Connectivity plays a significant role in revolutionizing automation

By OEM Update Editorial December 5, 2023 12:01 pm IST

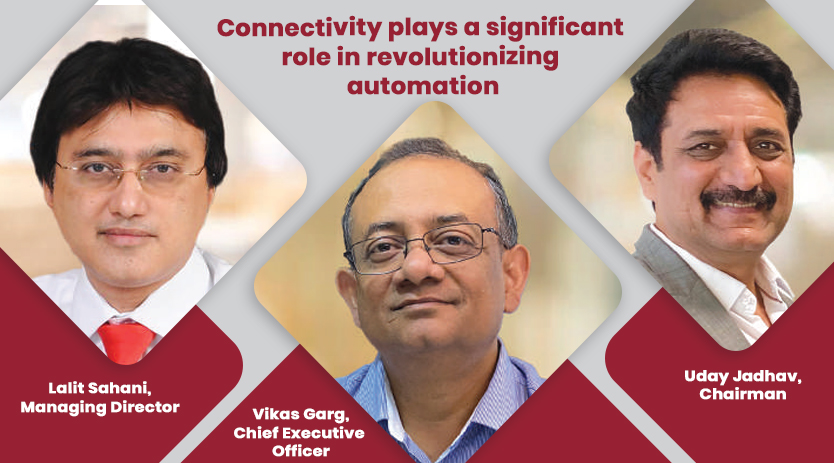

Lalit Sahani, the Managing Director, Vikas Garg, CEO, and Uday Jadhav, the Chairman of UL Group of companies, jointly emphasize their collective commitment to delivering network solutions that enable seamless connections across diverse systems. The UL Group’s comprehensive product portfolio comprises connectors, communication cables, interface, Protocol convertors – all classified within the overarching category of connectivity solutions. In pursuit of this goal, they have carved out well-defined strategies.

Please elaborate on the technological advancements happening in the automation industry.

Vikas: On the automation side, the technology is evolving from hardware to software, with data stored in a hardware device being transported to the cloud. For instance, earlier controllers, industrial gateways, routers, were used to capture data and push to cloud, now for some applications controllers are getting designed in the cloud and sensors move data directly for processing and It marks the first major change linked to digitization and IoT processes. The shift is happening very fast, in process industries the change takes more time because of the complexity, but it has already gained speed. In today’s automation world, people are focusing on enhancing productivity and data communication, using this data for the safety of operations and better information flow. Hence, the whole concept of automation is thus evolving to embrace these massive changes.

Please provide insights into the technological solutions and other product offerings by UL.

Vikas: UL operates within three primary segments. The first segment involves a value-added distribution model to collaborate with prominent MNC companies in the technology sector. In this capacity, UL provides connectivity, interface and communication solutions in industrial automation. These solutions are valuable to automation Original Equipment Manufacturers (OEMs) which includes all Automation Manufacturers, enabling them to leverage this technology to craft solutions for their larger end-users. A mutual dependency exists between UL and OEMs, where UL plays a pivotal role in supplying technology upgrades, particularly in communication networks.

To illustrate, consider a scenario where an end-user customer has a system comprising various automation technology platforms like Ethernet , Profibus , Profinet etc across mulptiple locations / continents. These OEMs operate on distinct platforms, and when it comes to digitalization and acquiring essential data, extracting it from these diverse platforms can be quite challenging. This is where UL Group steps in. It offers solutions and services capable of collecting data from these platforms and consolidating it onto a unified platform, making the data readily accessible for further utilization.

Lalit Sahani: The current focus of UL is collaboration with the multinational corporation Eaton, which has designated it as a certified CAP (Certified Assembly Partner) for its Crouse-Hinds series explosion-protected products. Automation Expo turns out to be the ideal platform to announce this significant partnership. The launch marked UL’s official status as first certified CAP partner in India.

What certification and standards does the UL Group adhere to in its operations?

Vikas: In the context of oil and gas applications, specific certifications are required to ensure the suitability of products for installation. These certifications are ATEX and ICEX, signifying that the products and solutions provided comply with safety regulations for use in hazardous areas.

As UL Group has become Eaton’s certified assemble partner, it manufactures these solutions at a facility in Pune, India. These products will be as per Eaton’s certifications. A certification team from Germany recently audited the facility and granted their approval, affirming that the Pune facility is well-suited to produce these certified solutions.

This development represents a significant “Make-in-India” initiative. It’s a notable shift for Automation OEMs , who previously sourced these products from Europe , USA or China. They will now access the same products manufactured in Pune, India. This change offers two key advantages: first, it is cost-effective due to local production, and second, it enables faster customer service delivery. This will greatly benefit our customers who can effectively provide offerings to their oil and gas customers.

Which industry segments and infrastructure sectors is UL currently involved with?

