A fierce competitive world where top-notch quality will be an ultimate goal

By OEM Update Editorial July 16, 2024 1:39 pm IST

TruCut offers top-tier solid carbide and HSS-Co rotating tools backed by over two decades of expertise. Its commitment to quality serves both domestic and international markets, ensuring precision and performance.

TruCut has over two decades of experience in the cutting tool industry, with its primary mission to offer customers a one-stop shop for all their cutting tool needs.

One-stop shop for all cutting tool needs

TruCut is present in domestic and international markets, offering a diverse range of solid carbide and HSS-Co rotating tools. In a competitive industry, quality is the ultimate goal. This commitment to excellence is evident in every aspect of its production and service.

TruCut takes great pride and confidence in its ability to meet all requirements with its high-quality product line, ensuring that end users will appreciate using the products as much as it enjoys producing them. TruCut provides comprehensive application support and supplies to pan India. From its facility in Chennai and through its extensive dealer network, it offers top-notch carbide-cutting tools for various metalworking industries.

Manufacturing facilities

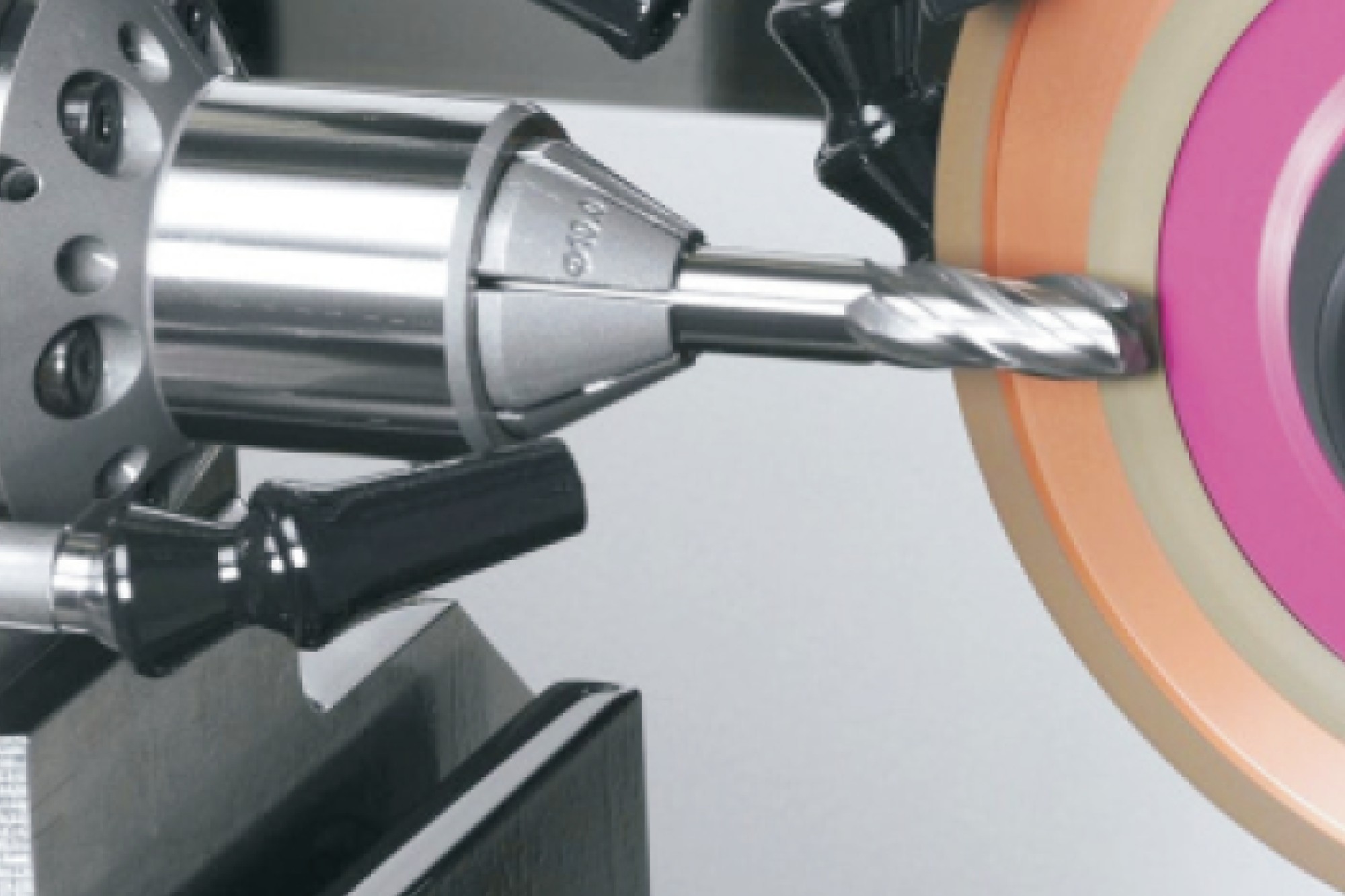

TruCut’s 15,000 sq. ft. production facility in Chennai has advanced CNC grinding and tool inspection machines. This facility ensures that every tool meets stringent quality standards, allowing customers to benefit from significant savings and increased productivity over time.

TruCut ensures consistent tool performance by installing advanced CNC 5-axis and 7-axis grinding Machines. Its Non-Contact 5-axis CMM Tool Inspection Machine guarantees precise geometry and dimensions, while laser marking provides permanent identification. Each tool is protected with high-quality single-piece packaging. TruCut maintains consistent quality and uses high-grade microfine and ultrafine carbide raw materials, along with HSS-Co imported from Europe. Additionally, our in-house forming section processes Unground carbide blanks.

Quality control measure

TruCut Tools ensures the machining world operates smoothly by providing quality, consistency, and timely delivery. With an extensive inventory of catalogue items ready to ship the same day and custom tools available with minimal lead times, it helps meet machining needs efficiently. The quality of products is evident through optimised carbide quality, superior grinding techniques, innovative tool geometries, and advanced tool coatings. Each tool produced undergoes rigorous inspection and quality control to ensure consistency and best performance. The tools meet the highest standards in industries where precision and reliability are critical.

TruCut invests in advanced tool production equipment, supported by state-of-the-art inspection machines and micro-level inspection procedures, to ensure that every tool meets the highest standards of accuracy.

