Schmalz unveils cutting-edge solutions for efficiency, safety, and ergonomics

By Staff Report January 13, 2025 6:53 pm IST

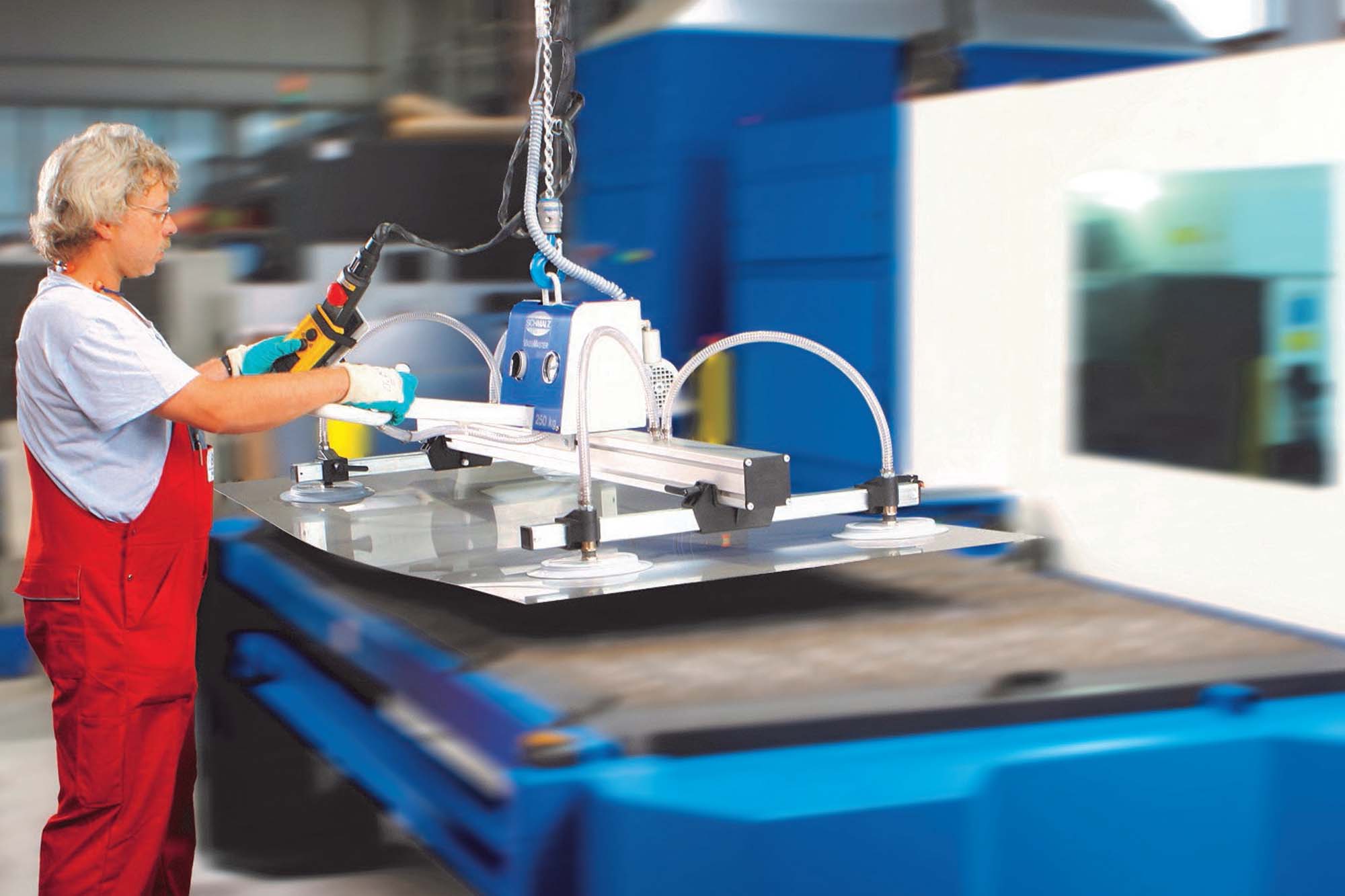

Material handling is a critical aspect of machine tool manufacturing, where precision, efficiency, and safety are key. Workers often face the physical demands of lifting, moving, and positioning heavy materials, leading to fatigue, injury, and decreased productivity. With Schmalz’s advanced material handling systems, this process is streamlined, turning a traditionally challenging task into a seamless, efficient, and ergonomic operation.

