3D printing presents unexplored possibilities in new product development

By OEM Update Editorial July 1, 2024 12:30 pm IST

Ankit Sahu, Co-Founder & Director of Objectify Technologies, explains that 3D printing technology has transformed the automotive industry by driving innovation in product development, prototyping, and the production of final components. This technology drives performance in high-end vehicles while addressing supply chain issues and promoting design flexibility and waste reduction.

How do you perceive the growth in the 3D printing and prototyping market?

India’s 3D printing market has experienced substantial growth over the past decade, with a compound annual growth rate (CAGR) of approximately 20 percent. This growth trend persists as more design and manufacturing companies focus on India. 3D printing is a highly favoured technology for new product development (NPD) and prototyping in major sectors such as white goods, automotive, UAVs, dental, and medical industries.

Additionally, aerospace, space, oil & gas, and other high-value engineering components have begun using 3D printing for small-batch production, addressing supply chain challenges. Understanding 3D printing technology in the market has carved out a niche within the manufacturing technology sector. The use cases and general qualification guidelines in different sectors have instilled great confidence in the industry, leading to the production of end-use components and critical assemblies.

Please discuss the impact of 3D printing technology on the automotive industry.

Over the past three decades, the global automotive industry has been a prime driver of the growth of 3D printing technology. Automotive companies have leveraged this technology for new product development, prototyping, and vehicle testing. They use 3D printing for final end-use components in their vehicles to enhance performance, especially in racing and high-end cars like Czinger.

In India, the prototyping market for 3D printing in the auto sector is substantial. Roughly 35 percent of 3D printed prototypes sold in the country are for the automotive industry. However, due to India’s cost sensitivity, enabling production through 3D printing will take time. This is because the technology is expensive, and economies of scale are not well supported.

How does your business collaborate with the automotive sector regarding parts manufacturing using 3D printing?

Our team possesses extensive expertise in collaborating with the automotive sector to employ 3D printing for metal and polymer applications. Specifically, we have undertaken projects involving diverse components, encompassing body panels, lights, bezels, glove boxes, and body trims, using polymer 3D printing.

Furthermore, our utilisation of metal 3D printing has produced numerous engine components and body structural parts. Notably, during the transition from BS IV to BS VI standards, we provided pivotal support to leading automotive OEMs in the development of engines. The burgeoning electric vehicle market is actively harnessing 3D printing for endeavours such as fabricating battery panels and grids.How do you expect additive printing to progress and enhance the value proposition of products?

The advancement of 3D printing technology is progressing rapidly, with an increasing number of discernible applications. This progress is fuelled by the imperative of end-user industries to enhance the value proposition of their products in terms of time, cost, and quality. This diverse array of offerings equips supply chain professionals with superior options for presentation within their organisations, thereby enhancing the flexibility and resilience of their systems. The range of available materials has expanded. There exists a delineation of data about each material and the associated qualification paradigm. This development has empowered engineers to integrate the technology into their products.

How are manufacturers leveraging 3D printing technology to streamline production and expedite delivery times for tooling?

The design freedom afforded by 3D printing technology gives designers a distinct advantage, resulting in increased design iterations and a more streamlined process. Eliminating tooling costs has led to a quicker turnaround and improved component integrity. Within the tooling industry, 3D printing is leveraged for diverse applications, including welding, assembly, and painting fixtures, capitalising on its design freedom and rapid turnaround capabilities.

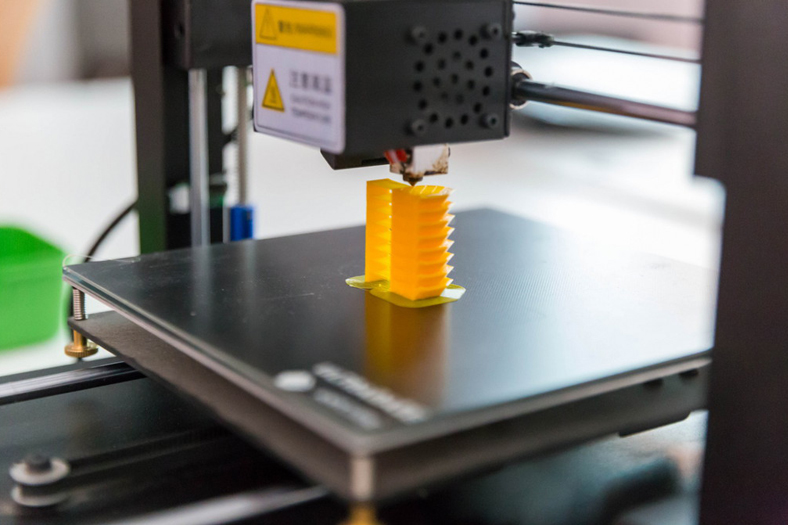

How do you envision 3D printing technologies to advance in design flexibility and waste reduction?

The additive manufacturing capability of 3D printing enables the production of intricate parts with near-net shapes. It leads to significant advantages in material conservation, reduced carbon footprint, and minimised waste. This manufacturing method also allows for improved design integration and a reduction in the number of assemblies and components within a system.

Advancements in technology, including improved printing precision and better material capabilities, have increased the industry’s confidence in adopting a risk-driven approach. It has resulted in numerous new applications and use cases across various industries.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.