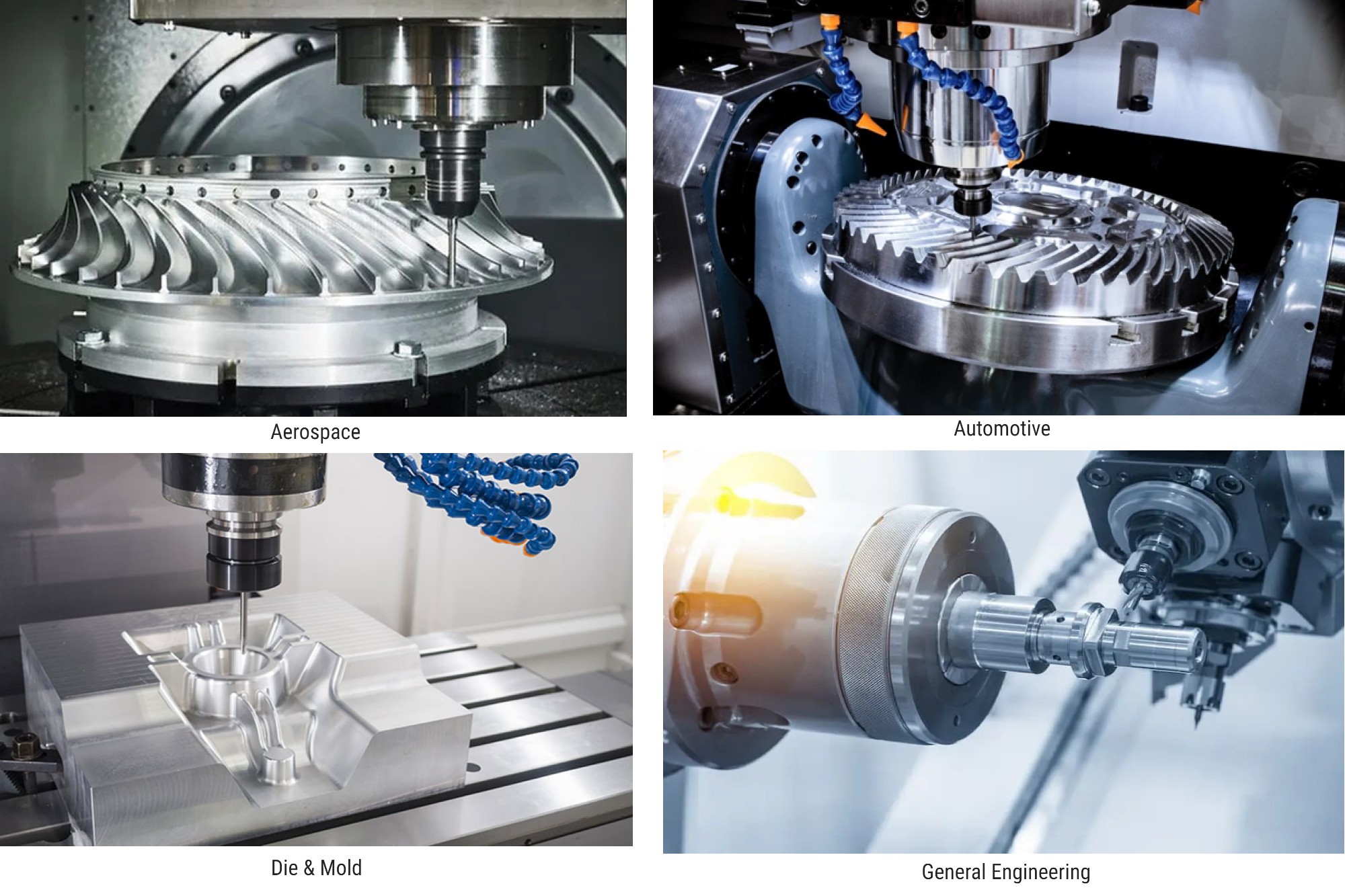

Industries TruCut serves

TruCut is the perfect partner for developing and producing primary and secondary Aircraft components. TruCut offers the most comprehensive range of solid carbide tools for metal and composite materials available for the aerospace industry, which sets new standards with the highest possible productivity and process reliability through technical support.

When machining automotive parts, achieving the highest production at the lowest possible cost is essential. TruCut fulfils this need and delivers on its promise to dramatically reduce long-term, prioritising quality and efficiency rather than selling cheap tools.

In the Die & Mold Industries, TruCut has been bundling decades of experience in Die and Mould tool making with a forward-looking product portfolio and designing individual manufacturing solutions with continuous process chains.

The General Engineering segment comprises job shops, contract manufacturers, electronic components producers, and others contributing to the manufacturing world. We provide innovative solutions that improve their regular processes and achieve an efficient output.

Industry-specific solutions

TruCut offers specialised solutions across various industries that are customised to meet the demands of each sector.

TruCut tools ensure the highest production rates at the lowest possible costs in the industry, promising to lower customers’ overall machining expenses. TruCut designs individual manufacturing solutions with continuous process chains to ensure efficiency and precision. Offering a broad range of solid carbide tools for super alloys and composite materials, TruCut provides flexible machining solutions that set new standards for productivity and process reliability.

TruCut adheres to its 5-TS (TruCut Standard) to ensure a high-quality and consistent product by:

- Appropriate Carbide Grade

- New Tool Geometry

- Precision Smooth Grinding

- Proven Inspection Procedure

- Advanced tool coatings.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.