How connectors promote sustainability

By OEM Update Editorial November 23, 2023 12:42 pm

In industrial manufacturing, sustainability takes centre stage. It’s not just about eco-friendly materials; it’s also about optimising processes. These sustainable practices enhance efficiency, cut costs, and minimise machine downtime, safeguarding valuable resources, including employee work hours.

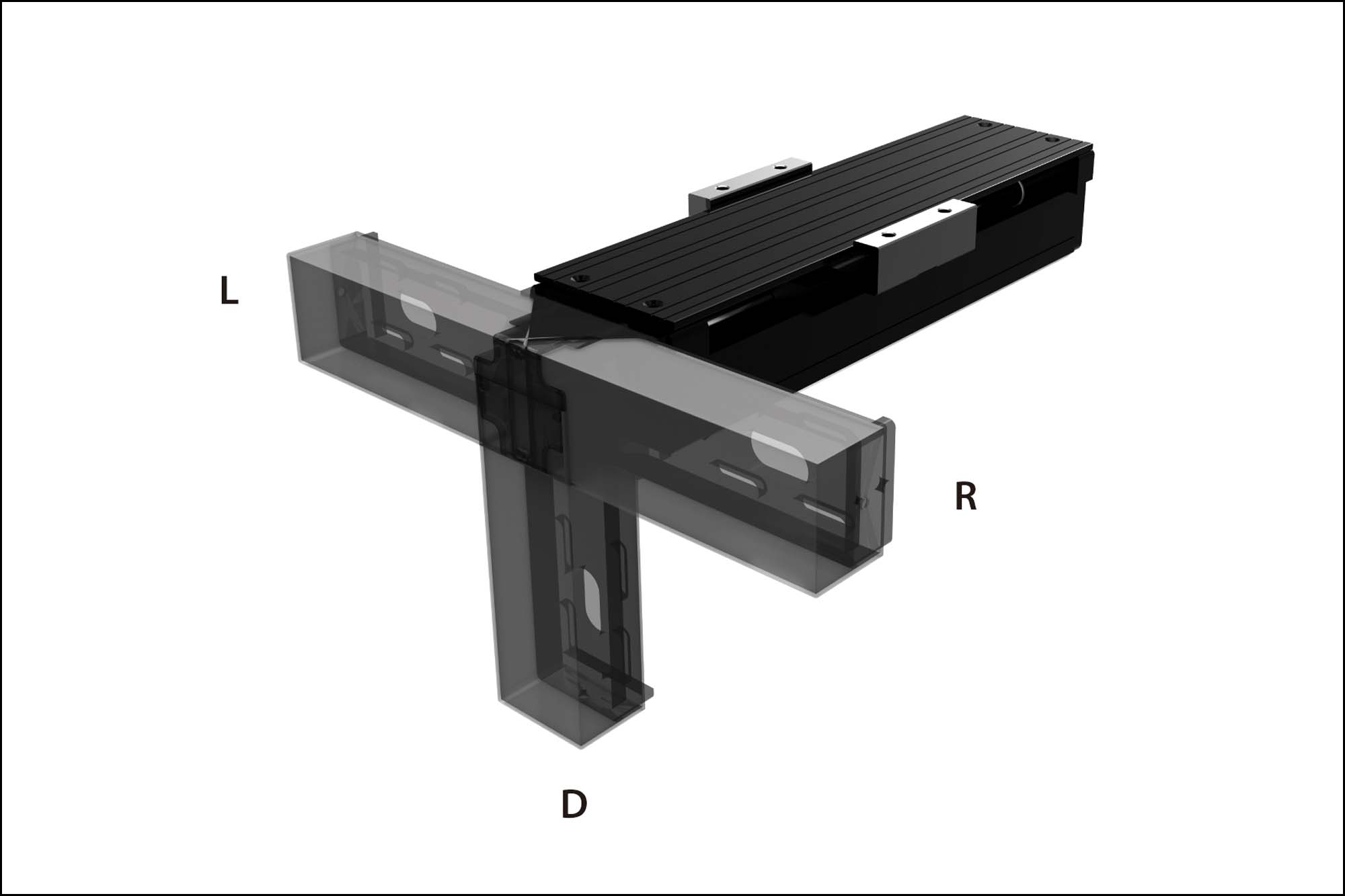

Connectors play an important role in the design of sustainable processes. It is not only the function of quickly connecting or disconnecting a machine or an attachment that is of interest. Modern connectors support the production worker in making a secure and error-free connection. This is particularly important with modern modular systems where reconfiguration is frequent. An error-free connection helps to conserve important resources such as energy and time.

