Cut longer with Kennametal’s KCK20B™ and KCKP10™ indexable milling grad

By OEM Update Editorial May 12, 2022 12:00 pm

New grades offer higher wear resistance and longer tool life, increasing productivity in cast iron and compacted graphite cast iron machining

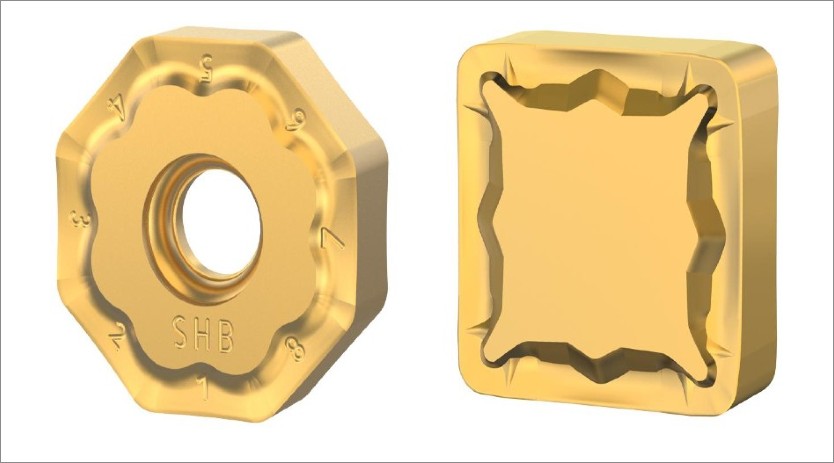

Kennametal has introduced the KCK20B and KCKP10 indexable milling grades for higher wear

resistance and up to 30% longer tool life when machining cast iron and compacted graphite iron

components. Both grades offer higher productivity and consistent, repeatable performance during

roughing, semi-finishing, and finishing operations.

Available for many indexable milling product lines, the new grades come with a golden top layer for

fast, easy wear identification, ensuring maximum tool life for each cutting edge.

“The new grades feature High-Power Impulse Magnetron Sputtering (High-PIMS) technology that

provides a smoother insert surface and optimal layer adhesion for less flank wear – one of the

leading causes of insert failure,” says Gil Getz, Product Manager, Kennametal. He notes that the

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.