SIL’s laser welding for industrial heavy applications

By OEM Update Editorial September 14, 2019 2:04 pm

Nowadays, laser technology is widely used for welding of any materials. The fiber laser technology with stable high power lasers from 4KW to 10KW has opened the gates for applications in thick metal welding of stainless steel (SS) and mild steel (MS). Even aluminium welding having applications in battery can be done successfully using laser technology. In fact, short wavelength laser welding systems enable us to weld materials with more thickness than the conventional CO2 laser welding.

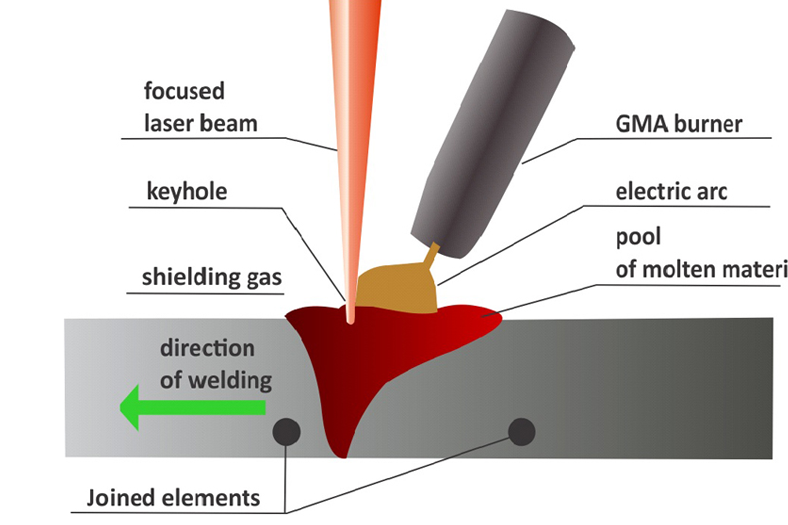

SIL has successfully developed applications of seam welding with no filler used for stainless steel with no porosity in weld material with 4KW fiber laser. Cut-weld-cut or weld-cut-weld system can be deigned as per application requirements. SIL welding machine can weld 10 to 12mm thick metals with 10KW fiber lasers without filler material. However, it is observed that autogenously weld require no or minimal gap between the two plates. If gap is uneven or more, the energy passes through the gap without heating the material. With this limitation, comes a welding GTAW process or GMAW process with laser assisted welding.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.