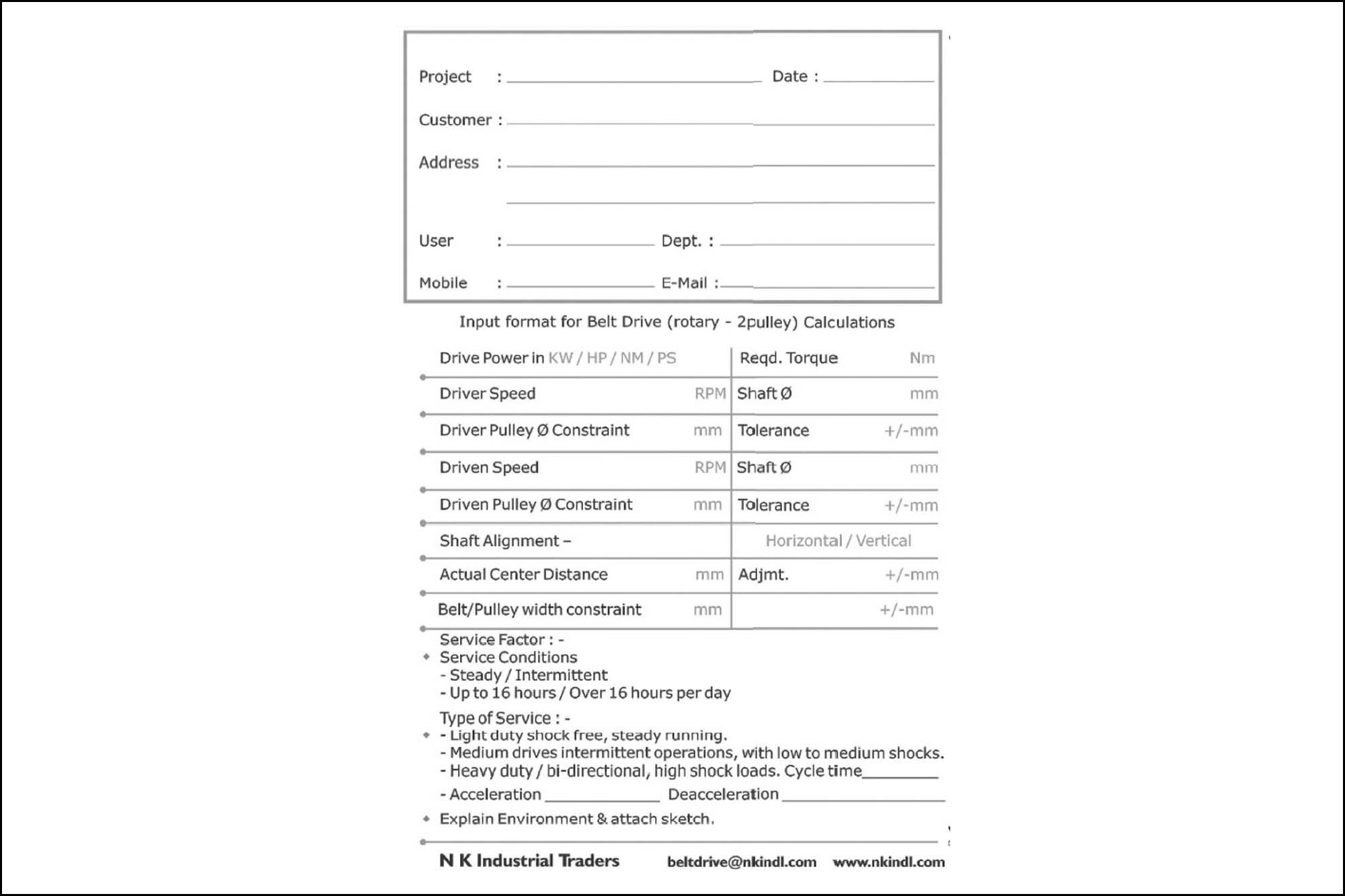

SmEC – Connector concept for modular machines and systems

One of the most important additional functions of a connector is the signalling of the mating state. The mating state contains different parameters depending on the application and the connector. The plug-in state usually answers questions like whether the connector is plugged into the correct mating connector. Is the connector fully electrically connected, or whether it is completely mechanically locked? Is the connector electrically overloaded, and are the environmental parameters (temperature, humidity, etc.) within the permitted range?

The plug-in status is signalled to the employee using an LED, a light ring or also acoustically. In the simplest case, a red/green display is sufficient for the machine operator to recognise whether a fault is present. Modern full-colour LEDs with additional flashing patterns or animations indicate other states, such as the presence of voltage. In addition to visual or acoustic signalling, a digital interface also transmits the information in greater detail to a control centre. The SmEC from the HARTING Technology Group transmits the data via MQTT or OPC-UA PubSub. The data is available in a JSON format and can be received and processed by any controller. Among other things, the Asset Administration Shell also provides the live data of the connector as a digital twin.

In addition to signalling the mating status, The SmEC actively prevents unintentional disconnection of the connector with the help of the integrated locking mechanism. This ensures that the components are not damaged and that there is no danger to people. The connector can only be disconnected after it has been de-energised and the active lock has been released. For this purpose, the SmEC has integrated voltage and current measurement that also monitors the connected machine. In this way, the current carbon footprint can be calculated based on the energy consumption data.

Data diode – Protection against sabotageThe measurement of the carbon footprint can also be easily retrofitted to old machines. A data diode protects the measuring device (e.g. the SmEC) against sabotage, allowing the data signals in only one direction. This allows data to be sent from a protected network to an unprotected network, e.g. to a dashboard – the protected network is safe from attack. For this purpose, HARTING has developed a data diode for a connector. With a data rate of up to 1Gbit/s, the usual IoT protocols such as OPC-UA, MQTT or Modbus-TCP are transmitted. Integrating a real hardware data diode, which consists of the laser diode on the transmitter side and a photodiode on the receiver side, makes it impossible for the data to flow back.

