Flying high lightly and safely

By Staff Report September 10, 2024 11:30 am IST

Engineered aluminium has proven to be a key element in developing lightweight, high-performing, and safe aircraft. It has improved aircraft performance and also led users to imply sustainability in their functioning.

Aluminium is a remarkable metal that has revolutionised numerous industries over the past century, benefiting the aviation industry the most. The lightweight and exceptional strength of aluminium makes it indispensable in ensuring that aeroplanes are safe, affordable, and feasible for transportation.

Aluminium has been a cornerstone of the aerospace industry since the Wright brothers’ first manned flight in 1903. They opted for aluminium to construct the cylinder block and other essential engine components, appreciating its lightweight and robust characteristics.

Since that historic flight, engineered aluminium’s role in aerospace has become fundamental in aircraft design and construction. Its exceptional properties have led to increased demand and numerous advancements in aviation technology.

Aluminium for the aircraft industry

Approximately 80 per cent of the metal content in contemporary aircraft is aluminium. The aerospace industry relies heavily on aluminium for two main reasons. Firstly, its high strength-to-weight ratio allows the construction of airframes that need to be strong and durable to endure the stresses of take-offs and landings. Secondly, aluminium’s lightweight nature reduces the fuel requirements during flights, making it cost-effective.

Engineered aluminium has outstanding corrosion resistance, a crucial factor in enhancing aircraft longevity. Planes are exposed to the elements and extreme conditions, such as freezing temperatures at high altitudes and various forms of precipitation, including snow and rain. Aluminium’s ability to resist environmental corrosion makes it an ideal material.

