Flexibility in manufacturing with automatic gripper changes

By Staff Report February 19, 2025 6:23 pm IST

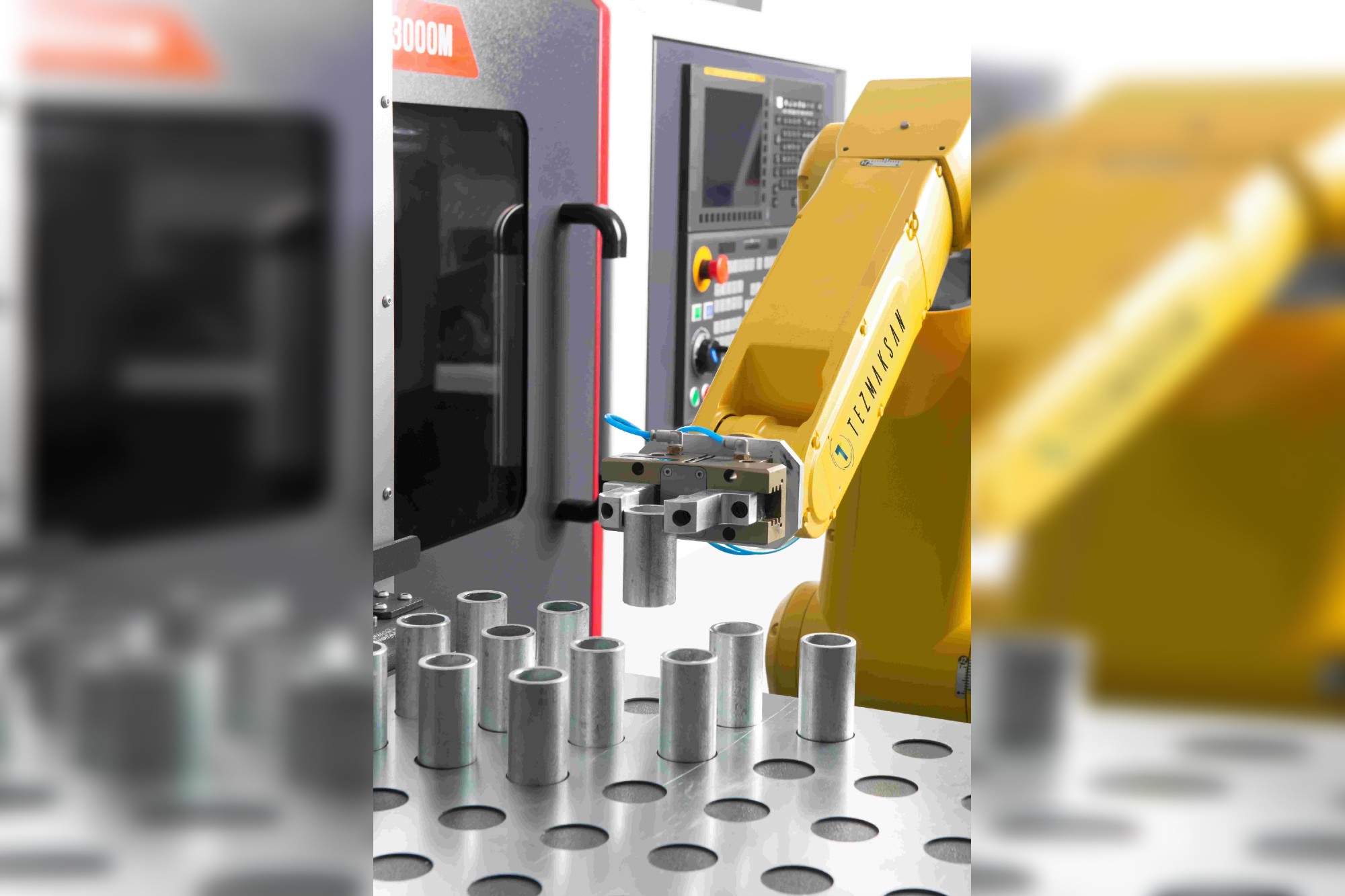

Production manufacturing demands are increasingly diverse, meaning that adaptability and efficiency are essential. Automatic gripper changes provide a practical solution for CNC machines to transition seamlessly between tasks without manual intervention. Here, Hakan Aydogdu, CEO of CNC automation system manufacturer Tezmaksan Robot Technologies, explains how by leveraging automatic gripper changes, manufacturers can optimise CNC machining operations.

Traditional CNC setups often require manual adjustments when switching between different workpieces. These manual interventions not only consume valuable time but also increase the risk of errors, leading to production bottlenecks.

Similar to a traffic jam, bottlenecks are often a localised issue that cause widespread disruption. In industries that depend on varied production runs or customised orders, such delays can disrupt schedules and escalate costs.

Automatic gripper changes address these challenges by allowing CNC machines to adapt seamlessly to different tasks. By automating transitions, manufacturers can maintain a steady workflow and meet demanding delivery schedules.

High-mix, low-volume production made easier

High-mix, low-volume production environments — characterised by frequent customisations and small batch sizes — rely on quick adaptability to remain competitive. Automatic gripper changes allow CNC machines to handle varying workpieces efficiently without interrupting workflows. This flexibility lets manufacturers meet diverse customer requirements without compromising throughput.

Consistency in positioning and repeatability are critical for producing high-quality components. In industries like aerospace and automotive, even minor deviations can have significant consequences. Manual adjustments during production can introduce variability but automatic gripper changes ensure accurate and repeatable transitions. This leads to higher quality outputs and fewer defects.

Moving forward with automation technologiesThe integration of automation technologies such as automatic gripper changes aligns with the broader goals of Industry 5.0 — combining digitalisation with human-centric production strategies. By adopting these solutions, manufacturers can achieve greater efficiency, precision and adaptability while empowering their workforce with intuitive tools.

Retrofitting existing CNC machines with automation capabilities is a practical solution for small to medium-sized enterprises (SMEs) looking to modernise without incurring the high costs of new equipment. Hardware-agnostic solutions allow manufacturers to enhance their legacy machines’ functionality, extending their operational lifespan and delaying the need for costly replacements.

Modern automation systems are designed for ease of integration. Their plug-and-play design simplifies adoption, making it feasible for SMEs to incrementally upgrade their production capabilities. This approach bridges the gap between current operations and the demands of a more digitalised manufacturing environment.

Tezmaksan’s CubeBOX CNC automation systems integrate automatic gripper changes into CNC workflows, enabling machines to transition between tasks effortlessly. This innovation is particularly beneficial for manufacturers balancing diverse production requirements with the need for high throughput and tight delivery schedules.

By incorporating automatic gripper changes, the CubeBOX system allows manufacturers to perform multiple machining tasks within a single setup. This minimises manual intervention, reduces errors and ensures consistent quality across production runs.

Furthermore, the CubeBOX system’s modular design and compatibility with various CNC machines make it an accessible and cost-effective solution for modernising operations.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.