Schmalz revolutionises material handling with its ground-breaking solutions, including the VacuMaster, Jumbo Vacuum Tube Lifters, aluminium crane systems, jib cranes, and chain hoists. These innovative products are more than tools; they are game changers that empower operators to handle loads that once required multiple hands, significantly enhancing productivity while protecting worker health.

Schmalz’s Jumbo Vacuum Tube Lifters are highly efficient tools designed to optimise material handling operations across various industries. With models tailored for different lifting capacities, these lifters streamline processes involving frequent, fast, and ergonomic handling of materials. For example, the JumboFlex is ideal for smaller loads of up to 50 kg, making it suitable for internal logistics involving compact items like cardboard boxes, bags, and barrels. In contrast, the JumboErgo and JumboSprint models can handle heavier materials up to 300 kg, such as wooden boards, solar panels, and rubber bales, making them indispensable in CNC machining and food processing. These lifters ensure a smooth flow of materials, reducing handling and loading times, and promoting safe, damage-free lifting. By incorporating ergonomic designs and intuitive controls, the Jumbo lifters help reduce employee strain, improve motivation, and decrease the risk of work-related musculoskeletal injuries, making them a smart investment for companies focused on efficiency and employee well-being.

The VacuMaster series adds even more power to material handling tasks, with capacities ranging from 250 kg to 2,000 kg, depending on the model. The VacuMaster Basic and Comfort models are particularly suited for handling large, flat, and mostly airtight workpieces such as metal sheets and wooden boards, with a lift capacity of up to 750 kg. Their ergonomic design ensures minimal physical strain, while builtin safety features, such as a vacuum reservoir and warning devices, offer secure operation. For even heavier tasks, the VacuMaster Vario model provides horizontal handling for workpieces weighing up to 2,000 kg, making it indispensable for large-scale operations, including rotor blades up to 60 meters in length. These devices reduce the risk of damage to goods and increase workflow efficiency, offering unique features like controlled vacuum generators for energy savings.

Complementing the vacuum lifters are Schmalz’s aluminium crane systems and jib cranes, designed to enhance material handling capabilities. These systems are lightweight yet robust, enabling efficient handling of heavy loads with minimal effort. Their innovative design allows easy integration into existing work environments, whether as standalone solutions or as part of a more extensive material handling setup. The aluminium crane systems significantly reduce the effort required for lifting tasks—users can save over 60% of the physical force typically needed when using conventional steel cranes. This decrease in effort reduces fatigue and health-related absences among workers, promoting a safer and more productive workplace. The modular nature of these systems allows for tailored configurations to meet specific operational needs, ensuring optimal functionality.

In conjunction with the crane systems, Schmalz Chain Hoists is engineered for reliable and powerful performance in industrial settings. Capable of lifting loads to 2,500 kg, these chain hoists are particularly effective when paired with VacuMaster lifting devices. The hoists feature a robust design with a low-maintenance motor, ensuring longevity and dependability even in challenging conditions. Safety is paramount; the chain hoists include standard features such as a double slip clutch for overload protection and a limit switch for enhanced operational safety. The plug-andplay connectors enable quick installation, while the optional frequency control allows for sensitive load positioning.

By integrating aluminium crane systems, jib cranes, and chain hoists with the VacuMaster series and Jumbo Vacuum Tube Lifters, organisations can streamline their material handling processes, achieving greater efficiency and safety in their operations. This holistic approach to lifting and handling solutions positions Schmalz as a leader in the industry, providing the tools necessary for effective and ergonomic material handling.

ContactSchmalz India Private Limited

Marketing Department

EL 38, J Block, MIDC, Bhosari, Pune 411026

T: 020-69115500

marketing@schmalz.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.