Smart ix – Small connectors with identification function

To determine whether a connector is plugged into the correct mating connector, it must be possible to identify the connector. In the simplest case, this is solved with additional electrical contacts as coding pins. Unlike mechanical coding, the machine control system determines which attachment is now plugged in. However, this method reaches its limits with large, flexible systems. An unnecessary number of contacts are consumed for electrical coding with coding pins. A more suitable variant is identifying the connector with the help of a bus system and a small microcontroller or via NFC (Near Field Communication). This gives each connector a unique ID assigned to a corresponding component (e.g. attachment or tool). This method also works with very small connectors, as seen on HARTING’s Smart ix. The Smart ix is a small 10-pole connector in which a microcontroller is integrated. With the help of the microcontroller, precise identification is possible. The ID is used in the unit/machine control to establish a link to the connected component. This way, even simple components such as lamps, door contacts or analogue sensors can be identified. The control signals to the user whether the components are plugged into the correct port.

Han Protect – Han® 3A – Simplified repair processes

During the production process, there are often unwanted downtimes because the necessary skilled personnel are off-site. For example, a defective fuse can only be changed by a suitably trained person. Since the fuse is located in the control cabinet, other people do not have access. One way to make the fuse accessible from the outside is to integrate it into a connector, such as the Han Protect. As the connector has to be disconnected to change the fuse, the work is also possible for instructed persons, especially when low voltage is involved. This speeds up the repair processes and reduces downtimes – which has a lasting effect on resources.

More information at: https://www.harting.com/IN/en-gb

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.