Stay ahead with welding trends by CLOOS

By Staff Report April 7, 2025 12:48 pm IST

CLOOS is keeping pace with industry trends and identifying challenges in welding technology that can be addressed with its innovative solutions.

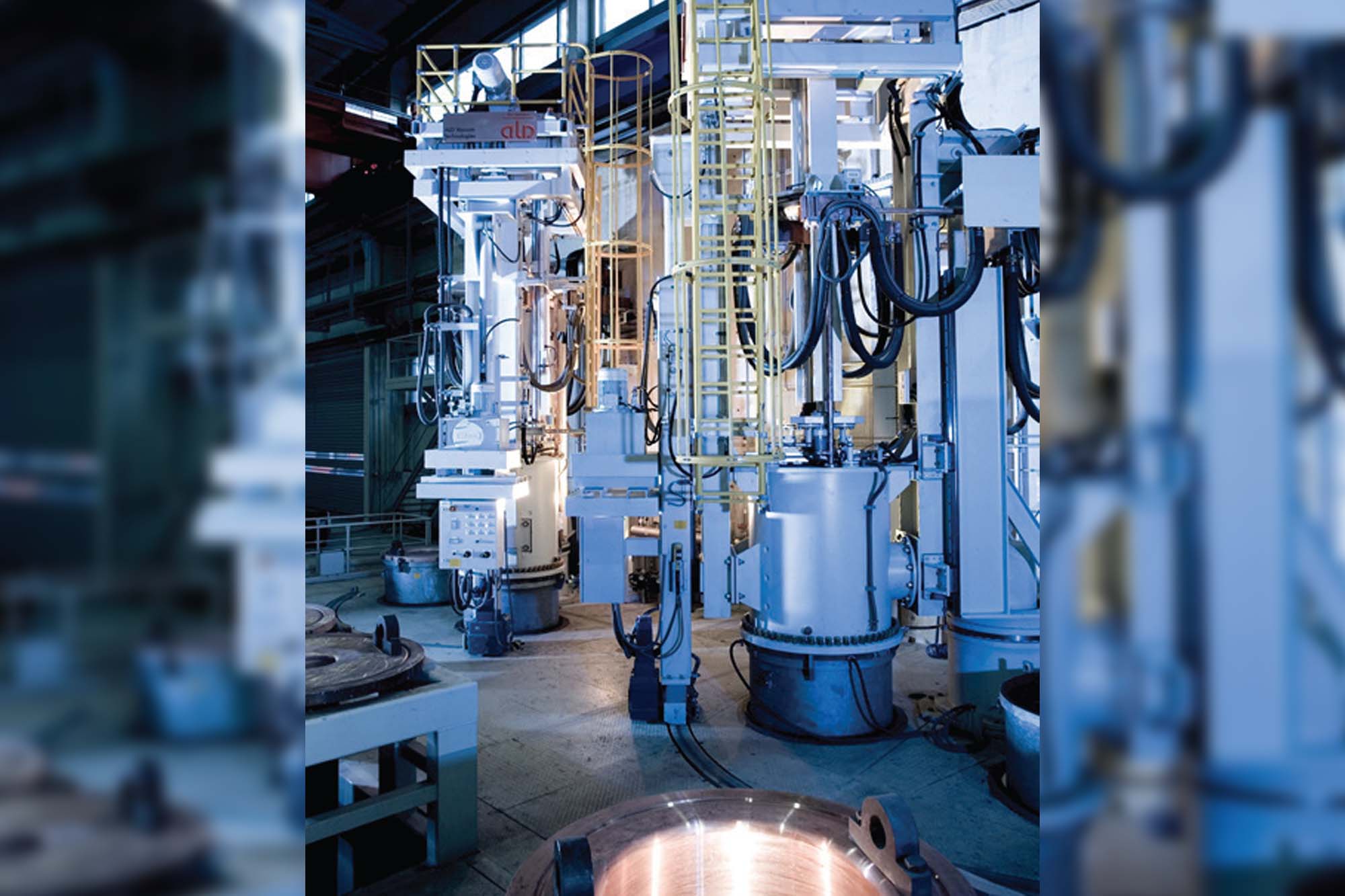

Trend 1: Growing Automation

The rise of automation continues to reshape welding processes, enhancing efficiency and precision. CLOOS uses advanced technologies to integrate robotic welding solutions seamlessly. Their all-in-one approach ensures easy integration and no gaps between processes, keeping the welding operations of users up with the demands of the modern era.

