A Real World Approach to the IIoT

By OEM Update Editorial October 9, 2017 3:47 pm IST

This article explains how adapting the IIoT helps to operate a plant with optimal efficiency.

Process plants today are faced with meeting increasing performance demands, which starts with the plants running at maximum efficiency. But, the path to achieve maximum efficiency is filled with many road blocks, such as unplanned equipment breakdown. To address the untimely breakdowns, a facility needs to predict undesired process conditions and equipment failure before they take place. Currently, most facilities have a run-to-fail approach to address untimely malfunctions. Unplanned downtime at a mid-sized refinery can cost up to $40 million a year. To ensure uptime, companies send field technicians to perform routine diagnostic inspections and maintenance as per fixed schedules. This is a costly, labour intensive process with minimal assurance that failure will not occur between inspections. Companies have also adapted other methods like Advanced Process Control (APC), defined operating boundaries with their alarm systems and creating Key Performance Indicators (KPIs). Apart from this, companies have also sought help from local experts to resolve operating problems but these measures are difficult to sustain as they are dependent on dedicated on-site personnel.

Therefore, a need arises to address these staggering loss-making numbers in a process industry. In a highly competitive global market, industrial organisations seek “Digital Intelligence” to manage and operate thousands of assets from a single site or across an enterprise to address critical operating demands. Manufacturers today are looking for solutions that can interpret a vast quantity of data to analyse impact on performance. To support the multiple monitoring and support applications necessary for manufacturing facilities, data needs to be churned into information and delivered with context so it can be understood and used in numerous ways by various people. A growing number of players in the global market are adapting the Industrial Internet of Things (IIoT) to optimise their business performance.

Manufacturing plant operators are being enabled by IIoT to improve the operational efficiency and reliability. They are doing this by capturing and analysing data to identify and predict the adjustment and maintenance of process equipment and proactively servicing installed assets before problems arises. IIoT allows companies to do more with their current systems and extend their business processes to enhance monitoring and reduce time-to-action. An IIoT environment, or a connected plant as we know it, offers companies the ability to aggregate data from existing sources, create additional data sources and bring these together in a cost-effective way to identify breakdown patterns and derive insight through analytics that were not previously possible. It can transform work process from manual and reactive to automatic and proactive, helping users to avoid unplanned downtime, and improve performance and safety.

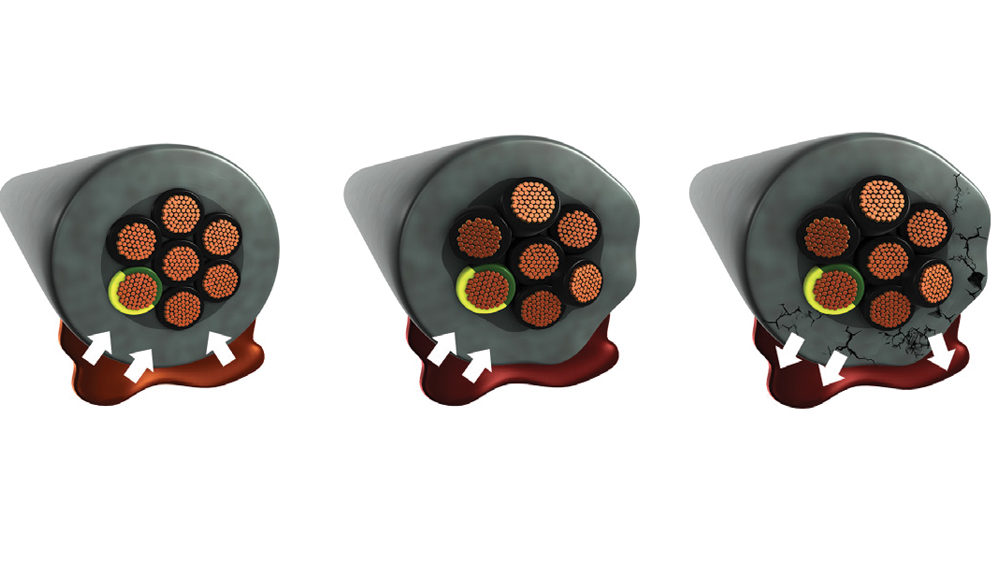

An IIoT-enabled plant uses a combination of advanced sensors, automation systems, and cloud technologies integrated with current systems and data analytics to become smarter. This provides the ability to locate data in a cloud environment where it can be accessed and analysed with analytical tools. For example, an equipment vibration reading would be sent to the plant’s Distributed Control System (DCS) as a single value, whereas rich dynamic data stored in the cloud would allow engineers to study the harmonic signature of a bearing or shaft to determine the root cause of a pending asset failure. Currently, in most cases, dynamic data is only employed by specialists in custom applications – limiting its accessibility by other users in the plant. It is important that IIoT not be just about capturing sensor data. Information needs to be put into asset context structure. Merely operating on tag-based data will not ensure a repeatable and scalable solution. Processes are instrumented for control rather than reliability or optimisation, and as a result, much of the ‘derived data’ important for prediction and decision –making is in locked spreadsheets and other standalone tools. It is essential to calculate this data on an on-going basis and bring it into the IIoT environment where continuous runtime analytics can examine historical performance for use in machine learning algorithms. Furthermore, IIoT solutions should not solely rely on statistical models to detect deviations from normal. Having a fundamental, physics-based model creates a digital twin, with a virtual representation of the process or asset located in the cloud. This allows users to model and compare expected process performance against actual results, and then view these deviations as early indicators of health degradation.

Adoption of IIoT has created economies of scale for smart sensors, connectivity, analytics and robust software platforms. This change is driving the adoption of enterprise-level performance management, process monitoring, predictive maintenance programs, and business transformation with the goal of eliminating unplanned downtime and reducing operating costs – all while maintaining product quality and compliance. Though one may ask, what does IIoT mean in numbers? IIoT has multiple benefits in terms of customer value:

• Increased asset utilisation up to 10 per cent: Plants can reduce unplanned downtime by predicting and providing proactive responses

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.