How EMS 4.0 support energy management in manufacturing

By Staff Report February 7, 2025 7:16 pm IST

Following the dramatic rise in electricity prices, energy consumption is becoming an increasingly important variable that needs to be carefully influenced. Energy management systems have long offered a solution. But now there is an IIoT-supported application for capturing and optimising energy consumption, which promises considerable added value as in many other digitalisation areas.

For decades, energy costs were a reliable and predictable variable in production. They were easy enough to calculate with around 5 cents per kWh competitive costs. There are several reasons this calculation is no longer reliable; the war in Ukraine and the energy transition prompted by climate change are perhaps the most significant. Organisations should now budget around 25 cents per kWh, meaning that energy costs have a much greater impact on production costs and energy-intensive companies, in particular, face major problems.

Most importantly, there is no improvement in sight; quite the opposite. CO2 pricing will cause energy costs to climb higher, and the urgent need to renew and expand electricity grids will mean that electricity costs will need to be passed on to users.

Managing energy – a task for today and tomorrow

What is scarce, expensive, and essential needs to be ‘managed’, which is why energy management is the current watchword. Appropriate IT tools are available and frequently used. These use energy meters to capture consumption (for electricity, gas, compressed air, etc.), which users can then trace to individual production areas, systems, or even production quantities.

These systems are useful when fully integrated into the organisation’s or production department’s data environment and not operated as stand-alone devices. This way, the ‘adjustment screws’ for targeted optimisation and clear allocation of energy costs to individual products or production steps will be transparent (in the best-case scenario).

EMS 4.0: comprehensive database for optimising energy consumption

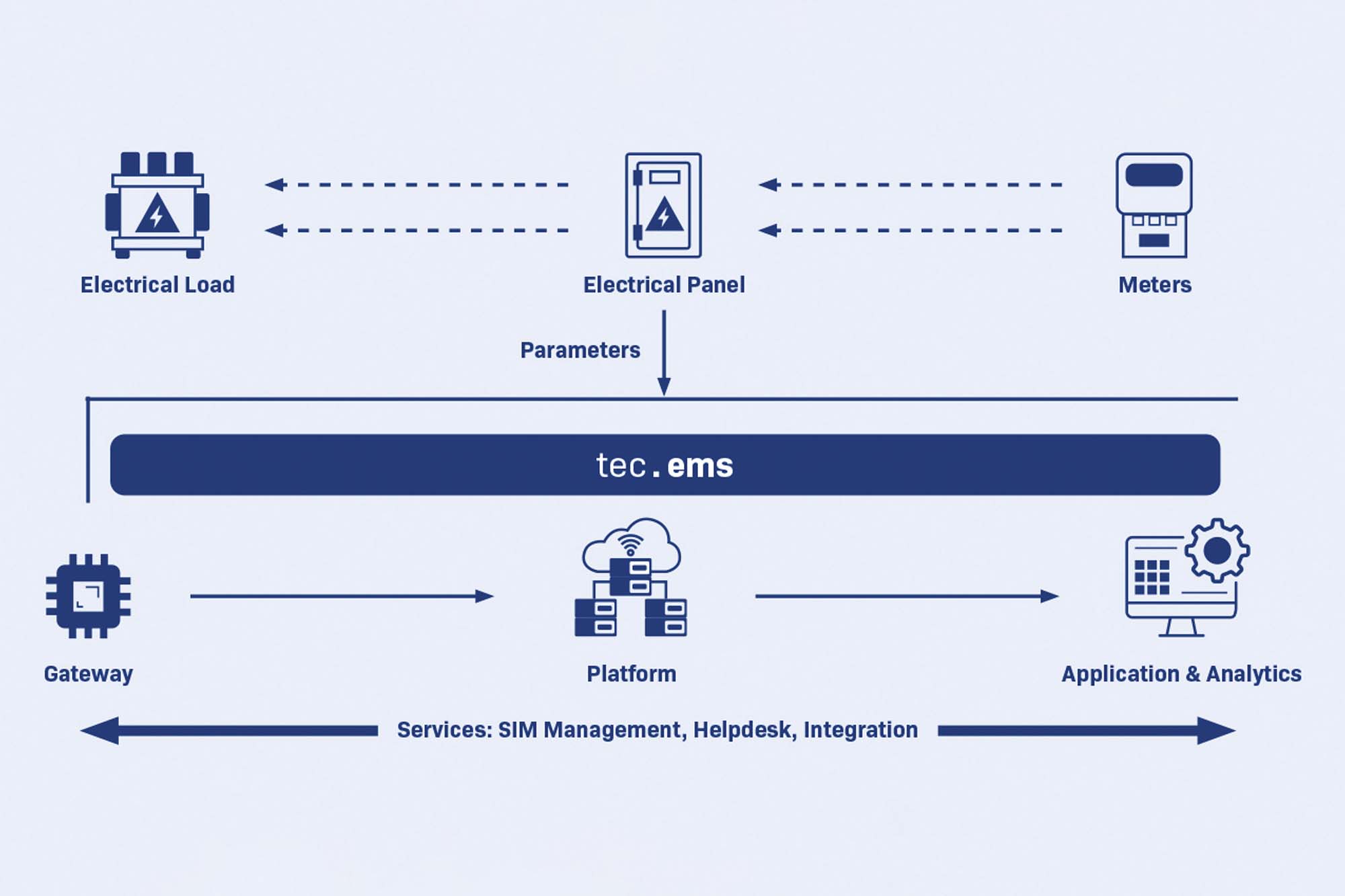

tec.nicum, the Schmersal Group’s newly established service division (see text box), has developed a modular solution in the form of the ‘Energy Management Solution 4.0’ or EMS. It is part of a comprehensive IIoT platform whose task is to bring transparency to production and provide users with a comprehensive database for far more than just energy consumption.

