India: The next high-end machine manufacturing hub

By OEM Update Editorial December 11, 2018 2:29 pm

The big bang announcement of ‘Make in India’ strategy in realty calls for technology upgradation of Indian machine tool industry to manufacture high-end machines. So, here is an exclusive report on how Indian manufacturers are working on this opportunity to scale up the industry

Machine tools play an important strategic role in manufacturing diverse products beginning with automobile industry to high precision components for instrumentation and electronics industries, defence, aerospace, and so on.

V. Anbu, Director General & CEO, IMTMA, says, “Indian machine tool industry has been serving the needs of manufacturing sector by manufacturing a variety of machines. The industry is moving towards next level of growth to serve the demand for high-end machines.” Machine tool industry has started working with institutions to develop indigenous technologies and price competitive products. The level has to be widened to see more industries investing in R&D and innovations.

However, Mohini Kelkar, Director – Business Development, Grind Master Machines Pvt. Ltd. is of the opinion that as of now, this is the only area which is not completely addressed by India’s machine tool industry. As more and more manufacturing is happening in India, the demand of high-end machines is very rapidly rising. So, India’s machine tool industry should certainly work on this development. Kelkar says, “As for Grind Master, we are already offering high -end machines in our category of superfinishing and micro-finishing machines. These machines have all the advanced features and they also deliver the same results as any other global machines.”

The global push for IoT/ Industry 4.0 concept in manufacturing industries make its mandatory for machinery industry to develop and manufacture indigenous high-end machines that meets high performance and quality standards. This implies the Indian machine tool industry should review their present control technology, present mechanical design concepts implemented with a target for high-performance output. Ajey Phatak, Marketing Manager, Beckhoff Automation, Pvt. Ltd. says, “Considering the competition with East Asian machinery manufacturing companies using latest technologies, India’s machine tool industry for manufacturing needs a relook at the machine designs, control systems, machine cycle times and hence becomes of strategic importance.”

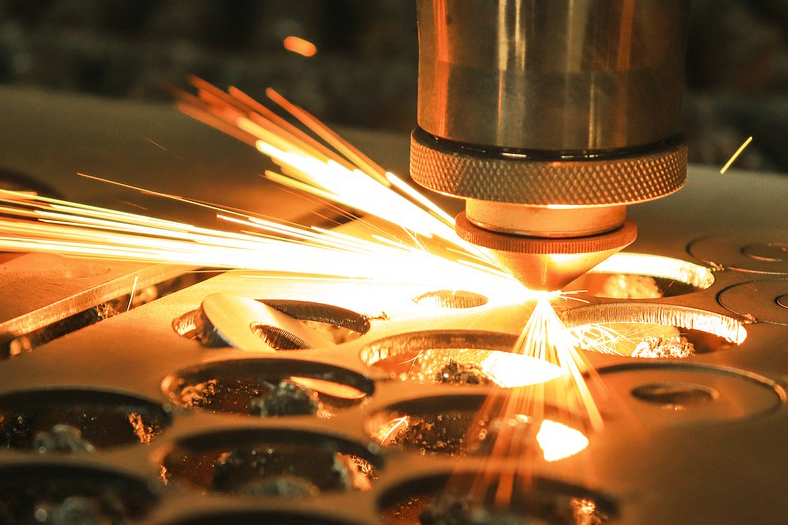

Looking towards India’s growth in recent years, it is observed that manufacturing industries have powered the economy. Maulik Patel, Executive Director, SLTL Group says, “In the recent years, we’ve seen a shift in the market implicating quality make of Indian machines. This is because our tool industry is performing very well in providing quality with lower incurring costs. In coming years, India would be key market for high-end machines.”

With the initiation of ‘Make in India’ and easing of FDI inflow in key sectors such as defence and aerospace, the country has become a fastest growing manufacturing hub. The demand of high-end machine tools is also growing proportionately. Harshal Dongaonkar, Asst.Manager – Western Region Sales, Hurco India Pvt. Ltd. says, “Hurco India makes high-end machines with the high degree of sophistication, technological precision, and reliability in performance to help customers to meet the international quality standards, superior finish and contour accuracies.”

Defence and aerospace manufacturing sector rising the prospects for machine tool industry

Aerospace and defence sector in India is now growing at a rapid pace. The Indian Government is taking all steps to ensure highest quality infrastructure for the same.

Dongaonkar says, “We, at Hurco India, are taking efforts to meet the special requirements of defence and aerospace industry with the latest technological innovations. Our legendary 5 axis and other high end machines are in use at many such companies in India.”

The opening of FDI in defence and entry of major players from private sector into the market is creating a large supply chain and opening up the market. Anbu positively says, “Demand will come from not just the large OEMs but also from the several sub-sectors including SMEs. We are at the tip of the iceberg and as time progresses the supplies to defence sector will increase.”

