ETA Launches Dynaform 7.2

By Staff Report November 11, 2024 6:16 pm IST

A game changer in sheet metal forming simulation software ETA’s Dynaform 7.2 introduces advanced features for sheet metal forming, enhancing precision, speed, and efficiency in die system processes for automotive, aerospace, and manufacturing industries.

Engineering Technology Associates, Inc. (ETA) launched Dynaform 7.2, the latest version of their leading sheet metal forming simulation software. Building on the capabilities of its predecessor, Dynaform 7.2 has a range of new features and enhancements designed to streamline and optimise the simulation of die system processes in the automotive, aerospace, and manufacturing sectors.

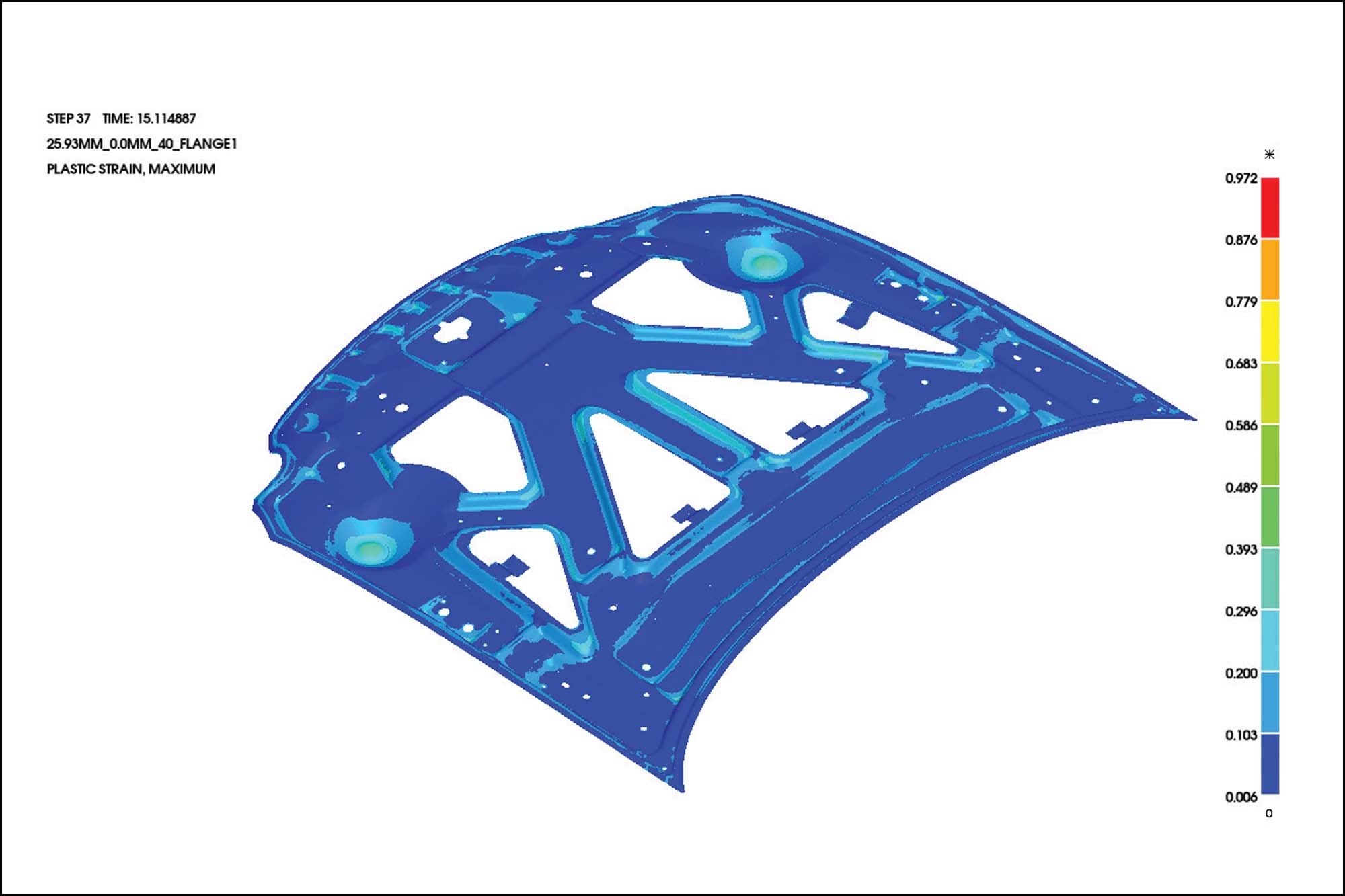

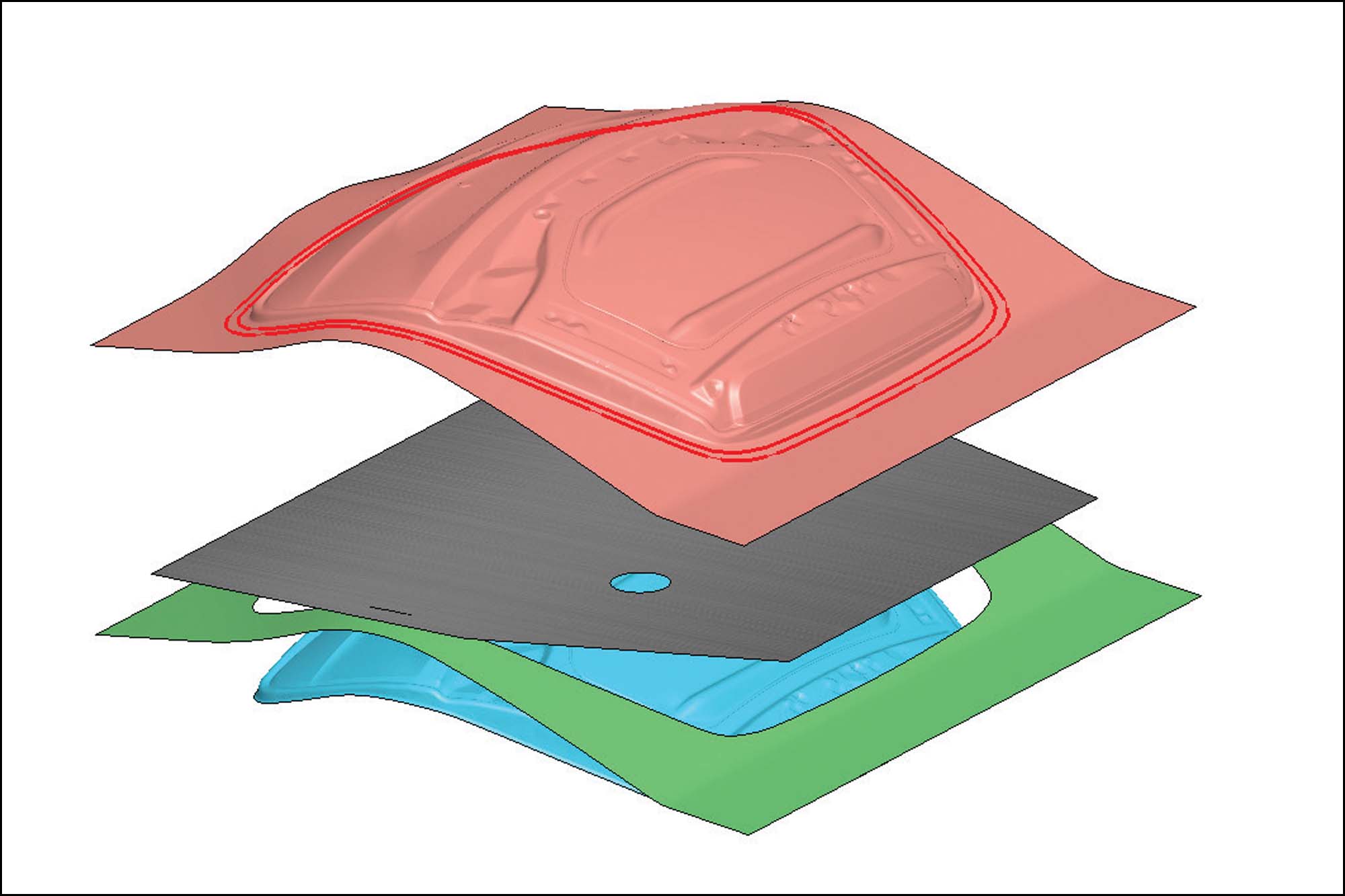

Dynaform 7.1 introduced advanced Die Face Design (DFD) and Formability Simulation (FS) capabilities. However, Dynaform 7.2 brings new features to improve the speed and precision of metal forming processes. Notable enhancements include improvements in Blank Size Engineering (BSE), Die Face Design (DFD), Formability Simulation (FS), and Tube Bending & Forming (TBF). The BSE module now offers better nesting results, providing users higher material utilisation rates. The DFD module sees a boost in tool design flexibility with features like the Auto CAM and Trim Segment functionalities, which streamline multistage design and cutting operations.

ETA’s Sigform solver is at the core of accurate and rapid multistage forming simulations to deliver more precise results under complex forming conditions. The Die Structural Integrity (DSI) module ensures dynamic analysis of die structures, offering detailed insights into mechanical performance, load-bearing capacity, and potential stress areas. “We’re thrilled to unveil Dynaform 7.2, a significant leap forward in sheet metal forming simulation technology,” said Dr Shan Nageswaran, CTO of ETA Inc.

Key Features of Dynaform 7.2Dynaform 7.2 introduces several critical new features, making it the most comprehensive sheet metal forming solution. Here are the key highlights:

- Sigform Solver Enhancements: Dynaform 7.2’s Sigform provides even greater accuracy and efficiency in sheet metal forming simulations, supported by parallel frameworks for faster processing.

