Digital twins boost machine development

By OEM Update Editorial April 19, 2023 12:18 pm IST

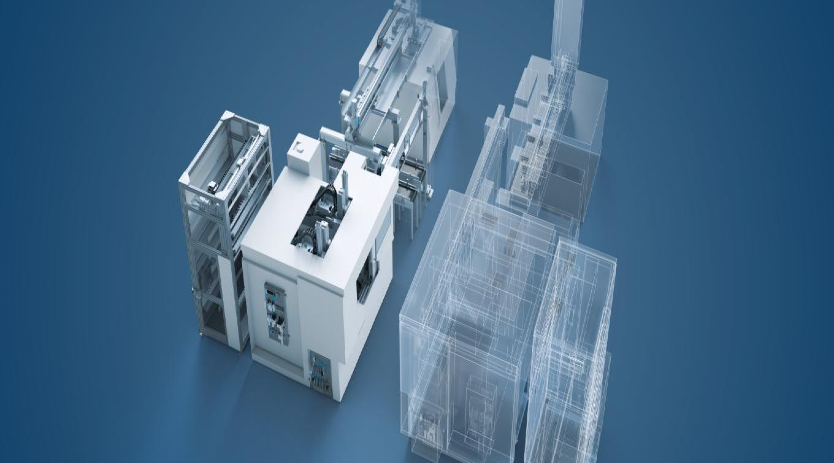

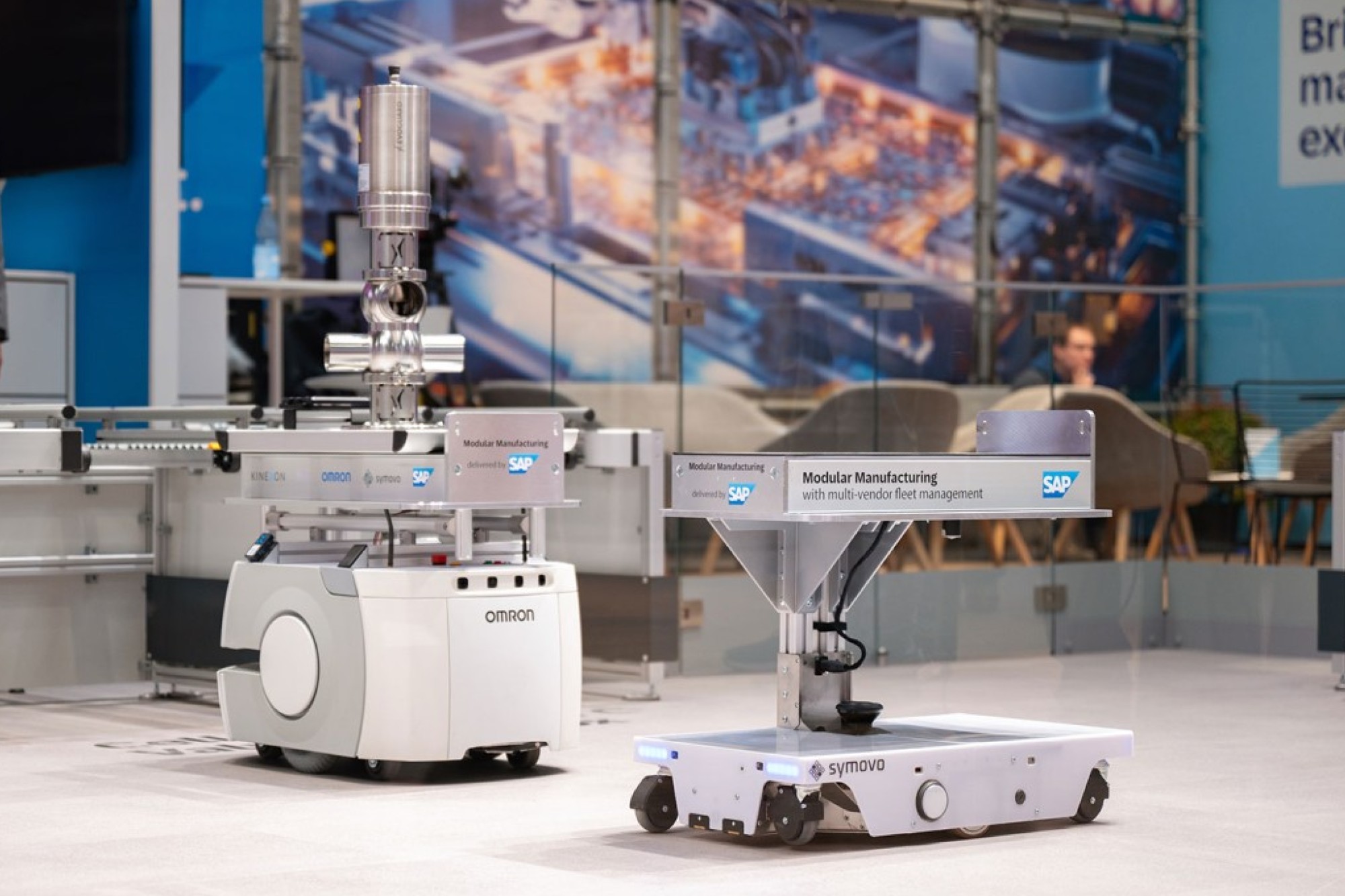

Faster time-to-market, more efficient engineering, more functionality and higher quality – these are the advantages of a digital twin for machine and plant manufacturers. Festo is working intensively on equipping its automation components with a digital twin, a digital image in the form of administration shells. The company has partnered with other German automation partners and the Industrial Digital Twin Association because standardization is what machine and plant manufacturers expect. The advantages of digital twins will be demonstrated using the engineering of a labeling machine as an example in a jointly constructed application at the Siemens booth.

Digital twins can be used application-oriented at many points in engineering. “Machine and plant manufacturers will increasingly demand digital twins in order to be able to develop their machines and plants faster and make fewer mistakes,” explains Gerhard Borho, Digitalization Director at Festo. Step by step, the “digital first” principle is being developed further: Components and machines are developed virtually as far as possible before the first hardware is manufactured – this extends to testing and system integration. Similar developments can be seen in factory planning.

Shorten project times

Shorter development times require further parallelization of development steps by the machine builders. Digital twins must therefore also accurately reproduce the capabilities of the components, if necessary down to the physical behavior. This significantly shortens the customer’s project times and increases productivity. Even before a machine developer has assembled the machine as hardware, he can simulate, test and change it again. For example, he can optimally and efficiently design and program handling systems on the virtual model. Errors can be found and corrected at an early stage, which contributes significantly to efficient and stable operation later.

Digital twins of automation components are much more than just 3D models that move virtually. They are digital images with a wide range of information about the components, including a clear description of their capabilities, documentation, behavior – for example the simulation of their kinematics and kinetics – and communication with them through to their role within the machine.

Whole life cycle in focus

The Industry 4.0 machine architecture is based entirely on digital twins, which, with their standardized communication interfaces, make life easier for practically the entire life cycle of a machine: from virtual commissioning and machine control to data collection and the resulting value-added services such as maintenance or diagnostics. Behavioral models of pneumatic functions were used for the virtual commissioning of the labeling machine mentioned. Further time savings result from reduced search times in catalogs or support portals or the creation of machine documentation. Up until now, there was a large amount of data in different formats such as CAD, PDF or even paper manuals for each automation component. Data management was therefore cumbersome and difficult to access over the entire life cycle of an automation product. This lack of digital consistency also made it difficult to fully network all objects. Festo is therefore working on seamless and consistent communication technology such as OPC-UA. Ultimately, the administration shell is used as the central information object to use digital twins over the lifecycle

Digital twins make planning and preparing a specific offer easier. “Thanks to intelligent algorithms, the components can be designed and configured optimally and at the same time in an energy-efficient manner,” adds the Digitization Director at Festo.

