NORD ATEX-Certified drive solutions redefines safety and efficiency

By OEM Update Editorial April 22, 2024 6:48 pm IST

NORD explosion-protected electric motors are ATEX and HazLoc certified and suitable for usage in category 2D or 3D dust environments. NORD DRIVESYSTEMS’ energy-efficient IE5+ synchronous motors ensure maximum efficiency and operational dependability. The IE5+ motor generation from NORD DRIVESYSTEMS ensures the greatest degree of efficiency and operating dependability.

NORD will showcase its ATEX-compliant drive solutions for the process sector at ACHEMA from June 10-14, 2024. The focus is on ATEX-compliant drive solutions for the process sector, as well as the heavy-duty MAXXDRIVE® industrial gear unit, which is ideal for agitator and mixer applications. The innovative decentralised NORDAC ON/ON+ frequency inverters, the breakthrough DuoDrive geared motors and IE5+ synchronous motors, and the NORDCON APP with NORDAC ACCES BT will also be highlights of the trade exhibition. Interested trade visitors may learn more about NORD’s diverse solutions at the trade show grounds in Frankfurt am Main, Hall 8.0, Stand B52.

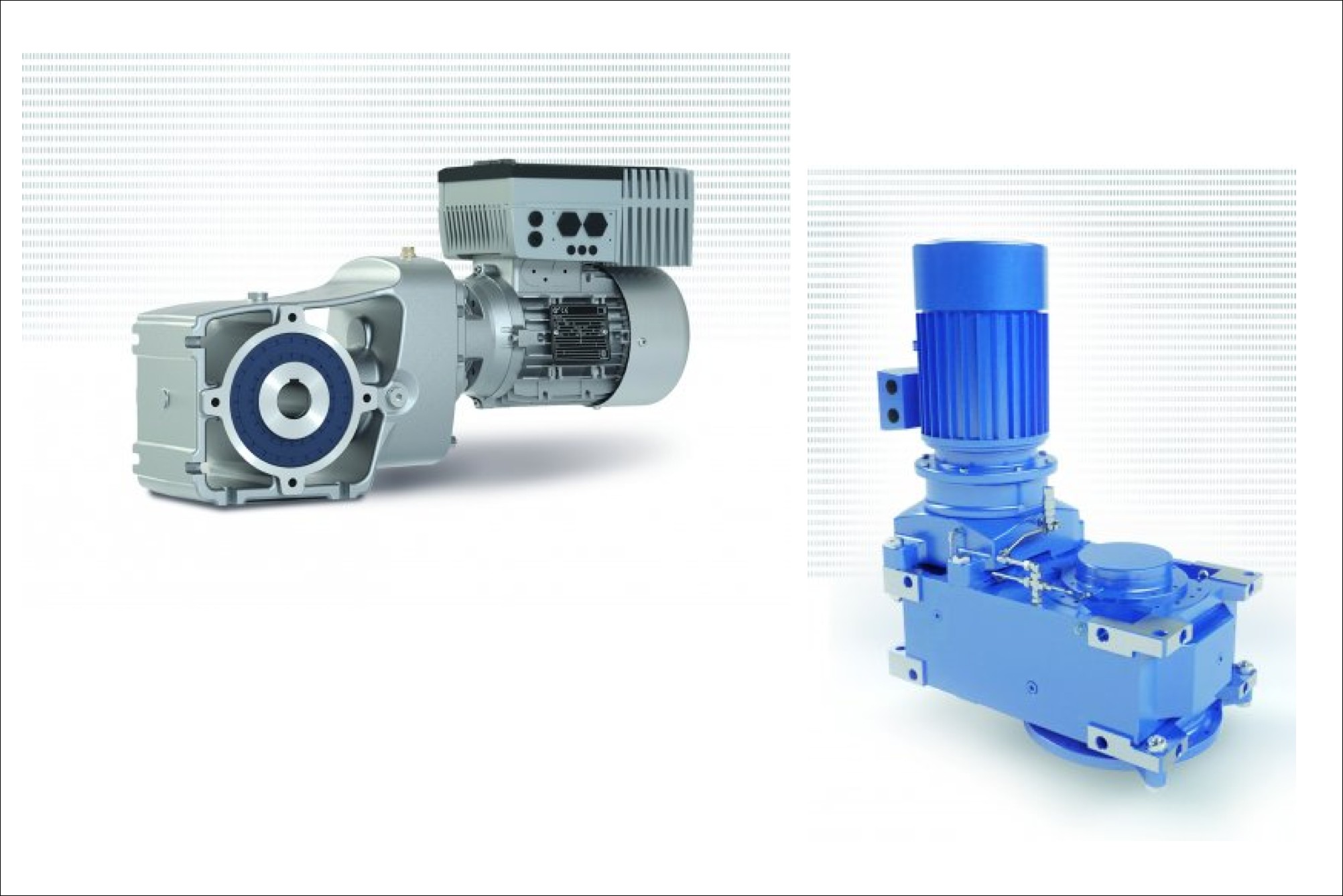

NORD-drives-solutions-ATEX: NORD has decades of experience with gas and dust explosion protection and offers particularly robust electric motors with powers from 0.12 to 200 kW especially for this field of use Image: NORD DRIVESYSTEMS

Whether in the chemical, pharmaceutical, or food sectors, businesses that extract, transport, or process raw materials demand industry-specific, creative driving solutions. As a system provider, NORD provides matched drive systems consisting of a gear unit, motor, and drive electronics that are suited to the specific needs of the customer application.

ATEX drives for explosion-protected areas

Flammable gases and dust in the processing industry pose major safety hazards. NORD has decades of expertise in gas and dust explosion prevention and provides exceptionally durable electric motors with powers ranging from 0.12 to 200 kW, designed specifically for this application. The explosion-proof electric motors can operate in category 2D or 3D dust atmospheres (zones 21 and 22), as well as category 2G or 3G gas atmospheres (zones 1 and 2), and are ATEX and HazLoc certified. The dust-protected motors fall under the ignition protection category Protection by enclosure. Depending on the needs, the gas explosion protection motors are offered in the following ignition protection classes: improved safety (e), pressure-resistant encapsulation (d/de), and non-sparking design.

Industrial gear units for high torque applications