Trend 2: Sustainable Welding Practices

he welding industry will switch to sustainable methods in 2025. CLOOS offers environmentally friendly solutions such as welding fume extraction to minimise environmental impact, protect employees, and optimise energy consumption. The aim is to create a sustainable future through responsible welding.

Trend 3: Skilled Workforce Shortage

The shortage of qualified welders remains challenging, but CLOOS is closing the gap. QINEO ArcBoT and compact robot cells by CLOOS make welding accessible to a range of operators. This ensures that welding is preserved while a new generation of welders can be trained.

Trend 4: Digitalised Production

The digital revolution is in full swing, and welding is no exception. Monitoring and controlling production in real time is of paramount importance. With CLOOS C Gate, all digital solutions are in one place so that users can check production data effortlessly.

How CLOOS can help:

Interlinked robot welding solutions: Increase your productivity with precision and speed.• Sustainable technologies: Harmonise your welding processes with environmental goals.

• Human-robot collaboration: Encourage a versatile workforce and eliminate the shortage of skilled labour.

• Digitalised production: Real-time monitoring and control on an integrated platform.

Trend 5: Optimised welding preparation is possible with the CLOOS Arc Sensor Simultaneously measuring and welding to ensure sustainability and quality. Without a laser, the CLOOS arc sensor enables measurement and welding to occur simultaneously with minimal loss in time. The welding torch oscillates along the edges of the weld seam, measuring for differing values on Stay ahead with welding trends by CLOOS CLOOS is keeping pace with industry trends and identifying challenges in welding technology that can be addressed with its innovative solutions. CLOOS Fume extraction torch for manual, Cobot and Robotic welding CLOOS Welding helmet with fume CLOOS Compact cell with Fume extraction Sumon Mitra COO, Cloos India Welding Technology Pvt. Ltd. ADVERTORIAL April 2025 n 49 either side. The computer-based robot controller then adjusts the welding head position to place the seam in the centre of the joint and corrects the distance of the welding torch to the workpiece if the measured values are not the same on both sides. At the same time, workpiece distortions are corrected without the need for additional parts.

