structural components.

The focus in the high-pressure die-casting industry is on precision, reproducibility, efficiency, low piece cost, and high volume. BÖHLER has developed a conceptual approach for its customers to address the increasing requirements of this field. It is known as the BÖHLER Die Casting Concept (BDCC).

BÖHLER Die Casting Concept

This concept is about advising and supporting customers during the starting phase of their projects and providing detailed, project-related solutions—not one-size-fits-all. By analysing a wide range of influencing factors, it is possible to find the Right hot work tool steel and the Right hardness for the casting die, the inserts, the sliders, and the cores. Among these parameters, for instance, is the pressure die-casting machine, characterised by its clamping force, forming pressure, filling factor, and casting weight. Other factors include the cooling and temperature-control system, temperature management of the die (e.g., surface and background temperature), spraying technology, and the aluminium component itself.

Based on this information, our professional sales experts work closely with the customer to select the Right material from our specific range, providing support from the product idea through component production.

Solutions for high-efficiency, high-quality production

BDCC is about complete solutions, not just material recommendations. It includes advice on the Right high-quality heat treatment, any potential coatings (e.g., for core pins), or inserts produced by additive methods, generally known as 3D printing. These are made of our proprietary powder (AMPO). This package of expertise ensures high efficiency and high-quality production for our customers.BÖHLER offers various hot work tool steels for use in high-pressure die-casting. The materials BÖHLER W300 ISOBLOC (1.2343) and BÖHLER W302 ISOBLOC (1.2344) conform to the ‘Common standards and the NADCA’.

In addition, we offer proprietary materials that are developed specially to meet higher requirements. One of these is W350 ISOBLOC, created especially for large moulds. Others are the vacuum-remelted materials BÖHLER W400 VMR and BÖHLER W403 VMR, which have optimised properties, such as a very high heat checking resistance, due to their ultra-high cleanliness levels. NADCA also includes these three materials in its listings. The product range is rounded out by BÖHLER W360 ISOBLOC, which is outstanding for use in small inserts and cores exposed to high temperatures, as this material can achieve up to 57 HRC.

With the BDCC, BÖHLER can provide a customised solution for your high-pressure die-casting mould so that you can meet tool life requirements as well.

Contributed by- voestalpine BÖHLER Edelstahl GmbH & Co KG

http://www.voestalpine.com/bohler-edelstahl

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.