NORDs MAXXDRIVE® industrial gear units power heavy-duty applications such as agitators, mixers and grinders in food or cosmetic production. The parallel and right-angle gear units cover a speed ratio range from 5.54:1 to 400:1 and with a first-stage gear unit, even up to 30,000:1. They feature:

High output torques from 15 to 282 kNm for reliable operation even under extreme conditions Torsionally rigid, one-piece UNICASE housing for a longer bearing life and efficient power transmission Large low-friction roller bearings for extremely high radial and axial load capacities and a long service life High-precision axis alignment for guaranteed quiet running

A SAFOMI-IEC adapter may be added to industrial gear units for mixer and agitator applications.The adapter is available for parallel gear units in sizes 7 to 11, allowing for maximum output torques ranging from 25 to 75 kNm.The adapter is compact and simple in design and has an integrated oil expansion volume; oil tanks and hoses as well as the radial shaft seal that is subject to leakage and wear between gear unit and IEC cylinder are therefore not required.

Decentralised drive electronics

The NORDAC ON frequency inverters are part of the NORD modular system and may be seamlessly integrated with the manufacturer’s motors.

NORDAC ON is for asynchronous motor applications, whereas NORDAC ON+ is for synchronous motors with high efficiency (IE5+). The inverters are intended to handle power outputs ranging from 0.37 to 3 kW.

Energy-efficient IE5+ synchronous motors

The IE5+ motor generation from NORD DRIVESYSTEMS guarantees the highest level of efficiency and operational reliability, thanks to IE5+ technology. The motors are available as a TENV smooth-surface motor, as a TEFC motor with cooling fins and as an integrated DuoDrive motor. The latter combines a high efficiency IE5+ motor and a single-stage helical gear unit in one housing. The IE5+ synchronous motors with motor efficiencies of up to 95 percent are available in the TEFC version with a power of up to 4.0 kW, in the TENV version with up to 2.2 kW and in the DuoDrive version with up to 3.0 kW.

Mobile maintenance and commissioning

NORD’s NORDCON APP for mobile maintenance and commissioning of NORD frequency inverters allows for the diagnosis, analysis, parametrisation, and monitoring of drive systems using a mobile terminal device for service purposes. The NORDAC ACCESS BT is a Bluetooth stick that connects directly to the frequency inverter, allowing for quick mobile access to driving data while also providing access control

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.