IIoT is the need of the hour

By OEM Update Editorial June 12, 2018 5:29 pm IST

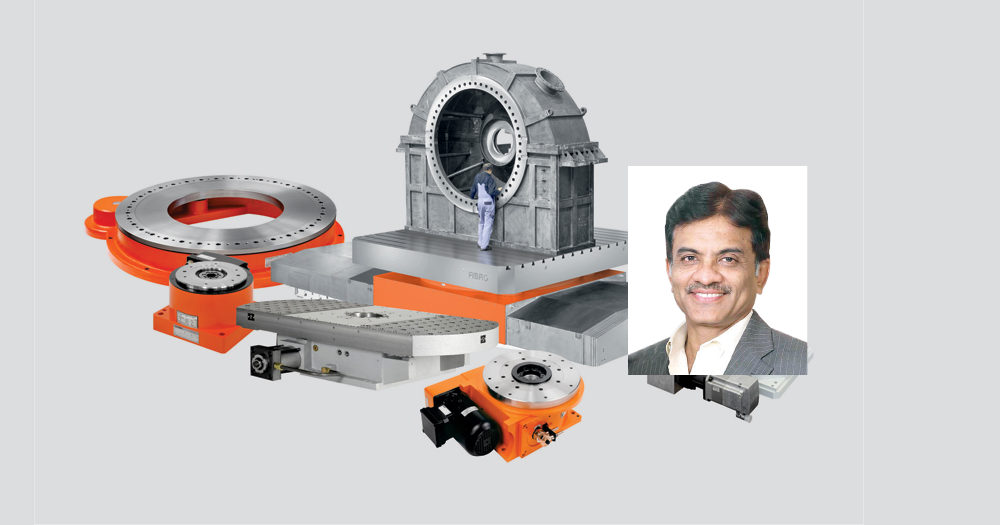

Vivek Nanivadekar,

Executive Director, Fibro India Precision Products

Today the global customer wants to outsource labour intensive processes or hazardous processes from the country like India. So we can not eliminate or reduce the labour but we need to integrate the laborious processes with IIoT to deliver the competitive output.

How does the future look for IIoT in manufacturing?

It is a long way to go. As I see the manufacturing is on the first step of IIoT. It is top driven in an organisation and it is driven from external for manufacturing sector. It starts from the service industry first and then service industry will drive manufacturing sector subsequently. Actually, it should be vice a versa. There are many basic issues like ERP, hardware, software, internet speed, data processing, data privacy, computer literacy of the people etc. etc. Today not all MSMEs are using ERP. Secondly different ERPs do not talk with each other digitally. The technology in hardware and software keep changing rapidly making old one obsolete. Another important factor, the ‘Industry 4.0’ is the part of IIoT. Today, the manufacturing sector has started thinking about it.

Nevertheless, IIoT is the need of the hour. Whether one likes it or not, he has to comply with it. The direction is set but it is difficult to predict as where we would reach by the end of 2018. Rather manufacturing would be impossible without IIoT. Today the ‘Digital Manufacturing’ is the buzzword. But how much has been implemented? or How many have initiated the process? I believe today most of us from manufacturing industry are trying to understand it. We dont know how it is going to help in reducing the cost of manufacturing. Or will it increase the cost of manufacturing? Will it increase the efficiency? Will it increase the output? Will it improve my margins? I think the time will answer these questions. Certainly it will help in improving the planning of production but how it will take care on emergencies without manual intervention?

Is it necessary to automate each and every manufacturing process? If yes, then whether we will be globally competitive? Today the global customer wants to outsource labour intensive processes or hazardous processes from the country like India. So we can not eliminate or reduce the labour but we need to integrate the laborious processes with IIoT to deliver the competitive output.

Which industries will drive IIoT adoption in 2018?As mentioned above the service industry will adopt IIoT quickly or rather many sectors of service industry like hospitality, courier, retail merchandising etc. have already implemented it to the great extent. In manufacturing industry the implementation would start from supply chain and other peripheral services before it gets implemented in the core manufacturing processes.

The word IIoT encompasses very large or rather infinite things. One has to be selective about the things of his manufacturing processes where he finds IIoT useful.

The distribution channels along with logistics have already started adopting IIoT by implementing CRM or SRM. These are quite important tools which help us in determining the trends, buying patterns, delivery performance etc. Now the markets have become quite dynamic and the business cycles have shortened. If we have to align with the market dynamics then there is no alternative but IIoT. The inventory management is very important aspect of the business cycle and the data analysis will help you to gear up to suit the market situations. Otherwise the manufacturing finds itself on the wrong side of the market situation i.e. When the market demand is high, you are not geared up and when you are geared up the market suddenly deeps. To avoid such situation we need to use smart solutions.

Could you discuss about your company’s preparedness in this front?

We have adopted and implemented ERP, CRM, and soon we will gear up with web shop, job scheduling, SRM etc. We have also automated the despatches by using Barcode reader, packing stations etc. But we have long way to go. The next step would be data analysis to take the right business decisions. We are concentrating on developing error free supply chain which enables our marketing/sales team to commit the accurate delivery to the customers. I think we have geared up less than 50 per cent of our requirement and hope to reach 80 per cent by the end of this financial year.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.