TruCut ensures precision and efficiency in each tool batch

By Staff Report December 2, 2024 6:38 pm IST

TruCut Tools has developed advanced CNC systems for continuous improvement. Zuzer T Lokat, Director of TruCut Precision Tools Pvt Ltd how seeking customer feedback helps them deliver high-performance tools and develops trust with their clients.

What technologies ensure the superior performance of your solid carbide and HSS-Co rotating tools?

The latest CNC control systems offer superior control over machining processes, enabling precise and complex operations with ease. These machines deliver faster machining times and improved efficiency.

TruCut application engineers are actively involved in continuous improvement initiatives. Highly trained technicians and operators oversee the manufacturing process, ensuring that each tool batch is produced with precision and efficiency. Welltrained quality inspectors monitor every production stage, conducting inspections and tests to verify compliance with specifications and standards.

What emerging technologies is Trucut Tool exploring to enhance tool performance?

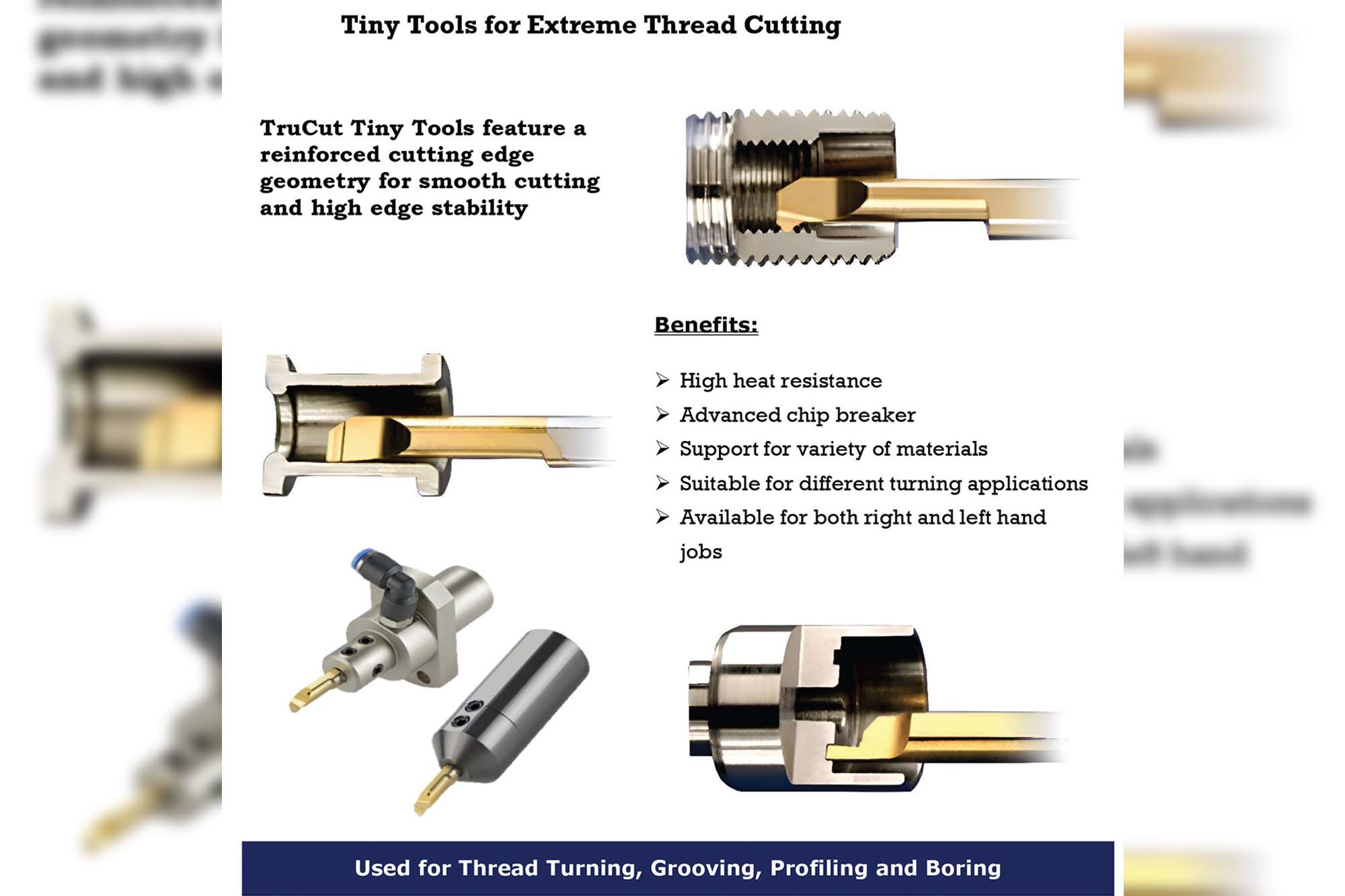

TruCut focuses on technological advancements and industry trends, making us the ideal partner for developing primary and secondary aircraft components. We offer the most comprehensive range of solid carbide tools for metal and composite materials worldwide from a single source. Our flexible machining solutions for the aerospace industry set new standards for the highest productivity and process reliability, backed by exceptional technical support.

How does TruCut Tools ensure customer satisfaction and maintain a competitive edge in the machining industry?

Building a winning strategy requires paying close attention to customer feedback. Incorporating customer feedback into sales is a complex process that must be precisely executed. We use the right tools and techniques to collect, analyse, and effectively use feedback. We continually learn to leverage customer feedback to increase revenue and enhance customer satisfaction.