Vikas: UL maintains a wide-ranging presence across diverse industries, from automotive to pharmaceuticals and the oil and gas sector. Moreover, we actively work in the segments such as cement, power generation, and metal industries, where UL’s function is a key partner in automation. Essentially, UL offers services wherever automation plays a pivotal role.

In addition, UL has broadened its product offerings to encompass the railway and metro sectors. This expansion aligns with the government’s emphasis on developing infrastructure, particularly in roads and railways. Within these sectors, solutions for networking and crucial safety products are available. Considering the recent incidents within railway sector, there is a heightened focus on enhancing safety standards. UL is well-equipped with the appropriate products to meet these stringent requirements.

How does UL balance R&D and innovation in its manufacturing processes?Vikas: Research and development (R & D) is integral to UL, which equates it with innovation. The division that dedicates the most effort to innovation within the company is its manufacturing division. While the business activity may involve creating new products, UL is committed to and heavily invested in innovation, particularly within the manufacturing facility.

Which connectivity solutions are being employed by automation companies?

Vikas: The connectivity solutions are versatile and compatible with various platforms, including Ethernet and ProfiNet, which different automation companies utilize. The solutions for each network enable seamless connections between different systems. These solutions encompass connectors, cables, cabling systems, and communication interfaces, collectively called connectivity solutions.

To define UL’s role concisely, think of UL as the circulatory system within the world of automation. Much like the human body has vital organs like heart, kidney, lungs, major automation OEMs represent these essential organs. On the other hand, UL plays the crucial role of ensuring the smooth flow of data and communication within the automation ecosystem just like Arteries carries oxygen rich blood to Heart. UL’s function is akin to providing the arteries that deliver essential data and oxygen to the automation systems. With efficient functioning, the most robust automation systems thrive.

How does UL collaborate with automotive manufacturers regarding connectivity solutions?

Vikas: In the automotive industry, one key aspect is providing diagnostic services due to the rapid technological advancements that occur globally. The automotive sector is known for being quick to embrace new technologies. So, while discussing digitization, IoT, and advanced Manufacturing Execution Systems (MES) solutions, the critical factor is having access to data. However, data availability can be challenging, especially in heavily congested networks. This is where the company’s solutions come in. UL received significant orders from major automotive manufacturers utilizing its network diagnostic services. Both offline and online network diagnostic tools evaluate the network’s overall health.

How is UL responding to the industry’s evolving landscape?

Vikas: India is indeed undergoing a significant transformation, and it’s not a matter of choice but a necessity. In the past, the focus was on the stability and availability of systems and plant uptime. These were the key factors considered when evaluating systems about two decades ago. However, technology has since evolved to become more stable and robust. Now, the requirement from the system is to provide the necessary information to enhance profitability and productivity. There’s now a fragile boundary between production systems and business operations. The flow of information from plant networks to business data is where the crucial shift needs to happen for sustainability.

India, known for its engineering talent, is advancing rapidly. The main challenge has been the availability of semiconductors due to over-dependence on imports. However, with the recent initiatives led by Hon. PM Modi’s initiatives, there is substantial investment and support for the semiconductor industry. It is believed that India will be at the forefront of global technological advancements within the next two years.

What initiatives has UL undertaken about localization efforts?

Vikas: UL tied up with Eaton to begin assembling and manufacturing ATEX panels in India, previously not undertaken by Eaton. This initiative by UL Group aligns with the ‘Make in India’ campaign, a crucial step for India to become one of the top two or three largest economies globally. So, ‘Make in India’ is a vital initiative to promote self-reliance in technology and product manufacturing. Additionally, UL is a JV partner of a Taiwanese company that specializes in network switches, which play a significant role in communication and connectivity. The company is exploring options to produce these products locally in India, especially for applications in railways, metro systems, and highways, where communication is essential. For example, when travelling from Pune to Mumbai and encountering traffic in Lonavala, one must rely on communication for updates on traffic, toll collection, CCTV monitoring, and automated fines. Networking is the lifeline of every activity today.

There is a substantial push towards localization, even among large corporate houses , The government is also encouraging localization efforts, such as Apple’s assembly and manufacturing in India, the establishment of semiconductor plants, investments in hydrogen, solar power plants, and lithium ion battery production. These developments are progressing very fast and hold the potential to help our economy in line with what we all wish.

What future projections does UL envision for automation in the coming years?

Vikas: UL is very well placed for growth. Over the past two decades, it has developed a robust infrastructure and product portfolio and made more valuable additions. In fact, as evidence of its potential, in the previous fiscal year ending in March 2023, UL Group achieved a remarkable 30 percent YOY growth. More ambitious projections are being made this year, with a clear path of higher sustainable growth over last year. So, UL has set a challenge to become a significant player in the field of Industrial Automation Products and Solutions with focus on innovation, customized solutions and make things simpler for our esteemed customers. While this represents a rapid pace of growth, it’s not just wishful thinking –concrete plans are afoot with a well-defined strategy to achieve this objective.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.