Kistler Instruments brings the R & D backed automotive testing and industrial precision

By Staff Report January 13, 2025 6:13 pm IST

Kistler Instruments, a global leader in dynamic measurement technology, drives innovation in automotive and industrial automation with cutting-edge sensors, inline monitoring systems, and Industry 4.0 solutions. Operating in India since 2010, they prioritise R&D and customer-focused advancements.

Kistler Instruments is a more than 60-year-old global leader in dynamic measurement technology for measuring pressure, force, torque, and acceleration. Kistler products can be used to measure processes on the frontiers of physics. Their solutions facilitate the analysis of physical processes, control industrial operations, and deliver valuable information to optimise product quality. The knowledge gained often prompts customers to develop innovations, strengthening their competitive edge.

The vision of Industry 4.0 is already becoming a successful reality in numerous industrial applications nowadays – automobile manufacturing, medical technology and electrical engineering. Unprecedented optimisation of all production processes is possible due to increased digitisation and machine and system networking growth. Consistent control of the production chain – with zero-defect production is the goal, and any modern production business needs to hold its value in the market. A few years ago, virtually all products were still being inspected offline after manufacturing. Nowadays, products are monitored during production or ‘inline’ to avoid unnecessary costs.

Kistler Instruments shifted from component manufacturing to being a solution provider, with multiple solutions available for multiple industries. Their next step is digital forays and consulting businesses. Kistler is also investing 30 per cent of its turnover in R&D activities in preparing the next generation of products.

