COBOTS: Shaping key trends in automotive manufacturing

By OEM Update Editorial March 13, 2018 3:43 pm IST

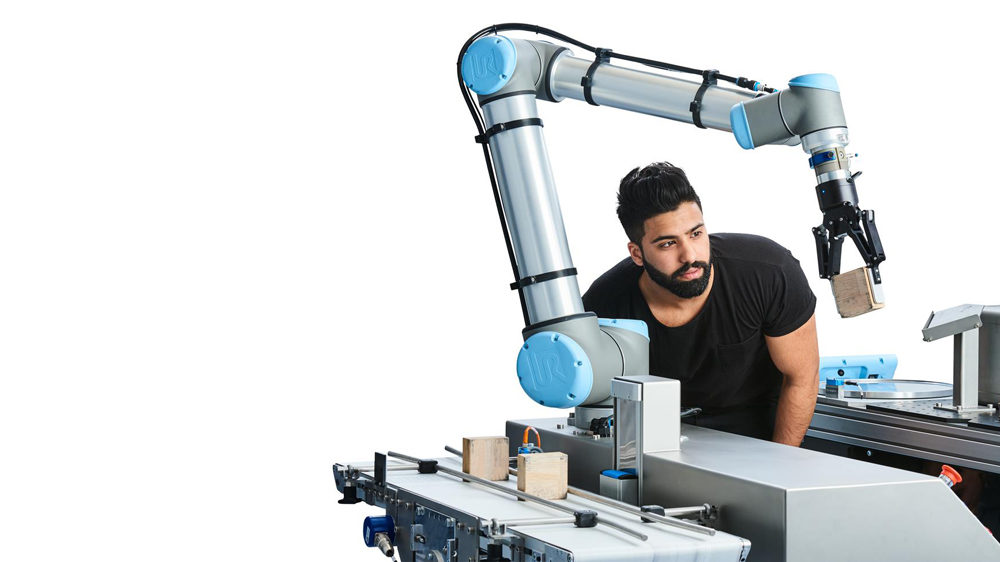

The most beneficial aspect of cobots is their flexibility. In modern automotive manufacturing, these robots work with humans to give them increased productivity in a variety of roles.

Technological changes, addition of new features in automobiles, rising number of parts that go into each vehicle and need for higher production are factors that have necessitated automation. In 2018, automation in automotive manufacturing is considered as essential as human labour is costly and unpredictable, whilst selectively implemented industrial automation helps automakers eliminate human errors and ensure increase in precision and productivity.

The latest trends in automotive manufacturing include the accelerated adoption of collaborative robots or cobots. The most beneficial aspect of cobots is their flexibility. In modern automotive manufacturing, these robots work with humans to give them increased productivity in a variety of roles. They are easily built and provide safety features to protect their human counterparts.

To make robotics and collaborative solutions more accessible, many robotics manufacturers have adopted a “service” policy that offers more accessibility to start-ups and cost-sensitive industries. By lowering the barrier of entry, manufacturers can also get their robotics solutions out in the field quickly and without the amount of testing needed to sell them outright. This is yet another step in the shift towards a robot service economy.

Universal Robots is the manufacturer of advanced, user-friendly and light industrial robotic arms, with their headquarters in Denmark. Universal Robots’ UR3, UR5 and UR10 are inexpensive, light weight and easy to program. They have also released a new generation of robots, making it even safer for humans and robots to collaborate.

The third-generation UR robot arm features eight new adjustable safety-rated functions, making it the only robot in the world that adapts advanced safety settings to each specific application. The new UR5 and UR10 robots also come equipped with True Absolute Encoders eliminating the need for re-initializing the robot, while enabling automatic start-up and easier integration into other machinery. The new robots offer updated hardware technology and an improved safety system.

Author:Pradeep David,

General Manager,

Universal Robots – South Asia

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.