Boost in productivity thanks to automation

By admin August 12, 2016 4:12 pm

Since 2010, SPECK has consistently relied on automated machine tools from DMG MORI Systems in order to boost capacity in its production

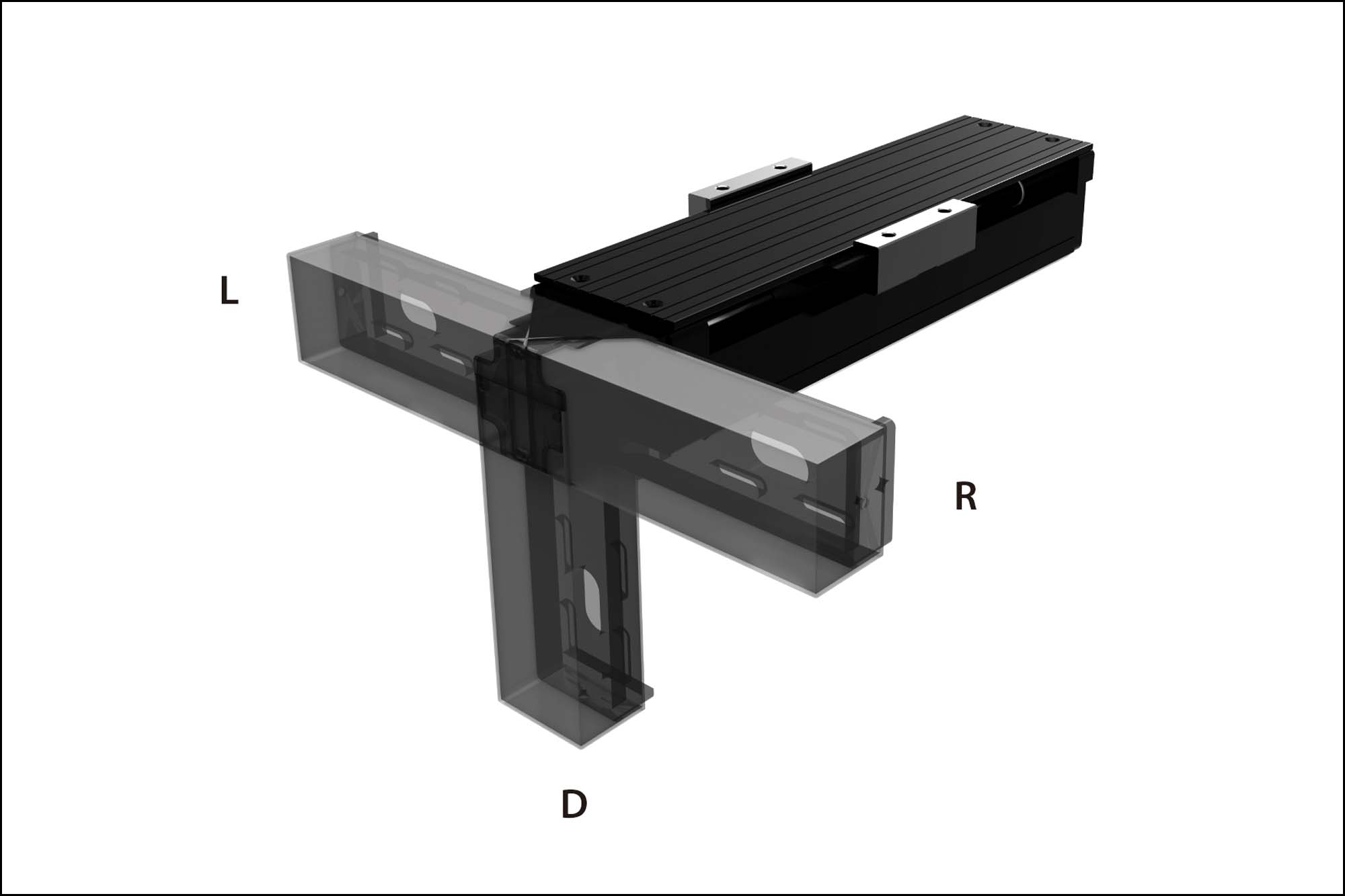

SPECK PUMPEN Walter Speck GmbH & Co. KG from Roth produces more than 250,000 pumps and pumping systems for industrial applications a year. The company has been supplying customers in over 40 countries for more than 100 years. SPECK produces its specialised products primarily for customers from the medical technology, chemicals and pharmaceutical industries, for cooling and temperature control equipment and for the plastics industry. The high level of specialist expertise of its more than 450 employees worldwide is supported in mechanical production by state-of-the-art machine tools. Automated systems from DMG MORI have played a significant role here since 2010, as the latest investment proves. For this DMG MORI Systems linked a MILLTAP 700 and a CTV 160 using an automation solution.

When asked about the core competences and the differentiation features of his company, the CEO Wolfgang Krüger mentioned especially its innovative and application-orientated capability. “We unite this with a high level of flexibility in production and assembly in the manufacturing of our many different components and with short delivery times.” To appreciate the importance of this statement it is worth taking a look at the product programme. The company’s website mentions no less than 26 or rather 33 areas of application in its fluid and vacuum pump divisions. Its list of references includes standard applications in machine tool manufacture, in laser and welding technology or in agricultural and rail vehicle manufacture as well as the proverbial exotic use of special pumps for tobacco moistening. To accommodate this multitude of applications SPECK in Roth offers a total of 18,000 different pump versions in over 80 series – and often in different performance classes as well. So it is no surprise that there are no standard parts in the production halls. “The average batch size in mechanical production is just 50 to 100 parts.”

In view of the outlined requirements profile, the question as to the importance of its own production is easy to answer. Wolfgang Krüger points out the close interaction between machine tool, tool and cutting material and stresses: “The autonomous development of new or alternative manufacturing strategies and continuous further development in all the sectors mentioned are what boost the productivity of our manufacturing processes.” The company would lose a big portion of relevant expertise if it purchased workpieces from outside. “Added to this is the extremely high demand placed on the quality of the pumps.” In order to maintain a high degree of efficiency, the gap dimensions of the SPECK pumps are often in the range of a few hundredths of a millimetre. Such quality pressure is further intensified by the trend towards ever smaller pumps with an ever higher degree of efficiency.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.