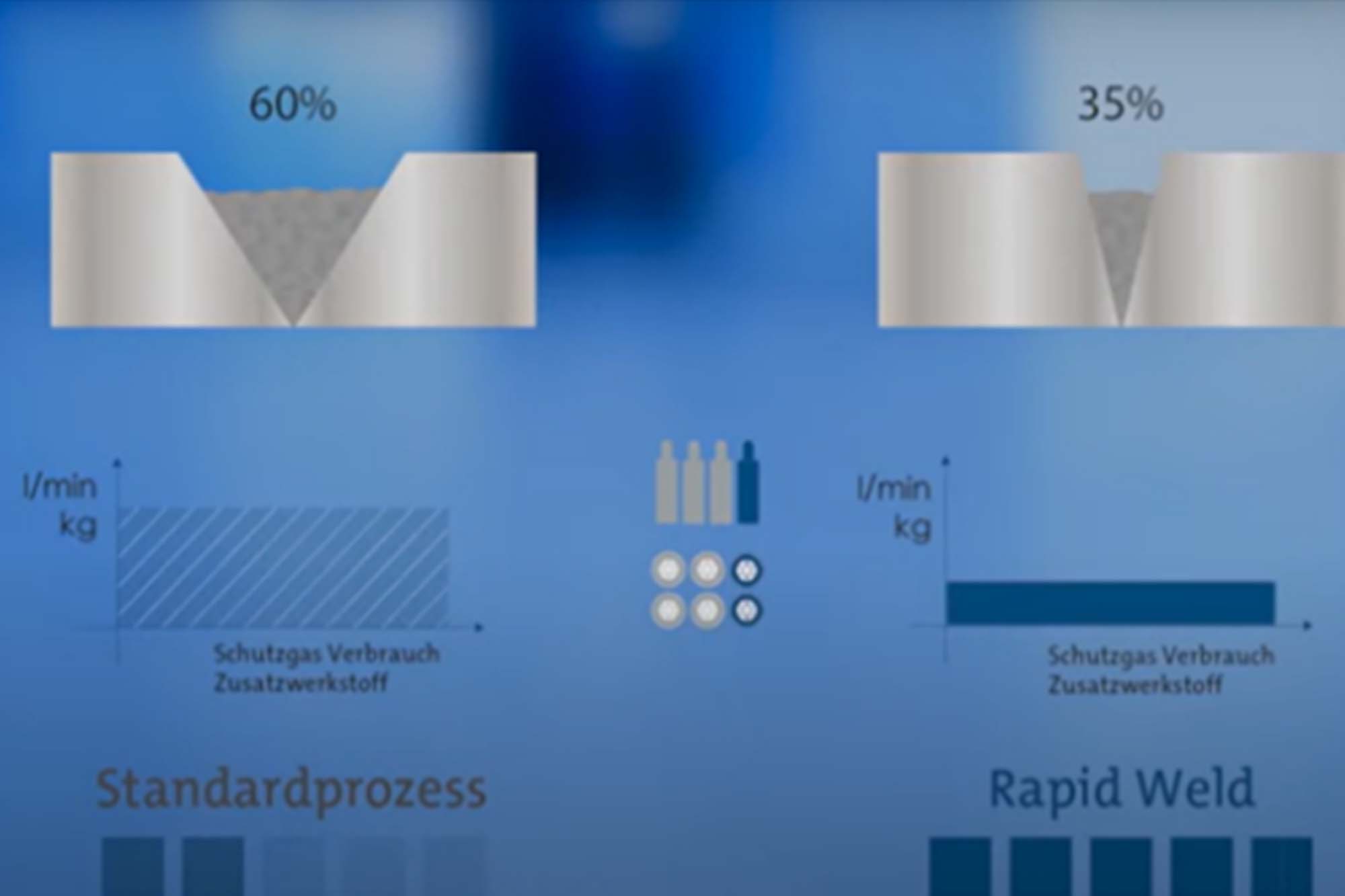

Trend 6:- Reduce cost by energy savings and less post-weld work by innovative welding process

Since 1919, Carl Cloos Schweisstechnik GmbH has been one of the leading companies in welding technology. CLOOS developed more than 15 types of welding technology. Out of those, two innovative welding processes (Rapid Weld and Speed Weld) significantly reduce the use of filler material and shield gas due to small opening angles with high welding speeds because of the powerful arc. Users benefit from the excellent weld quality due to the deep penetration. They can avoid extensive reworks as spatters and undercuts are reduced. Users can also reduce the welding time as considerably fewer welding layers are necessary.

