Industrial automation: Why it matters

By admin April 13, 2016 5:45 pm

Sudhir Dembi of Schneider Electric India observed that industrial automation is ahead of most other industries in the readiness for the IoT and more specifically for the IIoT

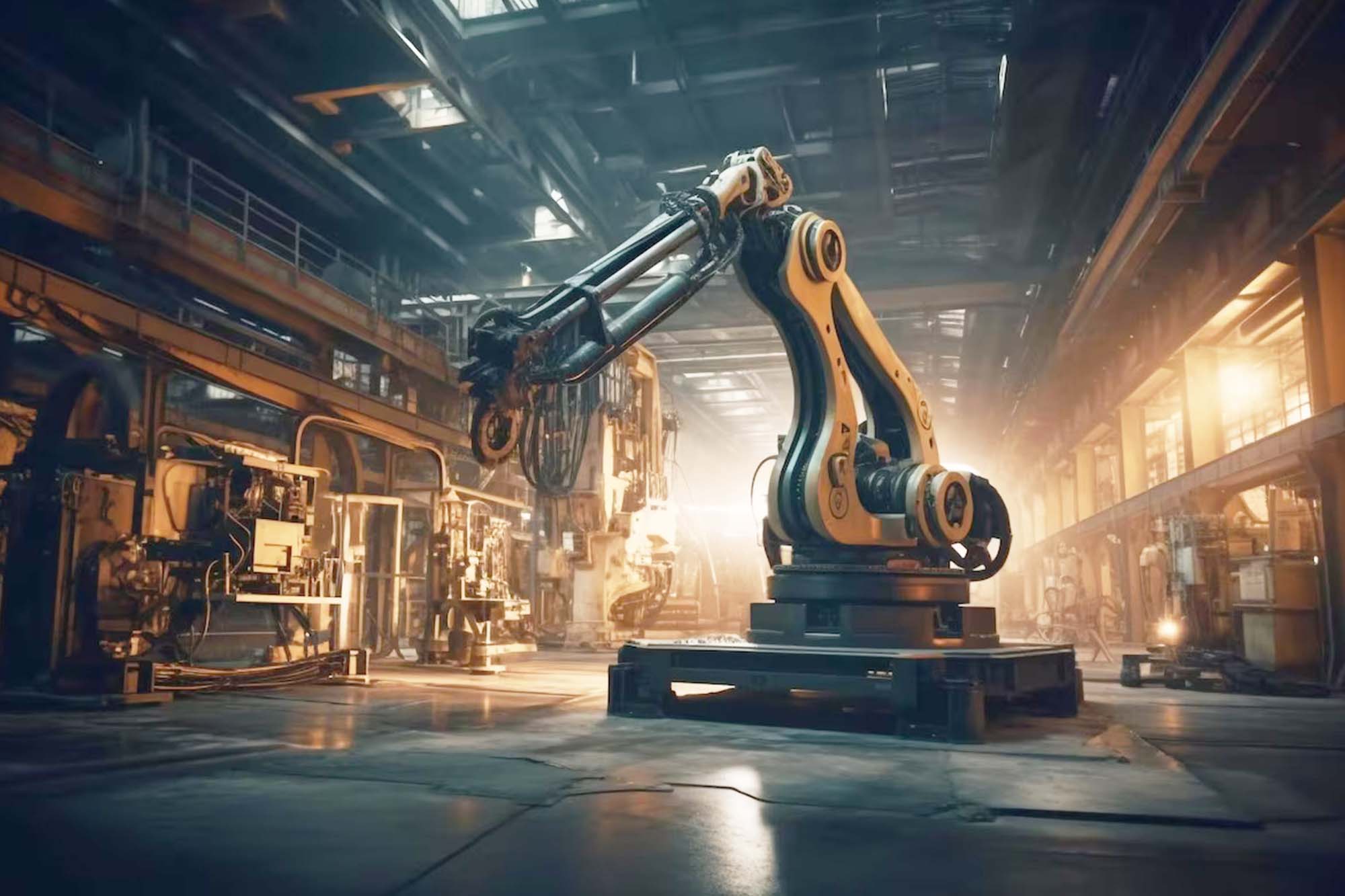

The ongoing quest for increased efficiency and productivity is putting more and more pressure on operational and maintenance excellence as is the need to feed fast growing businesses in developing economies like India. Industrial automation is currently in its adolescent phase but is catching up very quickly. Industrial automation is ahead of most other industries in the readiness for the Internet of Things (IoT) and more specifically for the Industrial Internet of Things (IIoT). When one looks at the deployment of the sensors, actuators, and low-level devices that are needed to enable IoT or IIoT, industrial automation has an advantage.

IoT and increased industrial performanceThe IoT is coming and in some industries is already here but is in its infancy. Most industries are waiting on the deployment of the low-level connected devices to enable IoT in that industry. Industrial automation on the other hand already has over a billion connected devices deployed. On a curve of connected devices needed to make IoT effective, industrial automation is much higher up the curve than other industries. Using data to improve industrial performance by connecting things to each other – this is happening now. Through wireless technologies, low cost sensors and using advanced analytics. In practice, this is a decision support system for complex manufacturing operations. However this is not to say industrial automation is done growing with respect to IoT, Where Industrial automation may be lagging other industries is in the gathering of useful data and the use of this data. Much of the information that resides on the end device that could be useful is not gathered. Data that is not consumed at the field or process levels in the traditional industrial automation hierarchy is not gathered. Now we must realise that the value of this data that is not being collected is increasing and industrial automation networks are starting to collect the data and communicate this data farther up the hierarchy.

Smart Factory A ‘Smart Factory’ can be defined as an integrated and fully interconnected network of smart assets working together in an intelligent and coordinated manner, managing every aspect of the manufacturing process from end-to-end. Each smart asset is equipped with its own “brain” and a database of all available data about itself, enabling it to present useful information or “facets” to different operation personnel, and is also equipped with its own intelligence to allow it to optimise their own productivity and efficiency. Today’s concept of industrial automation is based on having one centralised “brain” collecting information from the manufacturing assets to facilitate production decisions. In ‘smart manufacturing’ the intelligence is decentralised, with each of the smart assets within the factory, having full information about itself, and equipped with the processing power to optimise their own productivity and efficiency. These smart assets are also hyper connected to optimise and coordinate each step of the manufacturing process.

Smart assets are already available in the market today with the new generation of process automation systems and smart field instrumentation. Hyper connectivity that allows smart assets to be fully interconnected from the field to the enterprise is also already available in the market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.