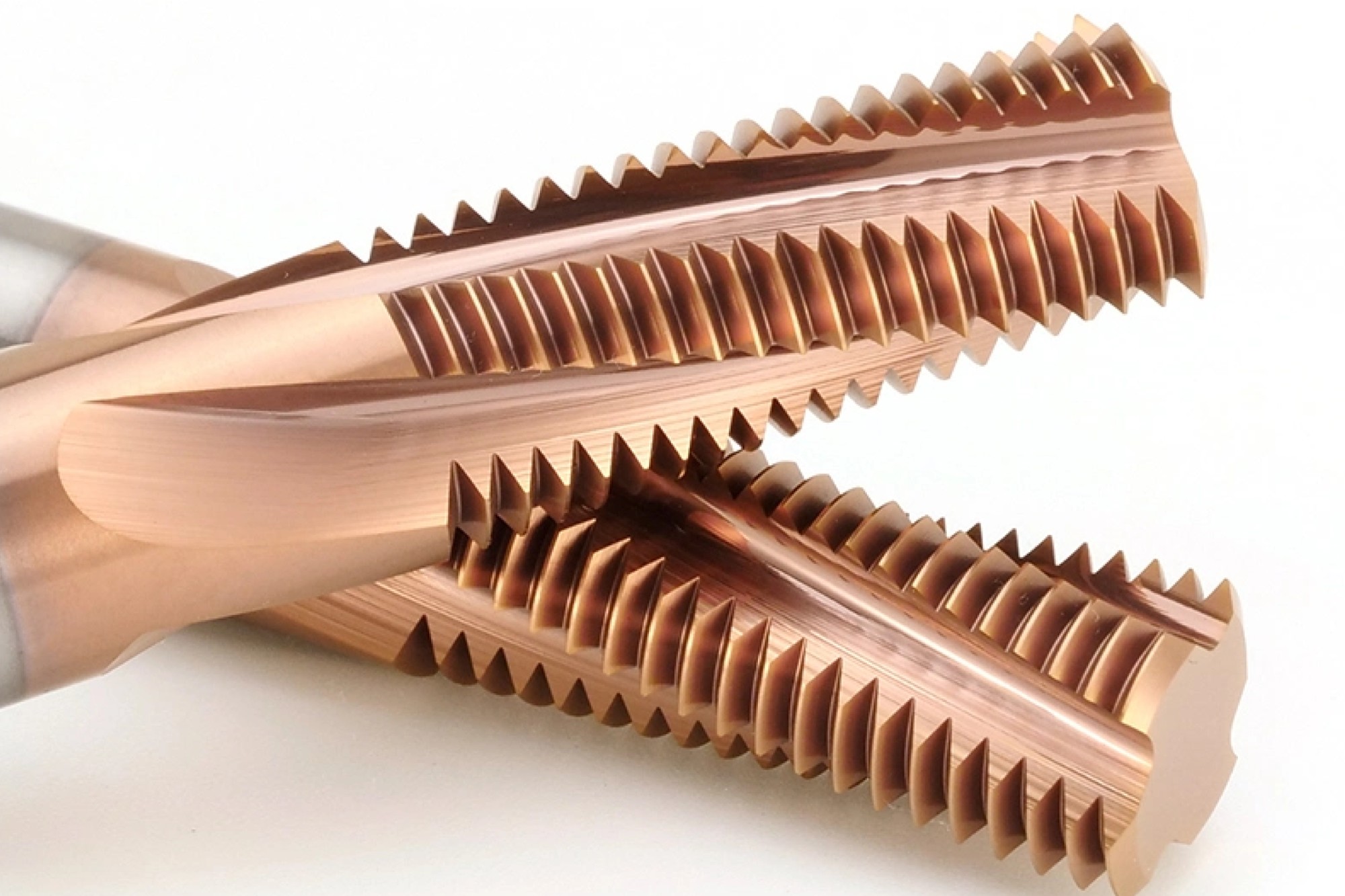

TruCut Tools ensures the machining world operates smoothly by providing quality, consistency, and timely delivery. With an extensive inventory of catalogue items ready to ship the same day and custom tools available with minimal lead times, we efficiently meet machining needs. The quality of our products is evident through optimised carbide quality, superior grinding techniques, innovative tool geometries, and advanced tool coatings. Each tool undergoes rigorous inspection and quality control to ensure consistency and peak performance. Our tools meet the highest standards in industries where precision and reliability are critical.What strategies do you employ to build and maintain long-term relationships with key clients in various sectors?

To build strong, long-lasting client relationships, our clients must trust and rely on us as experts in our field. By nurturing these relationships with key clients, we earn their trust and create opportunities for re-engagement, ultimately helping them save time and money. Our responsibility is to share information that helps clients understand our process, which builds trust and confidence. Feedback allows our clients to share their opinions on how we delivered our services and suggest improvements, helping us strengthen relationships with both current and future clients.

We aim to understand our clients on both a micro and macro level to ensure success. On the micro level, we focus on the specific goals and objectives of the product, while on the macro level, we consider how the project fits into the broader organisational context. By understanding our client’s goals, we build trust, foster mutual respect, and strengthen our relationships.

What future trends do you foresee in the cutting tool manufacturing industry, and how is your company preparing to meet these trends?

As new materials with superior properties are developed, we are adapting to work with these advanced materials and expanding our range of applications. Evolving technologies will undoubtedly play a key role in shaping the future of advanced manufacturing.

How do you ensure your production processes stay ahead of industry trends and technological advancements?

We emphasise technological advancements while staying aligned with industry trends. Continuous innovation and development are key drivers of our success. We have designed numerous high-performance tools and custommade solutions based on client specifications. As technology evolves and manufacturing processes become more sophisticated, the cutting tools industry is set for significant transformations. New grinding machines and technological advancements enable the creation of customised cutting tools, tailored to specific applications, enhancing both performance and efficiency.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.