WAGO IoT Box: ready-to-use solutions for Industry 4.0

By OEM Update Editorial July 3, 2023 5:09 pm

Integrating machines and systems into the “Internet of Things” is incredibly simple with WAGO IoT Box.

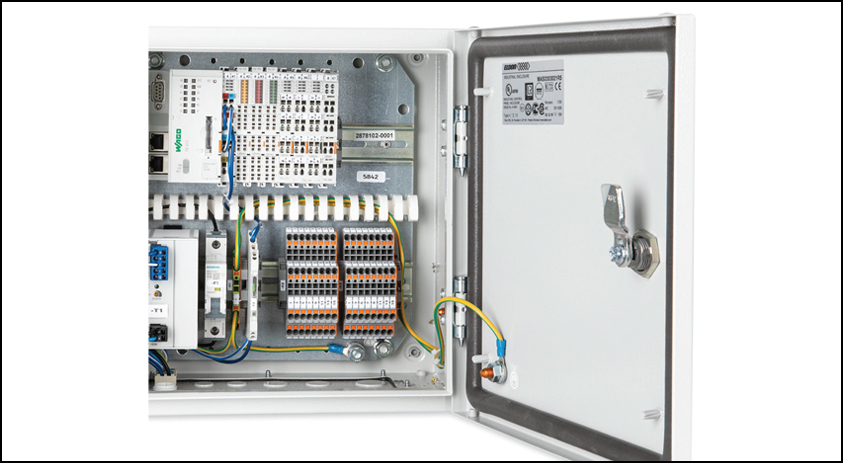

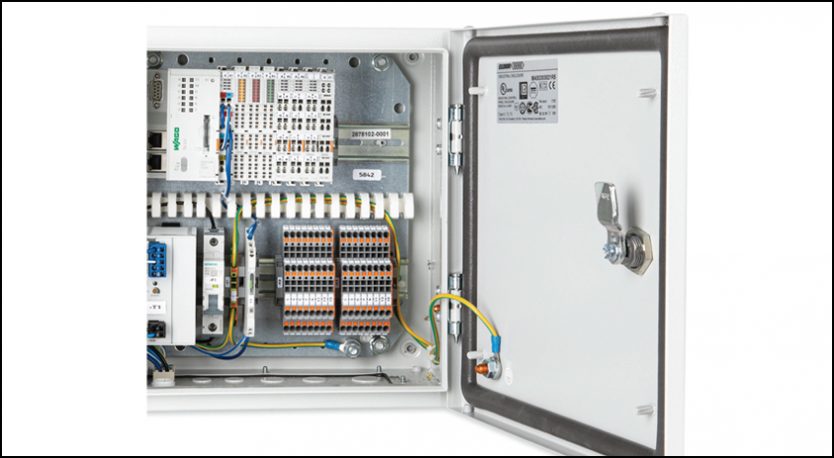

The complete system is ready for immediate use and offers all the functions required for digitalization, from signal acquisition to cloud connectivity. The IoT Box is designed as a plug-and-play device – no hardware engineering is needed. Collected data is transferred to the desired IoT application with just a few parameter settings. The hardware includes a controller with its communication interface, I/O modules with analogue and digital inputs/outputs, a 3-phase power measurement module and a 24 V power supply unit.

Depending on the application, additional I/O modules can be added later to adapt the system to specific requirements. Additional options include a protocol gateway to various fieldbus and control protocols or the evaluation and pre-processing of data using PLC functionality and/or applications under Linux®, including Docker.

Connect machines and systems.