- Die Face Design: A series of new tools, such as the Auto CAM, Trim Segment, and Flange Tool Enhancements, make multistage die face design easier and more intuitive. Users can trim, make flange modifications, and create addenda with increased flexibility.

- Clamping Springback in FS: This feature allows for the measurement of springback using pads, pilot pins, and clamps, enabling sequential closing for improved simulation accuracy.

- Hot Forming in FS: With the growing application of high-strength steel, Dynaform 7.2 introduces a user-friendly interface for complex hot forming setups, simulating various stages from gravity and forming to cooling and hardening.

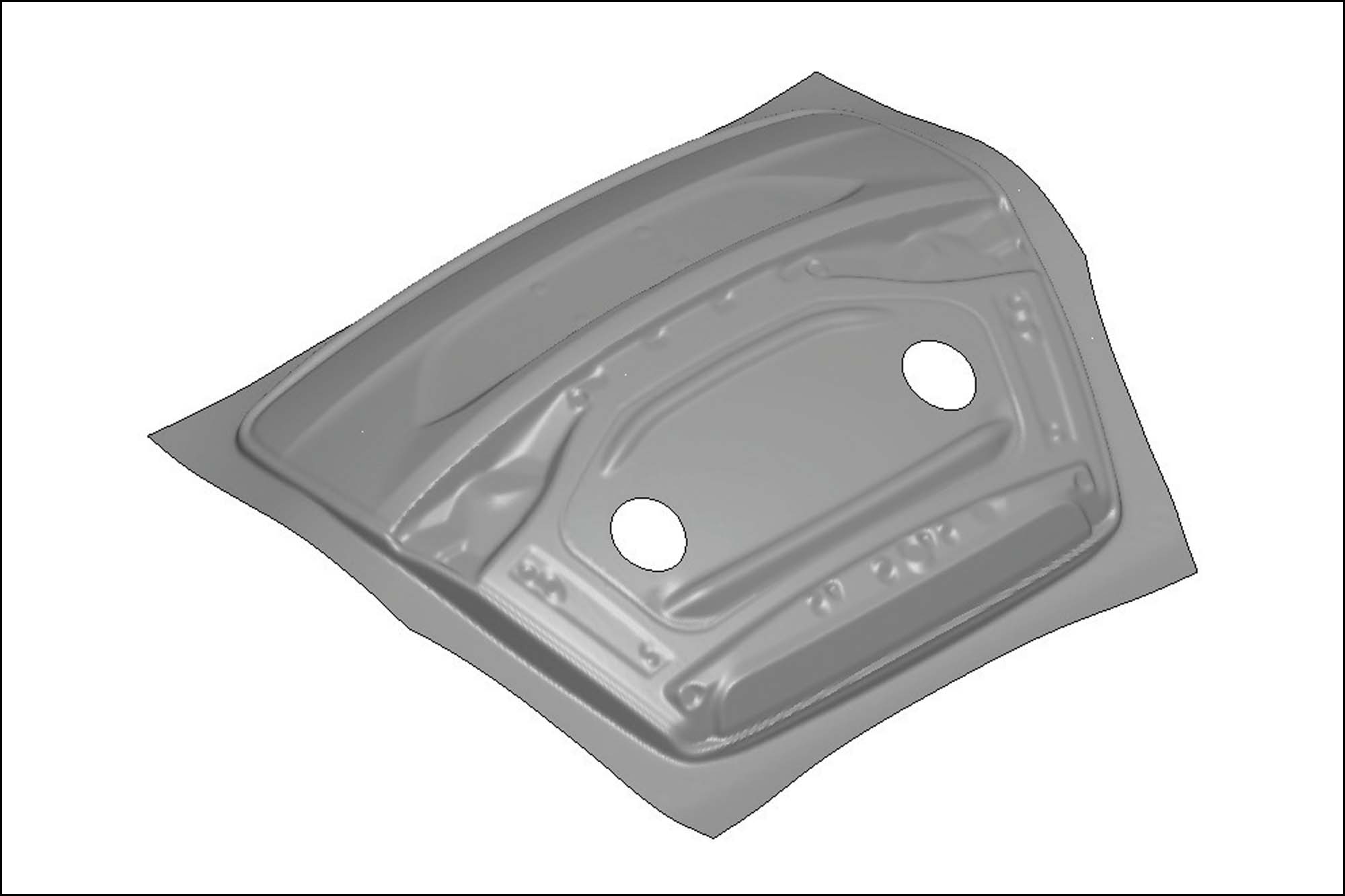

- Sheet Drop Test: Dynaform 7.2’s Drop Test module simulates part deformations during production, analysing issues like panel deformations from drops for dimensional accuracy in automotive components.

- Die Structural Integrity (DSI): This module offers insights into nonlinear, dynamic problems commonly encountered in mechanical and structural engineering.

With these advancements, Dynaform 7.2 offers a more integrated and efficient solution to the challenges of sheet metal forming for users to reduce production time, minimise errors, and increase profitability. This latest release can work to increase productivity and performance standards in the die-making process for automotive, aerospace, or other industrial applications.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.