Additive welding by Cloos Motion Weld

By OEM Update Editorial February 15, 2023 4:43 pm IST

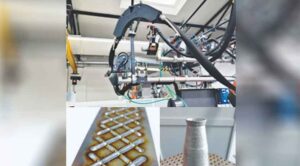

WAAM-Wire arc additive Manufacturing has been facilitated by the development of energy-reduced digitally controlled short arc processes.

“Wire arc additive manufacturing (WAAM)” has now been recognised as a relatively rapid, cost-effective alternative for generating metal components. High deposition rates and lower investment and operating costs compared with powder-based additive manufacturing processes are of particular interest for the production of large volume Components. The use of WAAM has been facilitated by the development of energy-reduced digitally controlled short arc processes and the simplified use of industrial robots for torch movement. Additive manufacturing often means generating of complete components by adding layer by layer.

It is a controlled short arc with reversing wire drive unit. MoTion vari weld also provide additional heat into the process by using a hybrid welding process between short circuits. It is a combination of a classic Control weld process in the short arc range and a mechanical system which draws the wire back and forward at a high frequency. Thus short circuits can be interrupted cleaner and with less energy than in the case of short arcs without reversible wire electrode. Due to the low heat input into the workpiece and the minimised spatter formation at high welding speeds the stable process is particularly suitable for thin plate applications.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.