Hexagon announces Nexus, a platform to connect siloed engineering and unlock smart manufacturing innovation

By OEM Update Editorial June 27, 2022 3:27 pm IST

- The platform will connect people, technology, and data across the design, production and manufacturing workflow to streamline information sharing, drive quality and optimise operations.

- It will empower cross-functional teams with the insights to solve unique problems and collaborate instinctively in real time, connecting their existing Hexagon products and third party applications.

- Teams will be able to innovate using its cloud-based technologies, applications, and solutions to accelerate new product development.

Hexagon’s Manufacturing Intelligence division has announced an open platform for smart manufacturing, Nexus, which will revolutionise how technology professionals collaborate and innovate.

Announced at Hexagon’s HxGN LIVE Global 2022 conference in Las Vegas, Nexus will enable real time data sharing between different design, simulation and production applications. It will connect different applications to form workflows, and combine technologies to develop unique solutions to engineering and manufacturing problems, from concept to delivery. It will empower cross-functional teams to leverage fragmented digital data by improving visibility and connectivity, and help them gain unprecedented insight, bring their ideas to life faster, and produce higher quality results.

Nexus is the foundation for Hexagon’s new solution offerings in the smart manufacturing space going forward. Today, it is capable of leveraging Hexagon data sources from across the vast portfolio; connecting hundreds of Hexagon design and engineering, production and metrology software tools and unlocking new insights from metrology devices and connected machines. Additionally, first-in-class cloud-native visualisations and data management solutions such as HxGN Metrology Reporting and MaterialCenter have been built as cloud-native connected applications, and will be connected through Nexus.

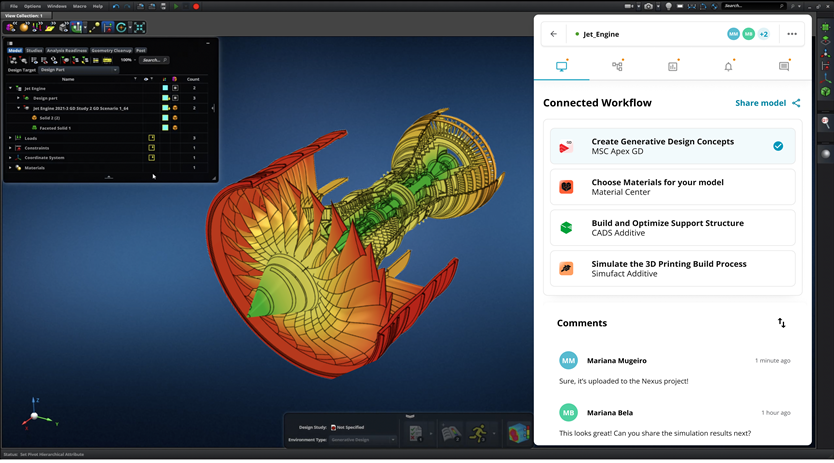

Hexagon is also developing purpose-built solutions through the platform that combine multiple technologies to help users to improve productivity and digitally optimise complex processes and workflows. One example is a “ready-to-go” workflow for 3D printing an optimised reverse-engineered part that could be used, for example, to streamline the repair of grounded aircraft components. This workflow connects data from a 3D laser scan to Hexagon products such as RECreate, MSC Apex Generative Design, MaterialCenter and Simufact Additive, as well as connecting to a third-party market-leading application called CADS Additive to significantly improve productivity and enable rapid collaboration to address production issues.

Parth Joshi, Chief Product and Technology Officer for Hexagon’s Manufacturing Intelligence division, said: “Our customers are managing increased complexity in the market, which is demanding faster innovation than ever. Siloed tools, rigid systems and inaccessible data are increasingly ill-suited to the manufacturing industry’s needs and pressures. Our vision for Nexus is to enhance the products our hundreds of thousands of customers have come to know and love with additional capabilities, powered by the cloud, AI and Machine Learning, real time collaboration and advanced visualisation.“Nexus will allow manufacturers to build more agile and resilient processes so they can respond positively to change and take advantage of new opportunities, create faster pathways to products and develop increasingly autonomous workflows – realising the full potential of smart and sustainable manufacturing.”

To learn more and sign up for updates please visit: https://www.hexagonmi.com/nexus

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.