Hexagon and ESAB will assist firms in streamlining robotic welding procedures

By OEM Update Editorial July 14, 2022 3:19 pm IST

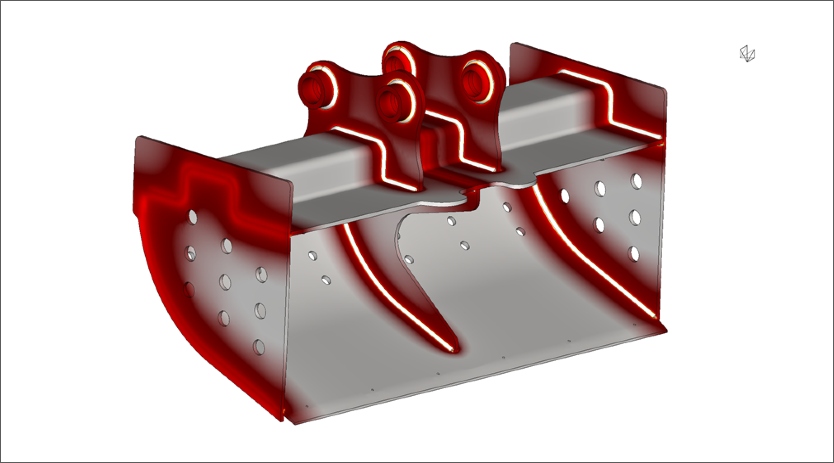

Hexagon’s powerful simulation software with ESAB’s InduSuite solutions to help fabricators perform more efficient and successful welding operations.

Hexagon’s Manufacturing Intelligence division has signed a partnership agreement with ESAB, a global fabrication technology leader, to create a streamlined welding solution combining Hexagon’s powerful simulation software with ESAB’s InduSuite solutions to help fabricators perform more efficient and successful welding operations. Hexagon’s simulation intelligence, embedded within ESAB’s software and automation portfolio, will ensure that users have the tools required to consistently manufacture high-quality products without costly trial and error.

Producing successful welds can be challenging without the benefit of many years’ shop-floor experience and, even with an extensive welding experience, can incur high costs from waste and time. The need to increase process efficiency for the production of welded products in industries such as automotive, aerospace and capital-intensive machinery has increased automation in recent years, but manufacturers now stand to benefit from additional gains by automating elements of design for manufacturing, and ensuring consistent and reliable welding processes with simulation.

“ESAB’s partnership with Hexagon will increase manufacturers’ confidence in their welding expertise,” said Jonas Glimden, VP Digital Solutions and Robotics. “Manufacturers have had the machinery to perform welds as efficiently as possible, and now we can offer our customers a higher level of built-in knowledge with our joint software solutions to help them make better decisions across their fabrication workflow.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.