As a plug-and-play module within this solution, EMS 4.0 makes it easy to set up and assign energy meters. A dashboard visualises the consumption of all systems and their development. A range of evaluation functions generates detailed reports on energy consumption, including individually defined parameters. Limit values can be defined, and an (alarm) message can be emitted if these values are exceeded.

This provides users with a solid basis for energy efficiency initiatives, allowing them to test and evaluate the efficacy of individual measures and prepare the data for CSR reporting, which is already compulsory for larger companies across the EU. This requirement will gradually be rolled out to smaller companies.

(Fig. 2: Energy consumption is accurately captured and broken down into constituent elements.)

Energy efficiency as a KPI factor

EMS 4.0 differs from other energy management systems in integrating into the comprehensive IIoT concept developed by the Schmersal Group, which it makes available to its customers as a platform. This IIoT platform was essentially developed for the task of ‘Safety as a Service’ and for IIoT-supported service concepts (condition monitoring and predictive maintenance), but as it captures and analyses wide-ranging (production) data, it is also suitable as a basis for energy management.

Task: to capture overall equipment effectiveness (OEE)

And because calculating KPIs is also part of the IIoT concept developed by tec.nicum (as are condition monitoring and predictive maintenance), energy efficiency can be related to KPI-relevant data. More specifically, as the IIoT platform captures central KPIs for production, energy-related data may be incorporated into these KPIs, which applies to the overall equipment effectiveness (OEE) KPI. It captures the productivity and effectiveness of a production system, thereby allowing systems (in the same or different production facilities of an organisation) to be compared, as well as targeted optimisation of this KPI.

First usage example: production of household appliances

The first user of Schmersal’s ‘Energy Management Solution 4.0’ is using exactly this option. Plant management at the Indian production facility of a global manufacturer of household appliances had set itself the goal of increasing energy efficiency in production year on year, with a 2% to 5% reduction in energy consumption about production volume each year – and a matching positive impact on the carbon emissions from the site (which are also accurately recorded).

The company was looking for a comprehensive, IT-supported solution to bring transparency to the current status, while also allowing KPIs such as OEE to be captured. The third requirement was for the database to document progress – in part for international ESG reporting.

(Fig. 3: Electricity meters’ most important parameters are captured and forwarded for further processing. EDGE gateways collect the data of all parameters forwarded to the platform. The data are stored and processed on the Schmersal IIoT platform and forwarded to the EMS 4.0.)

The site’s managers approached the Schmersal Group’s IIoT Global Competence Centre, which is also based in India, with their list of requirements. The Competence Centre was already planning the market launch of the ‘Energy Management Solution 4.0’ and was able to use the manufacturer as an initial ‘use case’.

Hardware: failsafe edge solution

When selecting hardware components, particular care was taken to ensure that components can maintain communication with the web server for a defined time, even if there is a power failure. The data captured from machinery and drive systems and recorded by energy meters and other sensors is initially collected at the edge level, i.e., near production, and analysed in real time. 4G Modbus IoT gateways are just one of the devices used for this.

This means that users can access almost all current data at all times, which can also be used directly to control the energy supply and generation (solar systems, generators, etc.). Parallel to this, comprehensive reports are also generated to document the progress made in reducing energy consumption and carbon emissions.

The benefits of digitalisation – fusing energy and production data

The household appliance manufacturer is satisfied with this solution: the personnel effort required to capture and analyse energy consumption has been drastically reduced and the OEE key figure has improved substantially. Operational safety has also been improved with close monitoring of critical energy consumers and generators. The same also applies to energy distribution systems. Irregularities are largely identified in real-time and reported immediately, e.g. by SMS text message, to the person responsible.

Transparency even goes so far as to capture the energy consumed by each product manufactured – that is to say individually- for every household appliance that comes off the production line. To ensure this, the energy data must be related to the production data of the digital plant. Schmersal’s IIoT platform also ensures this.

(Fig. 4: The ‘Energy Management Solution 4.0’ is part of a comprehensive IIoT platform whose task is to bring transparency to production and provide users with a comprehensive database for far more than just energy consumption.)

————————————————————

NEW RESPONSIBILITIES FOR TEC.NICUM: ENERGY MANAGEMENT AND ‘SAFETY AS A SERVICE’

The Schmersal Group recently restructured its service, consulting, and engineering offerings and bundled them into an independent company: tec.nicum—Solution & Services GmbH. The division operates worldwide and currently employs 162 people, most of whom are technicians and certified functional safety engineers.

More important than the new structure is the significantly expanded range of services, covering digitalisation and software. In this area, tec.nicum offers new solutions that include a tool for carrying out risk assessments, as well as new digital services such as cloud solutions, IIoT applications, and energy management tools.

The ‘backbones’ of these services include a stable IIoT platform that ensures reliable communication between all participants (from sensors and display systems to gateways, servers and the cloud). This tec.nicum-developed platform has proven its value in the IIoT-supported energy management system and other applications. tec.nicum experts are already working on the next step, which will see safety data collected, transmitted and analysed by the platform. This creates the conditions for fully new, comprehensive services, a new business model and ‘Safety as a Service’.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.