Visions of the future: fusion of OT and IT

By OEM Update Editorial November 23, 2023 11:08 am

This article discusses why a merger or the bridge between OT and IT needs to be crossed to advance Industry 4.0 initiatives, as well as the effect of closing the gap between OT and IT on industrial automation solutions and its market.

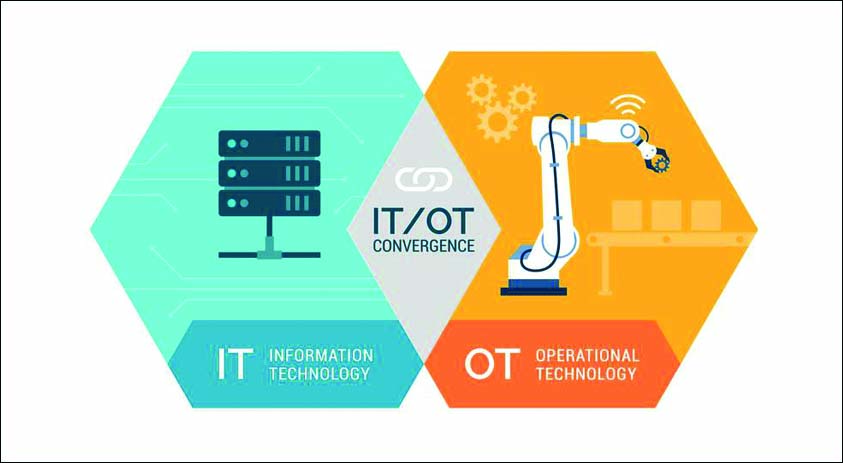

The term ‘operational technology’ (OT) was introduced to distinguish between conventional information technology (IT) services and the equivalent services tailored for the industrial sector. As you probably know, a typical consumer PC would only survive for a short time in the challenging conditions of a factory floor, and most user-friendly mainstream software can not be run on industrial equipment. The incompatibility led to the phrase ‘operational technology’, which represents the hardware and software used within the industrial sector. That bridge, however, is already being crossed. Today, OPC UA pub/sub-TSN is creating a pathway for merging IT and OT into one seamless entity within the industrial and tech communities.

Industrie 4.0 and the differences between OT and IT

Operational technology refers to the hardware and software technologies used in managing or controlling physical devices, equipment, and systems. OT has a physical control process component to it, which makes it a concept designed for the industrial sector in which ‘physicality’ rules. The industrial shop floor is a physical and harsh environment; heavy equipment must be controlled in line with a master production plan. OT provides the tools needed to physically control or automate the operations of these heavy pieces of machinery.

Regarding features, OT is designed for technologies that include the older programmable logic controller and the more current computer numerical control (CNC) systems. The visualization solutions attached to OT vary from simple digital LED screens to web-based HMIs equipped with processing resources and software to display contextual information to shop-floor operators. OT is used as a tool for industrial control or automation and is applied to control conveyor belts, CNC machines, automated assembly lines, and alert systems. Traditionally, vendors that provide OT solutions rely on proprietary hardware and software. It ensures that they have sole control over the troubleshooting and maintenance processes.

In the information age, information technology rules. That is why it is regarded as more mainstream than OT. It refers to the hardware and software used in managing data. This includes storing, retrieving, analyzing, and manipulating data. The mainstream reliance on IT within every sphere of life has led to the development of advanced IT solutions that are intuitive and easy to use when handling any form of data.

While IT relies on hardware and software to deal with data, OT relies on both to control physical entities. But with the introduction of Industrie 4.0, a new framework that juxtaposes both technological systems is required. Data and the interconnectivity between industrial assets drive Industrie 4.0. IT is expected to handle the data-analysis process, while OT is expected to evolve to manage interconnectivity and rely on IT to support seamless data management.

Closing the gap between OT and IT with OPC UA pub/sub over TSN

To achieve true industrial automation, or the lights-out factory, the gap between OT and IT must be bridged. Both technologies must be categorised under one department to develop industrial processes

that seamlessly run on both options. To achieve unification, the OPC UA pub/sub over TSN standard was developed. The first step of this standard is the unification of the diverse proprietary OT solutions running the industrial sector. A unified and open OT framework paves the way for machine-to-machine communication and data exchange.

Today, the efforts of OPC UA pub/sub over TSN and the bridge-building process to develop seamless OT and IT operations are yielding multiple fruits. One practical example can be seen from how factory owners currently leverage the industrial cloud and IoT platforms to support the development of IT applications, store data from OT assets, and facilitate the transfer of data within the factory floor.

The innovative developments in the web HMI market are another example of how successful mergers between OT and IT open up the factory floor. HMIs are important bridges. They serve as OT assets that can withstand the harsh environment of the factory floor while providing the computing resources and ease of use that IT assets guarantee.

Bridging the gap between OT and IT further creates an open playing field that stakeholders in the IT sector are currently exploring and are expected to build on shortly. Today, we have dedicated IoT stores where industrial applications can be bought, and these applications run seamlessly on smart devices, factory equipment, and web-based industrial browsers without compatibility issues.

Conclusion

An open unified technology framework is one in which OT and IT solutions are developed within a single department. Here, software developers in the IT sector can bring their UI and UX experiences to simplify industrial applications and their use. The merger will also provide more scalable infrastructure to handle the billions of industrial networks of edge and IIoT assets, which are expected to deliver the benefits of Industrie 4.0

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.