LAPP unveils seamless ethernet networking for industrial connectivity solutions

By OEM Update Editorial December 5, 2023 11:55 am IST

LAPP has introduced a groundbreaking Single Pair Ethernet (SPE) portfolio, revolutionising industrial automation. This technology enables seamless networking, offering cost-effective and space-efficient solutions for efficient production facilities.

LAPP introduced its pioneering Single Pair Ethernet (SPE) portfolio. This comprehensive range marks a significant leap forward in the industrial automation landscape.

The vision of a fully connected factory, inclusive of the Internet and the cloud, is becoming a reality. In the industrial landscape, two predominant systems have traditionally coexisted: Ethernet, a well-established communication standard at the control levels of the automation pyramid, and diverse fieldbus systems prevalent in the lower field levels. To facilitate seamless networking, a new infrastructure was imperative. This infrastructure needed to align with the Ethernet networks at higher levels, all while being cost-effective and space-efficient, addressing the spatial constraints present in numerous machines and systems.

Seamless Ethernet networking with SPE

The solution lies in Single Pair Ethernet Technology (SPE), which facilitates consistent and uniform Ethernet networking, extending all the way down to the field level, commonly referred to as the sensor/actuator level. It enables the real-time transmission of energy and substantial data volumes using only one data pair connection, deviating from the standard four data pairs found in typical Ethernet cables. The integration of artificial intelligence and big data allows for the optimization of production facilities. SPE stands out as an ideal solution for applications with limited space, providing efficiency gains in weight and space utilization. This positions SPE as nearly as fast as multi-pair Ethernet, while offering the advantage of covering significantly larger distances and requiring less installation effort.

LAPP as a Pioneer

Since 2019, LAPP has collaborated with numerous electrical connection companies, including cable and connector manufacturers, within the SPE Industrial Partner Network to drive the advancement of Single Pair Ethernet (SPE) technology. Over time, SPE has achieved international standardization, laying the groundwork for its global expansion. Several recommendations have been incorporated into the IEC 63171 standard for industrial connectors. LAPP favors the connector face specified in accordance with IEC 63171-6 and actively contributes to the dissemination of this standard through its involvement with the SPE Industrial Partner Network. Additionally, corresponding guidelines for SPE networks have been developed by user organizations like PI for PROFINET or ODVA for ETHERNET/IP.

