Industrial automation and robotics for safer factories

By OEM Update Editorial June 19, 2024 6:58 pm IST

Technological advancements in AI, ML, IoT, and Smart Factories are bringing a sea change in industrial automation to boost Indian manufacturing performance and stressing the need for safe automation. These technologies simplify complex processes and impact various sectors and applications in daily life.

The world continually relies on technological progress. Fundamentally, the need for sophisticated solutions creates a funnel through which machine development and human resources serve as catalysts to produce simplified technological outcomes. These technologies’ influence on many sectors and application levels, particularly in industrial automation, is evident in our daily lives. The performance of Indian manufacturing and machinery is increasing because of technological investments, which further affects the requirement for safe automation and the industrial environment.

Automation with AI, ML, and IoT in smart factories

Few advanced technologies, such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) that are used in smart factories are on the verge of changing the future of automation to enhance their operations. These technologies enable real-time data analysis, predictive maintenance, and process optimisation. As humans and machines work more closely together, the efficiency of work practices improves. This collaboration has become increasingly common across various industries, from manufacturing to service sectors. However, ensuring safety during this interaction is crucial. As the proximity between humans and robots increases, so does the demand for robust safety measures.

Automation and robotics solutions aim to boost productivity and efficiency. By automating repetitive tasks, organisations can achieve higher output with fewer resources. Robotic process automation (RPA) is gaining traction in various sectors, including finance, logistics, and manufacturing. Many challenges to be addressed to ensure safe human-robot collaboration (HRC). New technologies and solutions are necessary to facilitate safer interactions. These solutions encompass the entire safety function, from sensors that detect human presence to the logic governing the robot’s actions and the actuators responsible for physical movement. A safe collaborative environment is guaranteed when all these components work together seamlesslyd. Whether talking about robots or collaborative robots (cobots), prioritising safety for humans, machinery, and the environment remains crucial.

