Cranes: Lifting the manufacturing industry

By OEM Update Editorial September 12, 2018 3:57 pm IST

One of the very popular techniques used to build pyramids, where large stones are lifted and transferred to particular height to build pyramids. These early cranes consist of a long wooden beam which are connected to rotating base. Modified version of these lifting and moving load techniques is nothing but crane and hoist.

Cranes and hoists

Cranes can move the load in horizontal direction and vertically as well. Crane incorporates the use of other simple machines including hoist to develop a more effective mechanical device that will make moving loads and objects easier and faster.

Now-a-days, cranes and hoists are integral part of any manufacturing and construction industry. Hoist is a simple device used for lifting and lowering loads vertically while crane is a complex device used for moving loads in different direction.

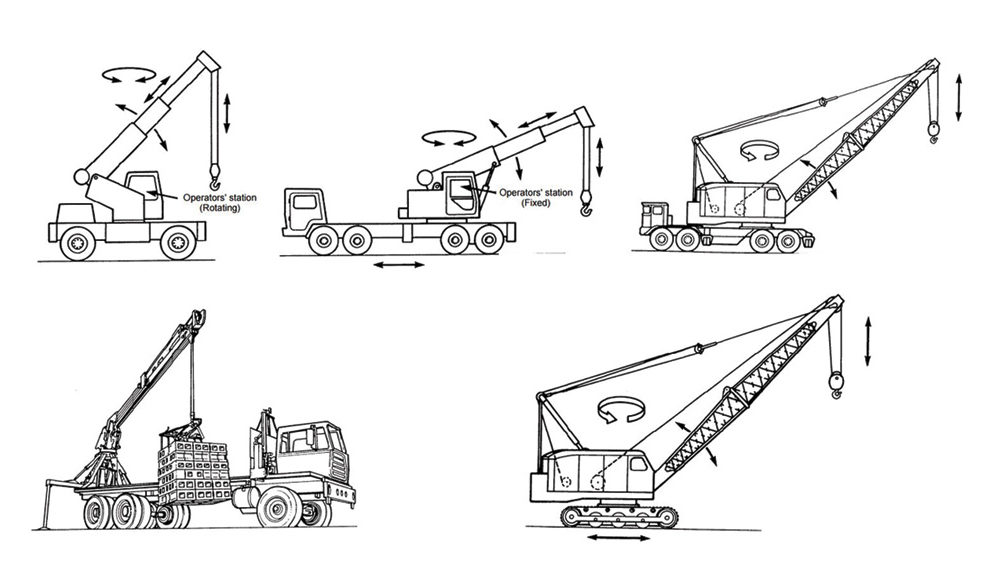

There are different types of crane which are used in construction industries such as mobile cranes, telescopic crane, tower crane, truck mounted crane, rough terrain crane, loader crane, overhead crane, hammerhead tower cranes, straddle cranes, monorails and underhung cranes.

Design of cranes

Safety is the most important factor to be considered during crane designing. A designer must need to consider the place where the crane will be used, up to what weight will it need to do the lifting and the load calculations to select the bill of the crane’s material. As per design, a manufacturer needs to make the steel components and then assemble it. The manufactured steel parts go through various inspection to understand structural flaws. Before bringing the crane into actual use, the manufacturer does testings to verify the load carrying capacity, the strength of the swing of arms and so on.

Fasteners

Machine is an assembly of different parts arranged in definite order and used to transform energy for doing some useful work. Connection between two parts can be either temporary or permanent. In general, fasteners are used to create non-permanent joints; joints can be removed or dismantled without damaging the joining components. Fasteners plays vital role in mechanical industry. Fasteners such as key, pin, retaining rings, are frequently used with shafts. Nut, bolt, screws, studs, are threaded fasteners are used for non-permanent joint. Temporary joints are screwed joints, keys, cotter and pin joints and pipe joints.

Welding

In permanent joints, the connected parts cannot be easily separated; they are riveted and welded joints. Welding is a technique of joining two metal parts by fusing them together; a permanent joint. In the construction of boilers, ships, bridges, steel structure etc. uses riveted joints. However, rapid development of welding methods has replaced riveted joints.

Types of welding process

• Pressure welding or forge welding

• Fusion welding

• Fusion and pressure welding

• Lap joint

• Butt joint

• Tee joint

• Corner joint

Types of welded joints

• Back

• Fillet

• Plug

• Square

ARES Mechanical for designing

ARES Mechanical, the 2D MCAD solution can help user to design and build, design a robust product of crane and hoist using readily available fastener and welding features.

ARES Mechanical includes a wide range of MCAD-specific features, including:

• Library of standards-based, ready to use mechanical parts: including bolts and screws, nuts, pins, washers, holes and many others

• Advanced detailing features such as balloons insertion, weld and surface finish symbols and more

• A specific user interface based on interactive and contextual ribbons designed to offer high productivity and easy to learn for most mechanical engineers (especially 3D CAD users who have little experience with DWG-based CAD software one of them is ARES Commander)

Authored article by:

Mr. Rajesh Garg

Managing Director, Graebert India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.