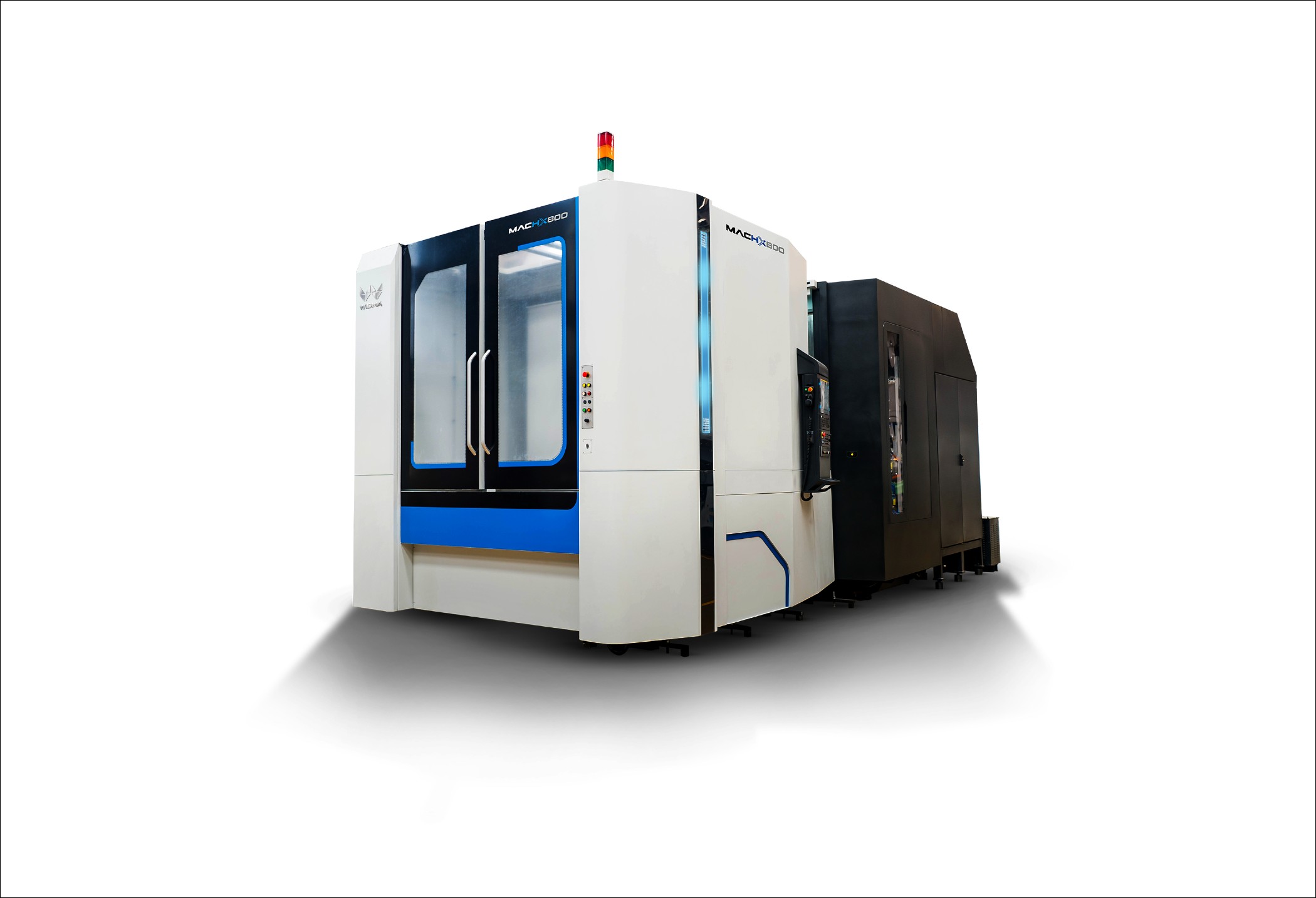

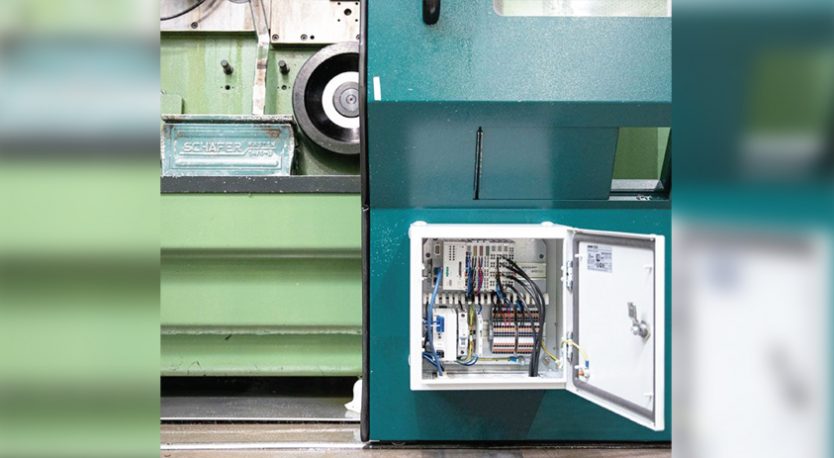

The company of the future will be one thing above all else: thoroughly networked. Anything not connected to the IT system must be connected sooner or later, especially production. Many companies are not ready for this – and their machines and systems are inherently unable to transmit data. This is the key point where the WAGO IoT Box comes into play.

Various options for connecting to the company’s IT infrastructure are available: Ethernet or WLAN connection or completely location-independent access via the mobile communication network. The necessary security is provided by separating the IT and OT networks and further measures, such as TLS encryption and VPN tunnelling, built into the PFC controllers.

For more info email at contact.india@wago.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.