Compressed air provisioning automotive manufacturing efficiency

By OEM Update Editorial July 12, 2024 12:20 pm IST

Compressed air in automobile manufacturing is a conscious selection process that leads to operational efficiency, safety, and quality across various applications. Thus, careful consideration of factors like air requirements, working pressure, and power efficiency requires a factorial decision.

Applications of compressed air in the automobile sector

Compressed air tools: Pneumatic Tools like power wrenches, air rachets, air rivets, air hammers, drills, sanders, and pneumatic nailing are all powered by compressed air systems. They are essential to the automotive assembly line due to their consistent performance, safety and compact design. They also generate sustained torque and speed without producing excessive heat or requiring complicated electrical systems.

Painting and body finish: A superior quality paint is expected to give a car a premium look. Compressed air is employed in spray painting applications to guarantee a flawless mirror surface and a consistent, dependable paint spray for door panels, side panels, roof pieces, and other auto body parts. Chicago Pneumatic Compressors offers a comprehensive solution for compressed air with add-on filters and refrigerated air dryers, which can reduce the compressed air temperature to a point where moisture condensation occurs. This can help remove moisture and minimise contaminants like dirt and oil within the air stream.

Laser, Plasma-Cutting and welding applications: Compressed air is used in laser and plasma-cutting processes for car manufacturing, where it acts as the primary or secondary gas to generate high-pressure and high-temperature plasma jets. Compressed air shields the weld in certain welding operations and improves weld seam quality.

Tyre inflation: Right from a petrol pump to a puncture shop, we all have seen a piston or a screw compressor used for inflating air in tyres to maintain sufficient pressure, ensuring a smooth drive.

Pneumatic Robotic assembly lines and material handling and holding: To boost the productivity of assembly lines, lean and flexible manufacturing and assembly systems are designed. These robotic assembly systems lift heavy auto parts and automobile body components via vertical lifts or conveyor systems. These automated systems are pneumatically operated and powered by compressed air systems.Factors for selecting a compressor for automobile manufacturing

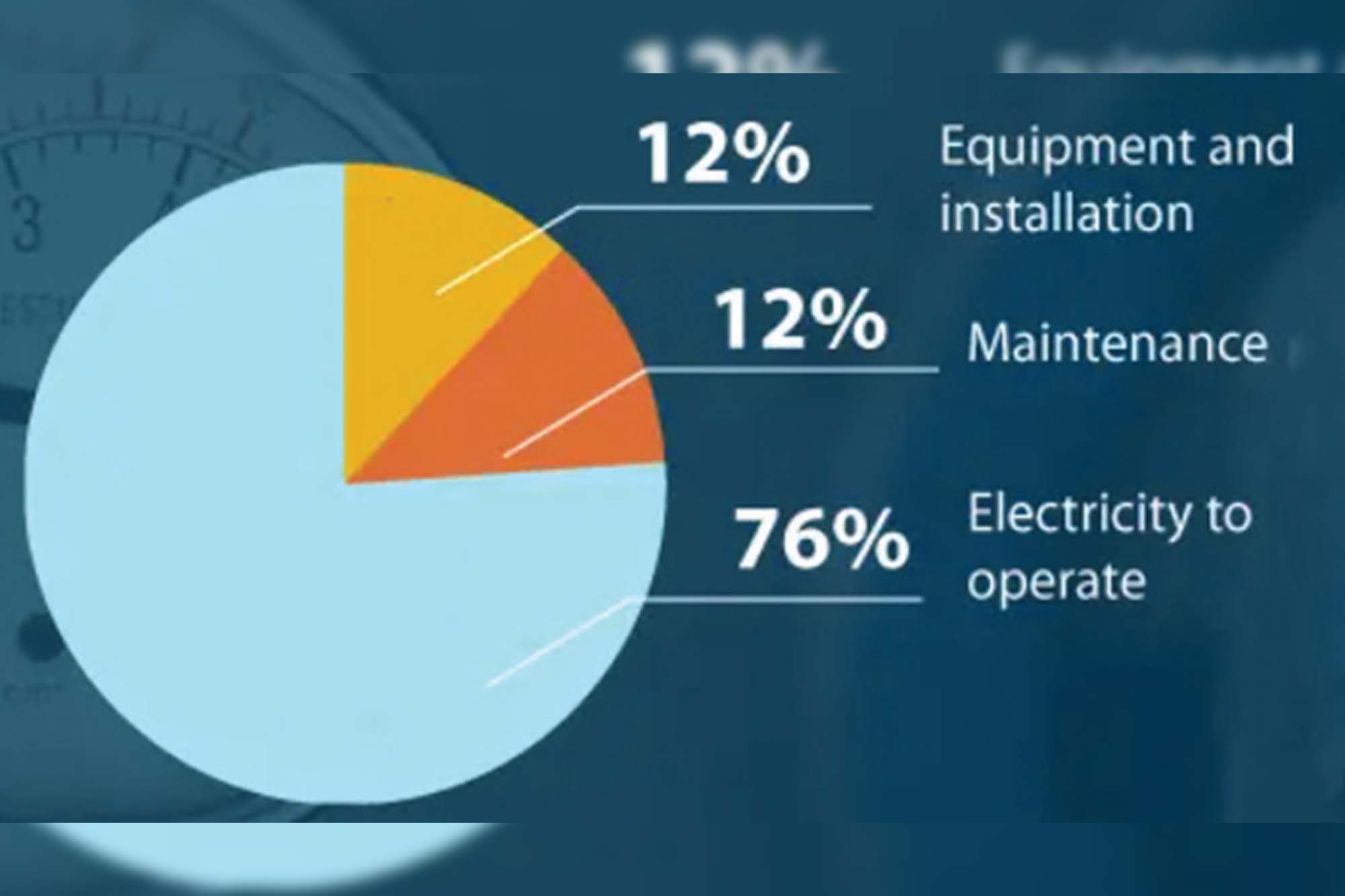

Compressors orbit almost every application in the world of automobile manufacturing. Selecting a compressed air solution requires some key considerations as it contributes to saving power, adding profits to business, leading to faster returns on investments, and reducing the carbon footprint for stepping towards a better, greener tomorrow.

Air Requirement: A compressed air installation should happen based on the required FAD(CFM), not compressor power. This is because, with every CFM, the power requirement increases, as does the capital and running cost. Load factor and simultaneous usage factor are important as all the machines are not loaded 100% and are not used simultaneously. Contact your nearest Chicago Pneumatic representative to learn your optimal air requirement.

Working Pressure: Energy expenses rise by approx. 7% for every bar increase in working pressure. Choosing an appropriate compressor working pressure is crucial to achieving an effective installation.

Power Efficiency: Compressors with a variable frequency drive whose speed is controlled electronically help to keep the compressed air constant within a very tight pressure range and offer outstanding opportunities for energy savings as the power consumption is adapted to the flow requirement. At Chicago Pneumatic Compressors, we have tools and software like iTrack & Architect to determine the right usage of existing installations and simulate the energy-saving reports with the help of live recorded data. These tools help to make your existing installation better and energy efficient while maintaining design, simulation, size, and configuring a new installation setup.

Likewise, many other factors, such as air quality, noise levels, cost – initial and lifetime, maintenance, etc. —must be considered while designing an optimal solution.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.