Automation: The prevalent trend in cutting and welding industry

By OEM Update Editorial January 9, 2020 3:18 pm IST

Apt adoption and application of automation in the welding sector can boost the overall efficiency and growth of the sector. Automation paves the way for the industry to boost product performance and deliver uncompromised quality results to the consumers. Implementing advanced welding processes can further improvise on the delivered quality for greater productivity and welding quality in minimum investment.

In a recent announcement, the government announced allotting of Rs. 100 crores for the welding sector. Today, a lot of sectors like power, defence, and railways are being opened to the private sector and public enterprises. This opening will give rise to a large amount of manufacturing activity. The Infrastructure and Transportation Ministry is planning to use the large coastal area of the country for ease of transportation. It plans to develop more ports — big as well as small — for shipping requirements. This is all basically the new vision of the country and if we are to reach $5-trillion economy by 2025, these investments are mandatory. Because our Prime Minister’s vision is that India will be a $5-trillion economy by 2025, we hardly have 5 years to go. We are now a $1-trillion economy; we have to increase fivefold.

Rakesh Pachpor, Proprietor, Root Machinery LLP says, “With today’s innovations, I think, human intervention should be equally critical to address the safety aspect. Welding and cutting industry incurs critical applications that take place within a short period of time with intense protection.” Automation will facilitate in creating and maintaining the records of the production and achievements of the industry, whilst insisting on quality with minimum risk.

Aniruddha R. Vilekar, Head – Operations & Marketing, Ador Welding Limited, says, “Advanced welding processes can deal with issue like deformation, spatter, travel speeds and other factors, which can minimise rework, increase production and offer a competitive advantage. With the ‘Make in India’ initiative, the thrust in achieving world-class standards along with Industry 4.0 revolution in automated welding and cutting becomes more crucial as our answer to these challenges.”

R Srinivasan, Chairman, Indian Institute of Welding Technology, says that automation is very important. “Today, there is a wrong notion that automation is going to cost or reduce the use of manpower. However, that is not the case. Automation is needed in India to meet the market challenges and keep quality consistency. The manual work a welder does can use automation or can be programmed; when it is programmed automation, the repeatability of the task is promptly achieved; thus, the success rate is high. At the same time, the amount of manual labour required to programme automation such as studying and designing the programme, coding the programme, and so on is enormous. So here, not only the welders or the welding industry is involved, but the electronic industry comes into the picture as well.”

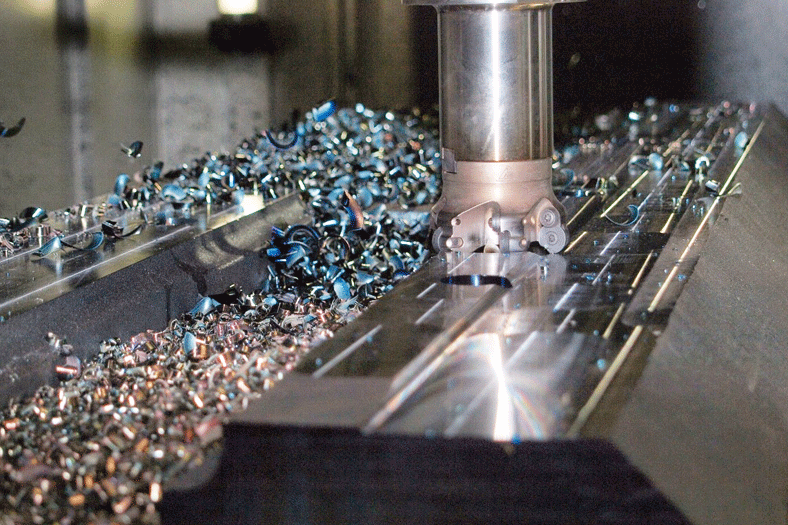

Oxy-fuel and plasma cutting for metal forming

The choice between the two processes can be made based on which process will ultimately yield the lowest cost per cut from amongst oxy-fuel and plasma after considering all possible variables. The basic nature of each process immediately dictates some choices when you are purchasing a new automated cutting table or retrofitting an existing one.

The speed of cutting also plays a vital role. While oxy-fuel cutting can reach speeds of up to 750 mm per minute, the plasma process can reach speeds of up to 200 mm per minute. This is true especially for lower cutting thicknesses of up to 40mm where plasma cutting pierces and cuts exceedingly faster than the conventional oxy-fuel process.

Vilekar says, “Modern CNC machines have up to four oxy-fuel torches and two plasma torches on the same gantry, giving the process versatility and flexibility. An oxy-fuel cut will have a heat-affected zone that is five to ten times larger than a plasma cut.

Oxy-fuel cutting has involvement of gases, and their surface finishing is quite rough. It is generally used where one does not need good surface finishing or in places where surface finishing is done after cutting. Pachpor says, “Choosing a process needs the right selection of material, desired surface finishing, economical process, and the frequency of cutting.”

Risk assessments in the welding and cutting process

Carrying out risk assessment during welding and cutting process is paramount for all industries. However, there is still a lot to be desired. Proper safety equipment must be used with these equipment like flashback arrestors, etc. Also, standard products should be used since any leakage might lead to big accidents.

It is always said that “safety is the first priority” for any process. Pachpor says, “During the welding and cutting process, many risk factors are involved; it is always good to understand and do safety exercises to prevent the measure of risk in the process.” Risks involves electric and noise hazards, exposure to fumes and gases, burns, welding and cutting safety precautions, lack of appropriate training, ensuring your workplace is well-ventilated and free of flammable materials. It is always the first priority to check these factors once before, during and after the welding and cutting process.

Advanced welding processes can minimise rework, increase production and offer a competitive advantage.

Aniruddha R. Vilekar, Head – Operations & Marketing, Ador Welding Limited

Automation will help the welding and cutting industry achieve the desired production target with desired quality.

Rakesh Pachpor, Proprietor, Root Machinery LLP

Today, there is a wrong notion that automation is going to cost or reduce the use of manpower. However, that is not the case.

R Srinivasan, Chairman, Indian Institute of Welding Technology

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.