Military and defence sector fits right on the customised tooling manufacturing. Defence industry intakes components and machines in bulk which can be seen as positive indicator for both tooling and forming industry. Patel of SLTL Group says, “This industry is widely networked due to its customised demands and complex items which cover lot of industries under the umbrella. This will open up new possibilities for machine tool industry.”

The demand of defence manufacturing sector for high-end machines are not many times offered by India’s machine tool industry. Kelkar says, “In defence manufacturing, although, there are guidelines from top, very little has changed down the line; thus, the growth in opportunities which was expected has not happened to that extent.”

Another issue is that of volumes, there are parts of defence equipment which cannot be made in the same way as parts of automotive or engineering industry that we are all used to. “The cost of development becomes unfeasible due to low volumes and non-surety of business from defence sector. Thus, the industry initiative to develop somethings for defence is low”, adds Kelkar.

The demand coming from defence manufacturing sector is with latest technologies. Most of the defence manufacturing is with Technology JVs and the standards have been elevated to a newer level. Also, there are regulatory preconditions for localisation of component. Phatak says, “The prospect for local machinery industry have been on the rise. Albeit, they meet the performance standards.”

5 technology trends that will shape machine tool industry

India is preferred by global manufacturing companies as an outsourcing destination, due to cost competitiveness, favourable investment conditions, better engineering and designing capabilities with high end manufacturing sets ups to meet global requirements. Dongaonkar of Hurco India says, “With the growing influence of Internet of Things (IoT) and Internet of Services (IoS), coupled with Industry 4.0, it is very much certain that the Indian machine tool market is set to create new records, both in terms of quantity and quality.” Process automation, additive manufacturing and the rise of electric vehicles are the three core trends that are changing the dimensions of the machine tool industry.

Additive Manufacturing: Acts as a design enabler in validation of designs through prototyping

Artificial Intelligence: For accurate metal cutting when we graduate towards Bharat Stage VI in 2020 aiming for minimal carbon emission and sulphur. Metal cutting accuracies for engine parts are likely to become stringent.

CAD / CAM implementation in SME sector: Will help them in reducing dependencies on skills and use this process for bringing out high precision products.

Fibre laser tools: Effective for metal processing, cutting the cost and delivering good productivity. Metal cutting, marking, engraving, welding, micromachining and so on have been taken to a new level.

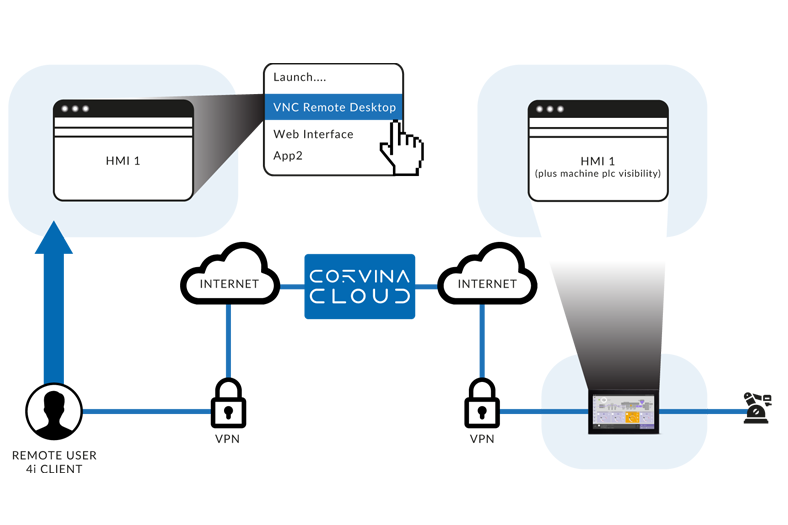

Industry 4.0, machine tending automation, robotic automation, 3D Printing technology are the top technological trends that Kelkar of Grind Master Machines vouch for. The technology trends in machinery are modular machine concept, integrated machine learning, AI, in process data acquisition etc. This requires thorough review of the control system architecture and compliance to standards such as EtherCAT, OPC UA for interoperability and data exchange requirements. Data Analytics with AI and ML by the machine control systems will be the drivers for new generation machine tools, concludes Phatak of Beckhoff Automation.

“We are at the tip of the iceberg and as time progresses the supplies to defence sector will increase.”

V. Anbu, Director General & CEO, IMTMA

“The prospect for local machinery industry have been on the rise”

Ajey Phatak, Marketing Manager, Beckhoff Automation, Pvt. Ltd.

“High-end machine manufacturing is not completely addressed by India’s machine tool industry”

Mohini Kelkar, Director – Business Development, Grind Master Machines Pvt. Ltd.

“Our tool industry is performing very well in providing quality with lower incurring costs”

Maulik Patel, Executive Director, SLTL Group

“With the growing influence of upcoming software, the Indian machine tool market is set to create new records, both in terms of quantity and quality”

Harshal Dongaonkar, Asst.Manager – Western Region Sales, Hurco India Pvt. Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.