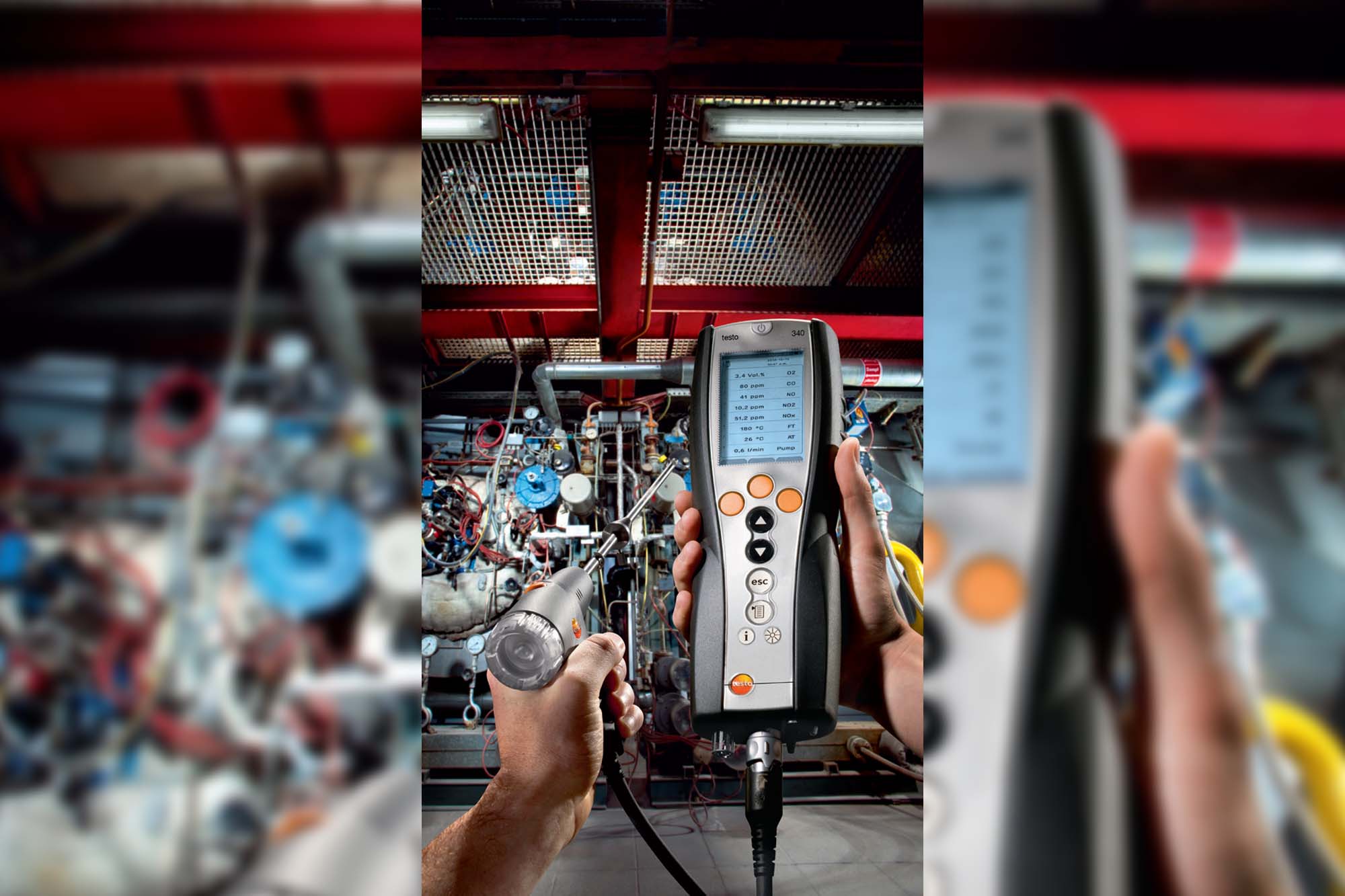

On the automotive side, Kistler Instruments has products for engine R&D and for the development of new engines; they have pressure sensors and combustion analysers with the software that goes along with it to provide a complete end-to-end solution. All the major automotive industries use these solutions to develop new engines on test beds. Kistler also has solutions for complete crash testing, wheel force measurement, and noise and vibration analysis that reinforce the measurement and testing of the vehicles, covering a range of vehicle testing solutions.

Along with T&M products, Kistler has electronics and the software that goes with the sensors for a complete measurement solution for the industry – test stands for Electric Motors, COF measurements of Fasteners, Servo Spindles and XY monitoring devices for Assembly lines. Kistler has a calibration lab in India to support the calibration of Instruments.