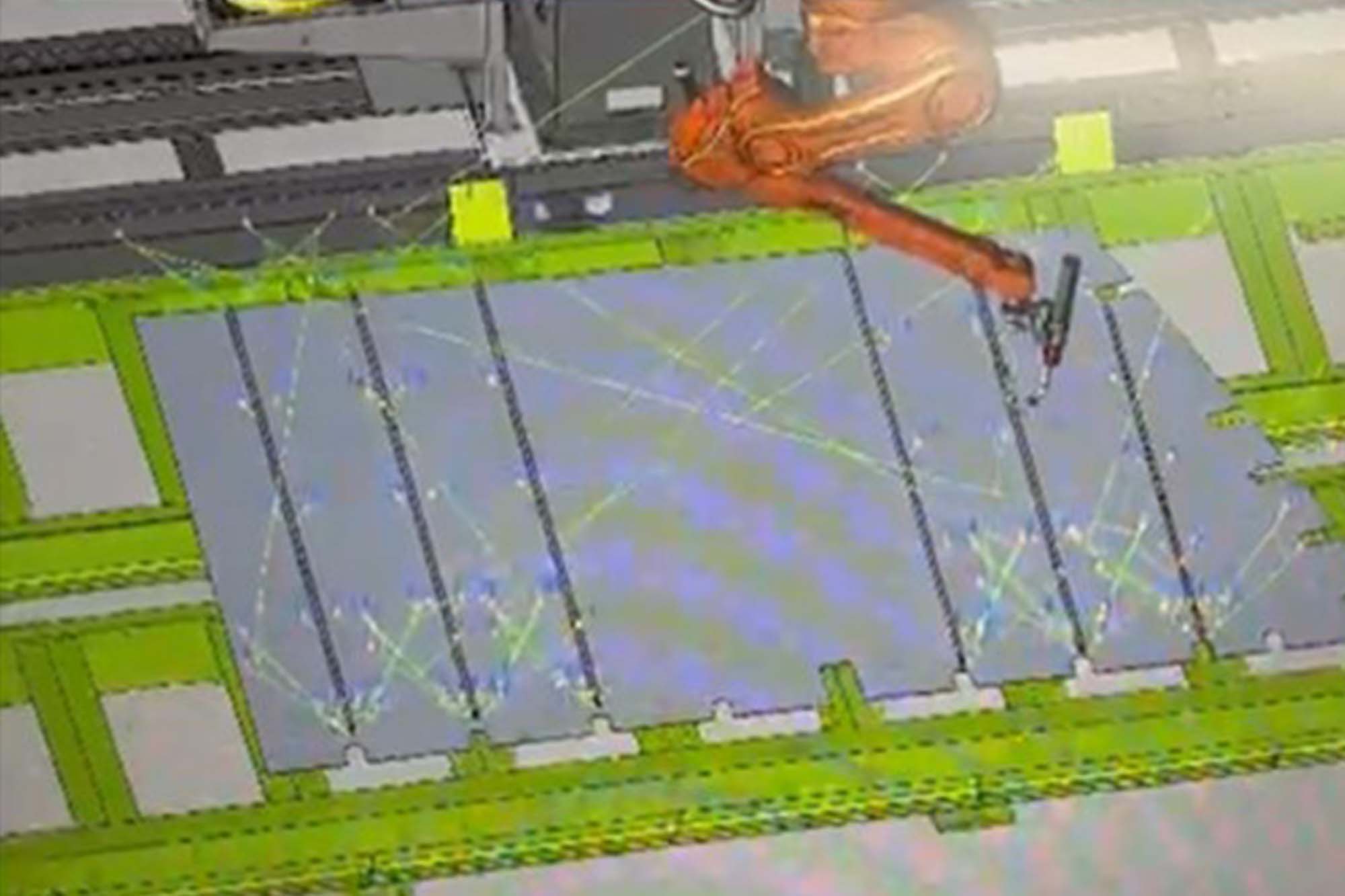

CLOOS ROBOPLAN- Offline programming during production: Increase the degree of system utilisation

While the system is in production, a new program can be simultaneously produced in RoboPlan. The welding, search and travel paths and tools can be determined using 3D models, and the welding parameters and other functions required for running the program can then be defined. The program is developed this way before being transferred to the robot controller for optimisation in the workplace. This process is less time-consuming than producing a whole new programme in the system.

Cloos India Welding Technology Private Limited

Plot No. A 39, H – Block, M I D C Pimpri,

Pimpri Chinchwad, Pune, Maharashtra – 411018

Website:- www.cloos.de

Email :- contact@cloos.in ,

Mobile:-7003545907 / 9168383939

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.