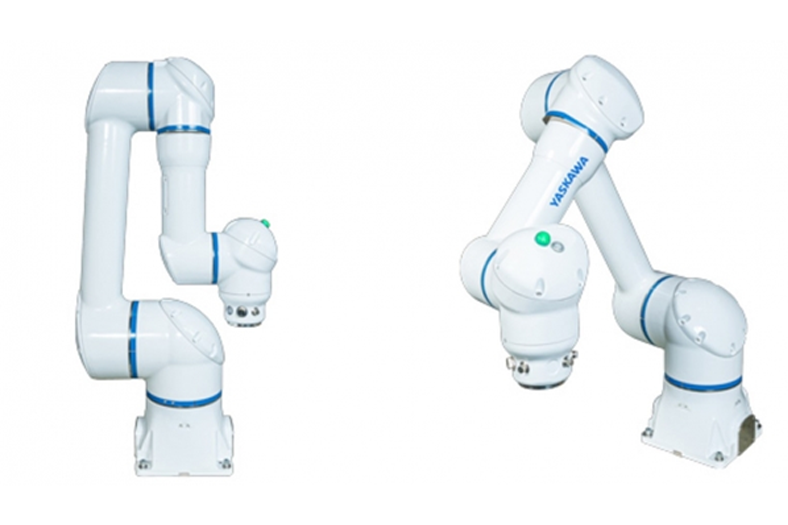

Yaskawa’s Cobot MOTOMAN-HC20SDTP with payload capacity of 20kg equipped with anti-dust and drip-proof functions

By OEM Update Editorial September 3, 2021 6:30 pm IST

Yaskawa Electric Corporation, one of the most advanced & world class manufacturers of Robotics & Drives & Motion Control products, launched a new collaborative robot “MOTOMAN-HC20SDTP” as a new line-up of Human Collaborative Robots. The payload capacity reaches two times with the same length of arm as the 10 kg portable model for wider applications. It is not necessary to surround it with safety fence and the Cobot and people can work together in the same space. The maximum reach length is 1425 mm, which is equivalent to a Yaskawa’s conventional Cobot with maximum load capacity of 10 kg. The new model can also load heavy workpiece, which conventional one could not. In addition, MOTOMAN-HC20SDTP is also equipped with a direct teaching function, so even users who are unfamiliar with robots can easily create operation programs.

Key Features

With a capacity of 20 kg, it can handle large workpieces and multiple workpieces simultaneously

There are a wide range of workpieces in the automotive and parts manufacturing processes, and many processes that handle large workpieces exceed over 10kg. Also, various cases where multiple simultaneous transport of small workpieces occurs to improve work efficiency. By increasing the payload capacity to 20kg, human collaborative robots can be introduced into these processes and expands the range of applications for human collaborative robots.

IEC-standard IP67 realized on all axes with anti-dust and drip proof protection class

All axes are equipped with IP67 anti-dust and drip-proof structure. In addition, acrylic urethane coating is used for the surface coating, and stainless steel is used for the tip flange, making it possible to use it for applications requiring washing with water in consideration of hygiene. Dust does not enter and can be protected against temporary submergence.

Improved ease of use

By placing the connector at the tip of the arm, it is possible to attach the hand tool directly, which also contributes to shortening the setup time. It has also developed a new type of built-in Ethernet cable that is convenient for mounting a camera on the tip of a robot. It can be operated with robot controller YRC1000micro as well as HC10DT anti-dust and drip proof functions.

Safe operation and safe design

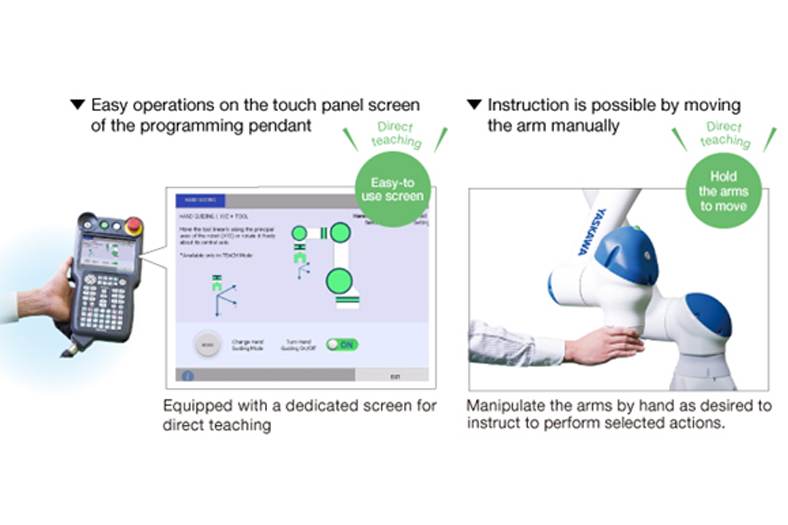

Easy operation even if you are not familiar with robot operation

In addition to conventional teaching methods which use a programming pendant, the robot is equipped with a direct teaching feature where the arm of the robot may be held by hand, operated as desired, and instructed to perform selected actions. As instructions are possible through intuitive. manipulation, the robot will be easy to introduce to customers who are not accustomed to robotic operations and for processes that require frequent instructions.

Main applications

- Transportation and assembly of automotive and machinery related parts

- Input of work into machine tools (machine tending)

- Transportation of food

- Transportation of chemicals or cosmetics and so on.

For more information, visit our website www.yaskawaindia.in or contact YASKAWA India on 24×7 Toll-Free No. 1800 102 3699, Email: marketing@yaskawa.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.