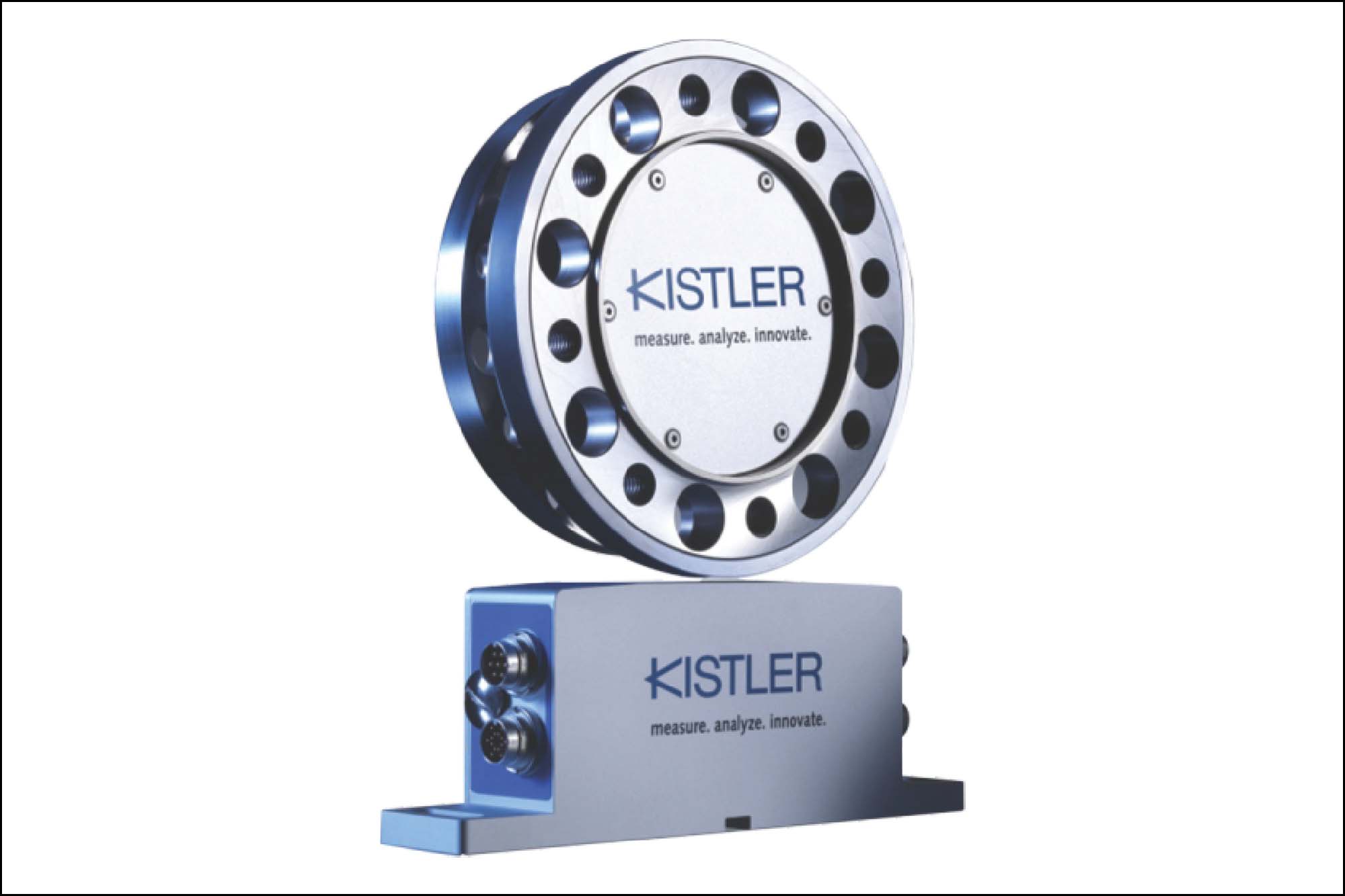

maXYmos system

In assembly technology, Kistler’s maXYmos system reliably monitors the production processes. The result: production can be optimised to achieve zero-defect production with maximum cost efficiency. The system’s outstanding features are its exceptional flexibility and user-friendly operating interface. It can be used for automated joining, press-fit processes and manual operations such as pressing processes carried out by hand. In addition to production and assembly, Kistler’s sensors and XY monitors can be used to verify to verify the end product’s functionality. Kistler’s XY monitors are quite versatile as they can meet the requirements in all industrial sectors where quality assurance is a prime consideration. The maXYmos TL detects defective parts or deviations early in production and displays them transparently. This leads to minimised downtimes, optimised test sequences, and improved plant availability. Thus, the integrated process control enables higher quality and lower costs in assembly and testing. Kistler has secured its reputation worldwide as a leading supplier of sensor systems by gradually expanding its product portfolio. The innovative maXYmos family stands out for its system uniformity and simple, intuitive operation, making it an integral part of modern industrial manufacturing processes.

When testing products, users can rely on an intuitive system designed for quick and accurate assessments. This system has capabilities such as force-displacement monitoring and torque monitoring, either over time or based on the angle of rotation. Equipped with a wide range of interfaces, it serves as an ideal platform for recording multiple parameters and facilitating their comprehensive evaluation.

The ‘Sequencer Mode’ is user-friendly. The test sequences can be programmed into the device and analysed online in real time. These sequences can easily be parameterised on the device and perform simple control tasks. System solutions for process-integrated quality assurance ensure that data captured by highly sensitive piezo sensors is effectively utilised by being visualised, evaluated, and documented through suitable monitoring systems. By integrating these measuring systems into the manufacturing sequence, production defects can be detected early, significantly reducing the risk of financial losses caused by faulty parts.

Customers in the industry benefit from Kistler’s extensive experience as a development partner, which enables them to optimise their products and processes, thereby securing a sustainable competitive edge. This Swiss corporation is important for advancing automobile production and industrial automation. Its innovative sensor technology also contributes to the growth of many newly emerging sectors. With a deep foundation of application expertise and an unwavering commitment to quality, Kistler continues to drive innovations in lightweight construction, vehicle safety, emission reduction, and Industry 4.0.

Kistler began direct operations in India in 2010 and has established offices in the North and West of Pune and Chennai. Their team consists of trained marketing and after-sales service specialists and engineers. Kistler supports various industries, including automotive, defence, education, and sports. They offer products tailored to meet the needs of these different sectors in the Indian market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.