Right lubricants improve machine performance

By OEM Update Editorial April 11, 2018 5:03 pm IST

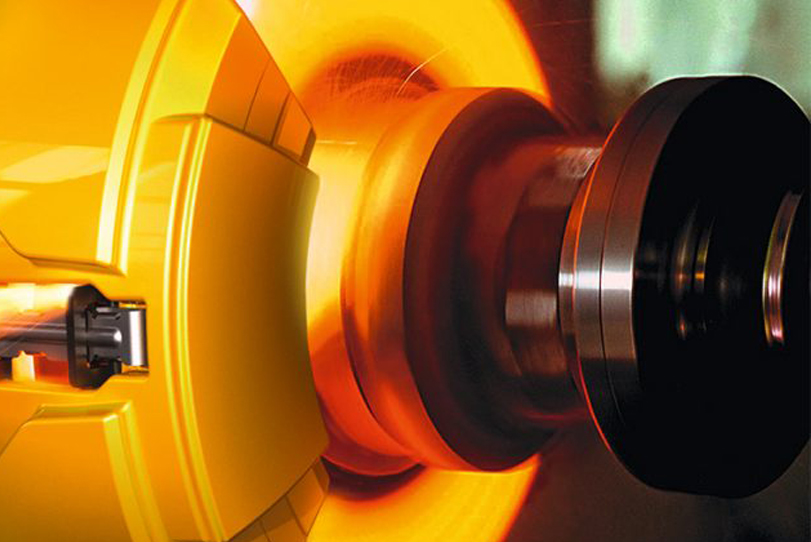

Manufacturers aim at improving the performance and health of CNC machines. There are several different variables that need to be taken into consideration in order to achieve it. Most important are metallurgy, evolution of tools, higher productivity, lowest downtime and correct lubrication process.

Types of lubricants

There are two types of lubricants used in CNC machine operations. First is the cutting oil also known as production oil which is directly responsible for machining performance. Second is lubricants that are used for lubrication of internal machinery mainly slides, tool movement mechanism, hydraulic system.

Classification of cutting oils

Cutting oils are classified into two types – neat and soluble. Neat oils are used as is whereas soluble oils are mixed into water before subjecting them to application. Several factors such as type of material being machined, type of operation, operating parameters like speed, feed, depth, required tool life need consideration along with price while choosing the right cutting oil. OEMs and mid to large size customers expect coolant management service and overall cost per component improvement while selecting the fluid. Gulf offers a wide range of neat and soluble cutting oils under brand names Gulfcut and Gulf Emulsil for a range of operations on different materials. These oils are formulated using selected base oils and additives in right proportion to achieve maximum efficiency at the same time improving tool and oil life. Gulf oil works closely with the customer right from checking water quality, training concerned team on cutting fluid handling and storage, emulsion preparation and usage of instruments to maintain concentration and pH.

Hydraulic oils, waylube oils, greases

Second product line includes hydraulic oils, waylube oils, greases as a part of machine operation and maintenance. Location of lubrication points as well as time and human constraints make it impractical to manually lubricate these points. CNC machines come equipped with lubrication system for lubricating internal machinery. Reservoir, pump, supply line, and metering valves are basic components of these systems. Basic adjustments, maintaining reservoir pressure, filtration are essential for effective performance.

Hydraulic oil is used for clamping of jobs and tool movement. Quality of hydraulic oil is critical for consistent hydraulic response, protection of hydraulic system components viz. pump, valves and hence uninterrupted superior machining performance. Waylube oil on the other hand is used for horizontal or vertical surfaces and where machine parts move over the top of each other. Waylube oils must hold in place to do their job and tackifiers are added to help the same. Slideways are prone to stick slip motions and to overcome friction due to it slideway lubricants are formulated with inbuilt anti stick-slip property. Hydraulic systems do not require this property. It is unwise to use hydraulic oils in place of slideway oils for mere rationalisation and saving cost. Gulf oil has complete range of industrial lubricants: Hydraulic – Gulf Harmony, Waylube – Gulfway, Gear oil – Gulf EP lubricant for specific applications.

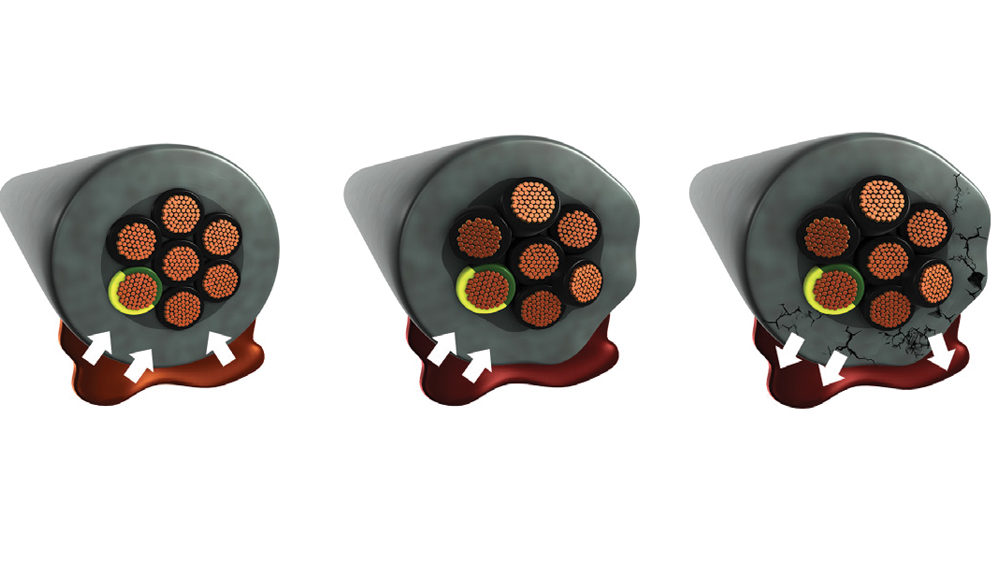

Soluble cutting fluidSoluble cutting fluid is a complex blend of various components required for enabling emulsion formation, lubricity, rust and corrosion prevention, impart anti wear and EP properties. Global and local legislation restricts the use of certain chemicals such as boric acid, formaldehyde releasing biocides, chlorinated additives, and sodium nitrite. These components are hazardous to operators and environment. Gulf follows very stringent filters while selecting additives and believes in offering operator and environment friendly solutions to its customers.

Author:-

Vivek Kale,

Assistant Manager – Technical Services,

Gulf Oil Lubricants India Ltd

vivek.kale@gulfoil.co.in

gulfoil.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.