First all-round portfolio

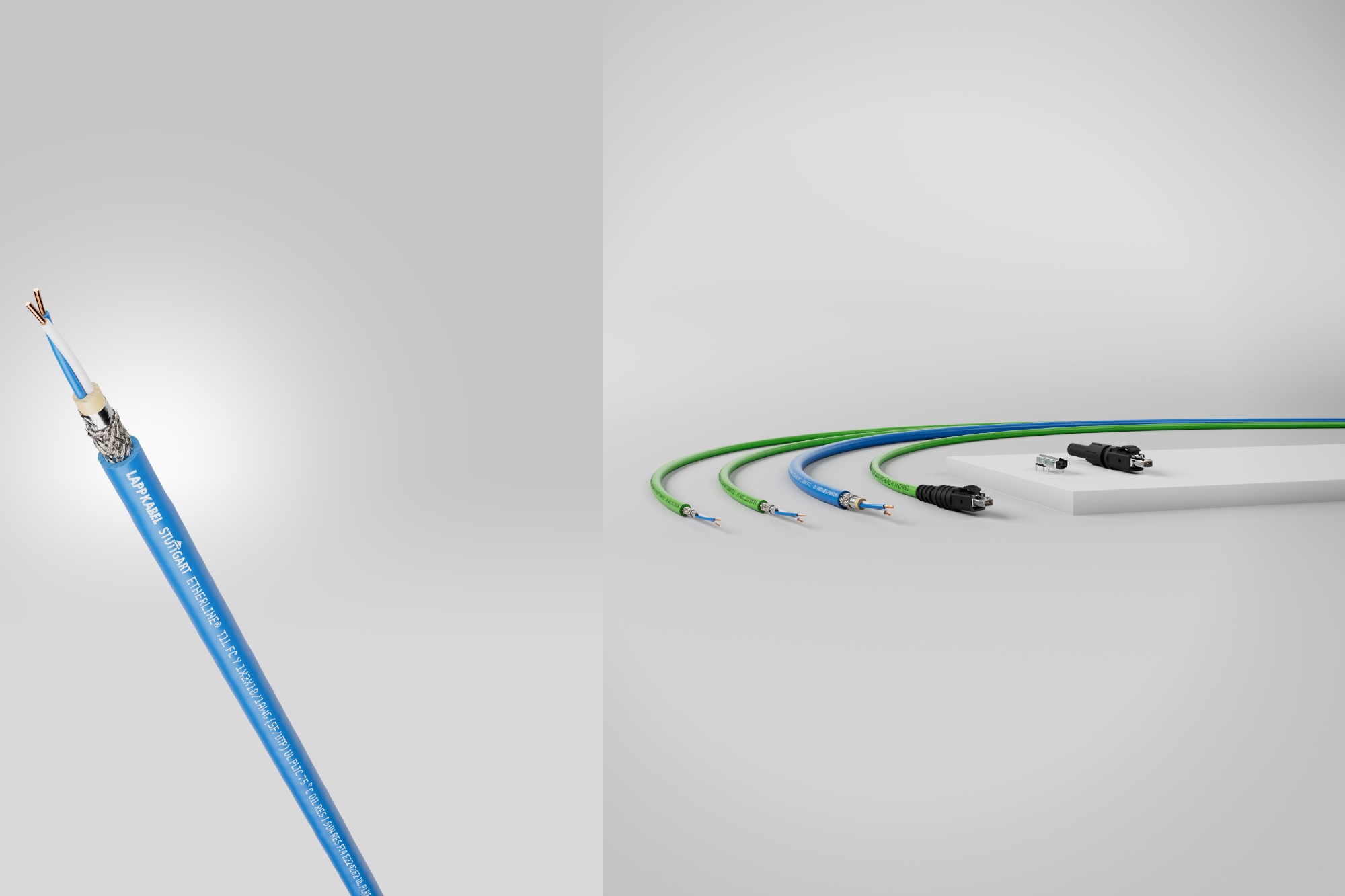

“In our view, the Single Pair Ethernet technology is a real game changer in industrial automation. This is why it was our aim to offer our customers SPE connection solutions from a single source as quickly as possible. This saves time and professional advice is also available from our top-notch experts,” explains Steffen Schneider, Product Manager at LAPP. The world market leader for integrated solutions in the field of cable and connection technology started developing cables at an early stage. With the ETHERLINE® T1 product family, a portfolio of Single Pair Ethernet cables is available for use in industrial machines and systems.

Another new product available is flexible, shielded SPE data cable ETHERLINE® T1 FLEX with PVC outer sheath, space-saving, single-pair cable design with UL approval. It is also available in dimension (26 AWG). In addition, there is the highly flexible SPE data cable ETHERLINE® T1 with PUR outer sheath and UL approval. It connects terminal devices at sensor/actuator level to the Industrial Ethernet – even in tight spaces. Its double shielding and PUR outer sheath, means the cable – which is suitable for use in cable chains – is well protected against external interference. The cable has been successfully tested on more than three million bending cycles. Both variants enable full interoperability of field devices and systems from different manufacturers by seamlessly connecting to the Industrial Ethernet network and are suitable for transmitting analogue and digital signals in the frequency range of up to 600 MHz and a distance of up to 40 m. In addition, the Power-over-Data-Line (PoDL)-capable cables in accordance with IEEE 802.3bu allow simultaneous power and data supply of SPE terminal devices with low energy requirements (up to 50 W). A double shielding made of aluminium-laminated foil and copper braiding with a high degree of coverage (SF/UTP) guarantees protection against electromagnetic interference.

New: Ethernet Advanced Physical Layer for the process industry

SPE has potential in many industries. In process automation, SPE helps bridge long distances in large-sized plants, for instance in the chemical industry. Analogue cables or fieldbuses with data transmission rates of just 31.25 kbit are still used here. For distances of up to 1000 metres, additional properties for the process industry have been defined for SPE under the term Ethernet APL (Advanced Physical Layer) based on 10BASE-T1L according to IEEE 802.3cg. LAPP Advanced Physical Layer (Ethernet-APL) is specifically designed for these demanding applications in the process industry, some of which are based on SPE. Ethernet APL enables safe data transmission up to field level in potentially explosive environments. This is ensured by the “intrinsically safe” ignition protection type. It is based on the 2-WISE concept (2-Wire Intrinsically Safe Ethernet) concept according to IEC TS 60079-47. This achieves an explosion-protection technology with a high level of protection. Ethernet APL also bridges long distances of up to 1000 m. The shielded Ethernet APL data cable ETHERLINE® TL and the flexible shielded Ethernet APL data cable ETHERLNE® TL FLEX for occasional movement enable data transmission via Ethernet up to the field level in potentially explosive environments in the process industry and are UL/CSA-certified for the North American region. The “Fast Connect” structure with inner sheath also enables easy stripping and assembly of the cable. Both variants are also among the first to be commercially available.

Compatible SPE connectors

A further addition to the SPE portfolio is the compatible SPE connector EPIC® DATA SPE-6 FA M CS1 with crimp termination for AWG26 cables. This connection creates a vibration-proof connection, provides maximum contact protection between the contact and cable and is suitable for automated assembly. The SPE plug is suitable for creating a detachable SPE connection and is faster, easier and more cost-effective to install than a conventional Ethernet connector. The connector face complies with the DIN EN IEC 63171-6 standard. Its compact design enables use in tight spaces. Power over Data Line (PoDL)-capable connector can also be used for simultaneous power and data supply of SPE terminal devices with low energy requirements (up to 50 W).

Suitable for this, there is the compact SPE circuit board socket EPIC® DATA SPE-6 PCB F for connecting SPE connectors to a printed circuit board inside active devices and a connector face in accordance with DIN EN IEC 63171-6. In addition to the data supply, the socket also enables a power supply of up to 50 watts for terminal devices thanks to the Power over Data Line.

Last but not least, LAPP also possesses the shielded single-pair Ethernet patch cable, shielded on both sides, for detachable SPE connections. Over moulded connectors ensure it is held securely.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.