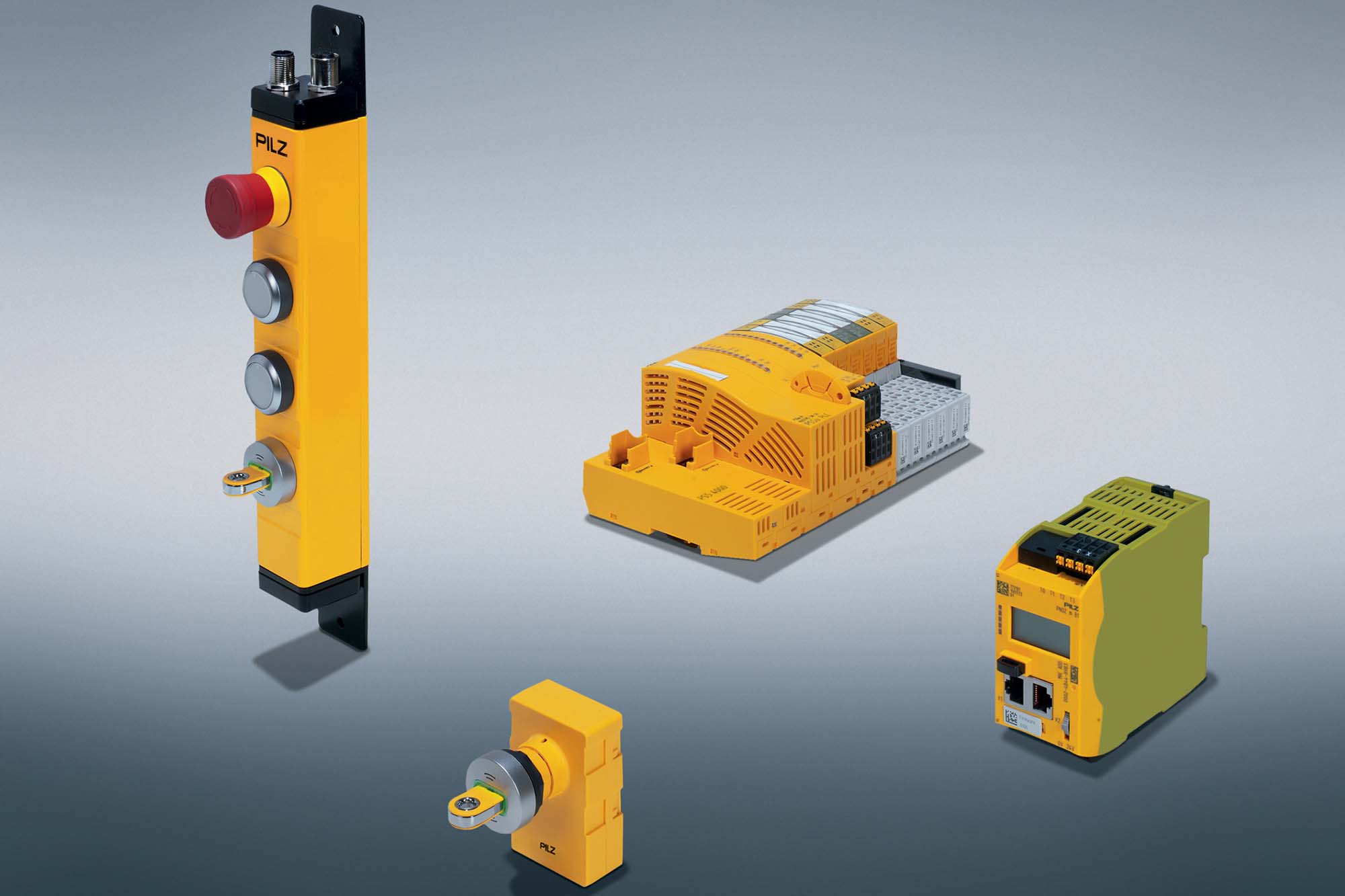

Consequently, there is a significant demand for safety equipment for automation solutions. Pilz India offers a comprehensive range of reliable and secure industrial automation solutions. These solutions help businesses meet production targets and ensure worker safety. Pilz designs to optimise production processes, control costs, and uphold the highest safety standards. The automation system PSS 4000 ensures the optimum interaction of hardware and software components, networking devices and real-time Ethernet. Through Pilz’s PNOZmulti 2 configurable control system, multiple safety functions can be implemented on plant or machinery. Pilz offers a comprehensive suite of solutions to enhance safety and efficiency in robotic applications. Also, Pilz provides light beam devices (PSENopt) for material handling, coded safety switches (PSENcode) for precise monitoring, and the integrated PSENsgate safety gate system. In this way, Pilz’s holistic approach ensures seamless human-robot collaboration while maintaining safety standards.

Enhancing machinery access control with IAM solutions

Controlling access to machinery is critical. It includes employee protection, liability protection, productivity, and data protection factors. Pilz’s Identification Access Management (IAM) solution electronic keys provide more security than classic keys. Because all too often, they are inserted in the machine and thus offer just as little security as password protection, as the password is commonly known. The Identification and Access Management solution by Pilz through PITmode provides a robust framework for managing permissions.

Only authorised personnel gain secure access, preventing unauthorised entry and minimising risks. PITmode streamlines the process of selecting operating modes. Whether in manual, automatic, or maintenance mode, the system ensures compliance with safety standards. Operators can confidently switch between modes, optimising productivity without compromising safety. The Pilz portfolio includes the PITmode operating mode selector for secure changeovers, the PITenable enabling switch for safe work in hazardous areas, and modern PMI operator terminals for intuitive interaction.

Overall, Identification and Access Management (IAM) offers a solution to the multifaceted challenges of access control. Whether streamlining machine access or managing employee permissions, it specialises in tailoring solutions to suit specific needs. Pilz covers straightforward authentication processes to intricate access management protocols, including ensuring functionally safe operating modes and electronic maintenance safeguarding. Moreover, its robust security measures extend to safeguarding invaluable data from unauthorised access and potential cyber threats to industrial operations.Ensuring safe human-robot interaction

With decades of expertise, Pilz has etched its name as a global leader, committed to automating plants, factories, and machinery while ensuring the safety of humans, equipment, and the environment. Pilz India supports safe control systems, sensor technology and a safe robot. Ensuring safe interactions between humans and robots is paramount. A holistic portfolio of services tailored to the entire life cycle of a robot system addresses this challenge. It includes process analysis, risk assessment, CE marking compliance, collision measurement, and training in robot safety.

Adhering to standards such as DIN EN ISO 10218-2 and ISO/TS 15066 is crucial. These guidelines provide a safe robot design, operation, and maintenance framework. ISO/TS 15066 defines limit values for robot collisions. Implementing collision measurement systems ensures that robots avoid harmful impacts on humans or other objects. The company paves the way for safer human-robot interactions by combining these elements. The shift toward digitalisation involves integrating digital technologies into various business operations. Compliance with guidelines related to workplace safety, environmental impact, and data privacy is crucial. Organisations must ensure that their automation solutions meet safety standards set by regulatory bodies. Automation solutions are becoming more customisable and adaptable. Modular robotics systems allow organisations to configure robots for specific tasks quickly. Flexibility is essential to accommodate changes in production requirements. Agile manufacturing processes enable rapid adjustments to meet market demands.

Conclusively, striking the right balance between perceived advantages and cost constraints is crucial for organisations within the automation field. Traditionally, safety and security are viewed as cost centres. However, safety and security are no longer optional in the evolving manufacturing landscape—they are imperative. Manufacturers aiming to export their machines globally face intricate compliance and legal challenges.

Pilz guides through conformity assessments. It clarifies safety compliance formalities for local acceptance, integrates safety practices into day-to-day activities, and makes machines, the environment, and the workforce safer.

==========

Source: Pilz India Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.