Benefits during commissioning

In the virtual model, the developer can test whether he can move the carriage, for example, and look at the process data from the position measuring system or the signal from the end position sensors. If he wants to create the control sequences of the machine, the developer has access to component capabilities such as extending, turning or gripping, with which he can easily put together the desired sequence.

Other value-added services can also be implemented on the basis of digital twins. Before components in operation reach the end of their service life, this is reported by condition monitoring. The digital twin of the machine could then automatically order spare parts. If there are successor models for the components to be replaced at this point in time, the customer can first test the interaction of the new components in a virtual environment and procure them appropriately.

In addition, condition monitoring can create predictive maintenance plans in conjunction with the simulation models of the digital twins. Customers can also use digital twins to develop and test later changes, optimizations or reconfigurations on the machine in advance on the virtual model and thus implement them more quickly.

Festo has brought the digital twins of its electrical and pneumatic automation products together with other component suppliers into an application where mechanical and plant engineers can experience the advantages of the digital twins live in the engineering tools from Siemens.

Shorten project times

Shorter development times require further parallelization of development steps by the machine builders. Digital twins must therefore also accurately reproduce the capabilities of the components, if necessary down to the physical behavior. This significantly shortens the customer’s project times and increases productivity. Even before a machine developer has assembled the machine as hardware, he can simulate, test and change it again. For example, he can optimally and efficiently design and program handling systems on the virtual model. Errors can be found and corrected at an early stage, which contributes significantly to efficient and stable operation later.

Digital twins of automation components are much more than just 3D models that move virtually. They are digital images with a wide range of information about the components, including a clear description of their capabilities, documentation, behavior – for example the simulation of their kinematics and kinetics – and communication with them through to their role within the machine.

Whole life cycle in focus

The Industry 4.0 machine architecture is based entirely on digital twins, which, with their standardized communication interfaces, make life easier for practically the entire life cycle of a machine: from virtual commissioning and machine control to data collection and the resulting value-added services such as maintenance or diagnostics. Behavioral models of pneumatic functions were used for the virtual commissioning of the labeling machine mentioned. Further time savings result from reduced search times in catalogs or support portals or the creation of machine documentation. Up until now, there was a large amount of data in different formats such as CAD, PDF or even paper manuals for each automation component. Data management was therefore cumbersome and difficult to access over the entire life cycle of an automation product. This lack of digital consistency also made it difficult to fully network all objects. Festo is therefore working on seamless and consistent communication technology such as OPC-UA. Ultimately, the administration shell is used as the central information object to use digital twins over the lifecycle

Digital twins make planning and preparing a specific offer easier. “Thanks to intelligent algorithms, the components can be designed and configured optimally and at the same time in an energy-efficient manner,” adds the Digitization Director at Festo.

Benefits during commissioning

In the virtual model, the developer can test whether he can move the carriage, for example, and look at the process data from the position measuring system or the signal from the end position sensors. If he wants to create the control sequences of the machine, the developer has access to component capabilities such as extending, turning or gripping, with which he can easily put together the desired sequence.

Other value-added services can also be implemented on the basis of digital twins. Before components in operation reach the end of their service life, this is reported by condition monitoring. The digital twin of the machine could then automatically order spare parts. If there are successor models for the components to be replaced at this point in time, the customer can first test the interaction of the new components in a virtual environment and procure them appropriately.

In addition, condition monitoring can create predictive maintenance plans in conjunction with the simulation models of the digital twins. Customers can also use digital twins to develop and test later changes, optimizations or reconfigurations on the machine in advance on the virtual model and thus implement them more quickly.

Festo has brought the digital twins of its electrical and pneumatic automation products together with other component suppliers into an application where mechanical and plant engineers can experience the advantages of the digital twins live in the engineering tools from Siemens.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.