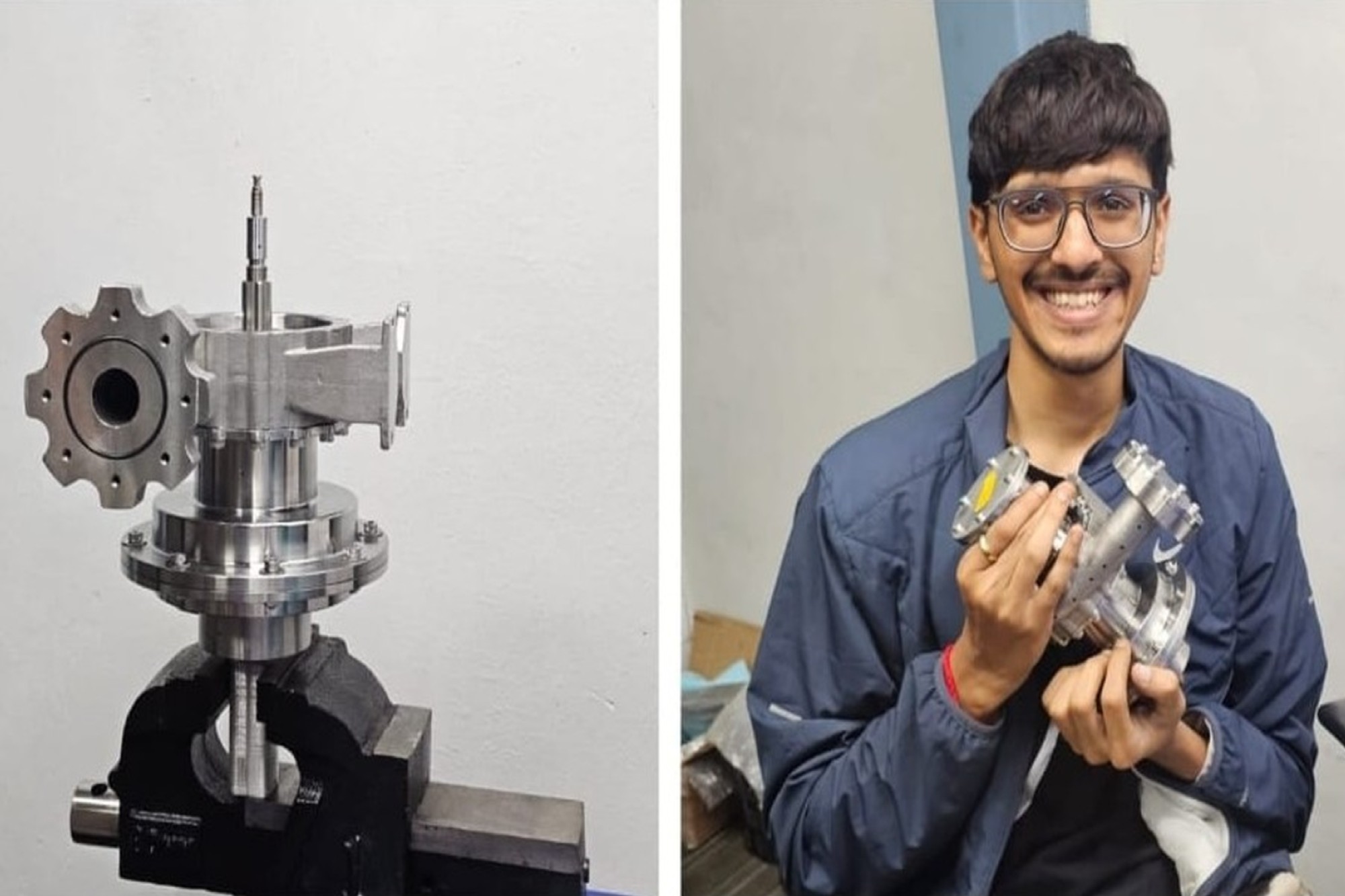

The aircraft industry demands precision for optimal aerodynamics and accommodating numerous small parts. The formable quality of aluminium makes it suited for this case. The ease of fabrication and machining of aluminium translates to cost savings compared to alternative materials. Furthermore, aluminium’s aesthetic appeal enhances the visual attractiveness of an aircraft.

Diverse Uses of Aluminium in Aircraft

Wings: Aluminium is used to construct the wing sections of aircraft and other aerial vehicles. This preference is due to its durability, lightweight properties, and ease of machining.

Aircraft Cabin Components: Components within the aircraft cabin, including tray tables, seats, and panels, are commonly crafted from engineered aluminium. Aluminium enhances the portability and longevity of these elements, ensuring durability and functionality throughout extended periods of use in aviation interiors.

Aircraft Fuselages and Components: Aluminium is utilised in constructing aircraft fuselages, prized for their robust strength, less weight, and corrosion resistance.

Fuel Tanks: Engineered aluminium is chosen for the production of fuel tanks in aircraft. Its corrosion-resistant properties promote the durability and safety of these components.

Key Aluminium Alloys Used in Aerospace

2024-T3: Alloy 2024-T3 is recognised as a high-strength aluminium alloy. While its corrosion resistance is slightly inferior to 6061, it excels in fatigue resistance. This alloy is utilised in manufacturing aircraft wing skins, fuselages, cowls, and structural components. Its polished surface makes it suitable for original construction and repair work in aviation.

5052 – H32: This non-heat treatable alloy is known for its exceptional strength within its category. Its formability and workability make it suitable for fabricating fuel tanks and other components requiring durability and resilience.

6061-T6: Grade 6061-T6 is distinguished by its durability and polished surface. It has superior weldability and demonstrates strength comparable to mild steel. Owing to its exceptional fabricability using standard techniques, this alloy finds extensive use in aerospace for constructing landing mats and other structural components.

3003-H14: Composed of pure aluminium alloyed with manganese, this non-heat treatable sheet can be easily deep drawn, welded, spun, or brazed. It is particularly favoured for crafting baffle plating and aircraft cowls due to its versatile manufacturing capabilities.

7075-T6: This aluminium alloy reinforces aircraft structures with its exceptional strength properties. Formulated with precise proportions of magnesium, copper, and zinc, it is engineered to provide enhanced strength and structural integrity. However, its copper content makes welding challenging, though not entirely prohibitive. Following anodisation, it exhibits a sleek finish and offers superior machinability.

The remarkable properties of engineered aluminium will shape the future of aerospace technology. Its lightweight and robust characteristics have already changed aircraft design and performance. With sustainability as a priority, aluminium’s recyclability and efficiency will help develop environmentally friendly aircraft. Moreover, advancements in aluminium alloy research and development promise to yield even lighter, stronger, and more resilient materials, setting the stage for continued innovation and progress in aviation engineering.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.