Robots make manufacturing more sustainable!

By OEM Update Editorial August 3, 2021 7:16 pm IST

The write-up outlines how robots are contributing to a more sustainable manufacturing sector highlighting that energy efficiency and waste reduction through robotics.

Ask manufacturers why we are witnessing an increasing uptake of robotics in manufacturing and you can expect to hear arguments about cost savings, worker shortages, and the improved usability of the latest technology. However, the sustainability benefits of robots are also becoming increasingly clear. Here, John Young, APAC sales manager at automation parts supplier EU Automation, outlines how robots are contributing to a more sustainable manufacturing sector.

Enhancing efficiency

The world emits around 50 billion tonnes of greenhouse gases (GHGs) every year. Unsurprisingly, the manufacturing sector is one of the leading producers of GHGs. According to available data, energy use accounts for 73.2 percent of all global emissions and within that figure, ‘energy use in industry’ makes up 24.2 percent.

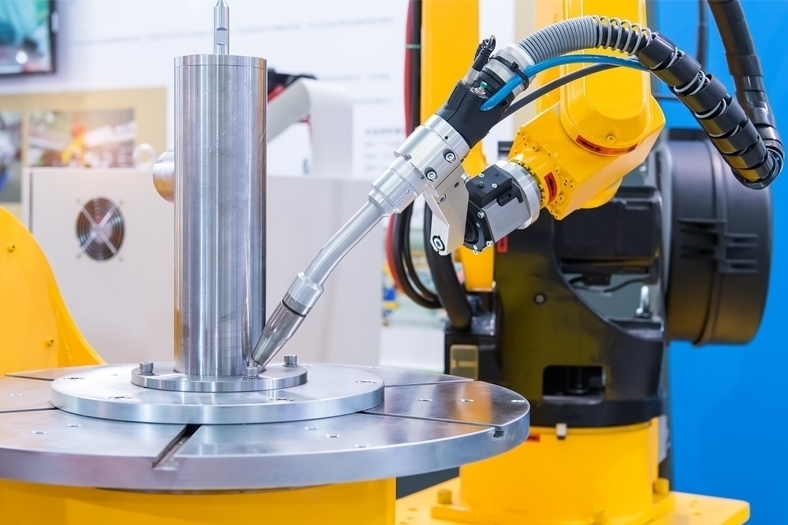

Having robot’s takeover, a production line, or replacing a production line with automated robotic cells, provides a solution to this problem. In comparison to humans, robots do not require as much energy to operate. In fact, greater automation entails a disproportionately large improvement in energy efficiency.

Robots can operate without extensive lighting or heating, ensuring substantial energy savings. Additionally, as robots do not need to commute to work there is also an indirect benefit in reduced transport emissions.

Reduced waste

In addition to enhancing energy efficiency, improvements in robotics and artificial intelligence are enabling robots to provide a helping hand in recycling. One example is the deployment of robots to sort and pick through recyclable objects. This is the case at Apple, where they are used to pick out pieces from discarded iPhones for their repurposing in other products.

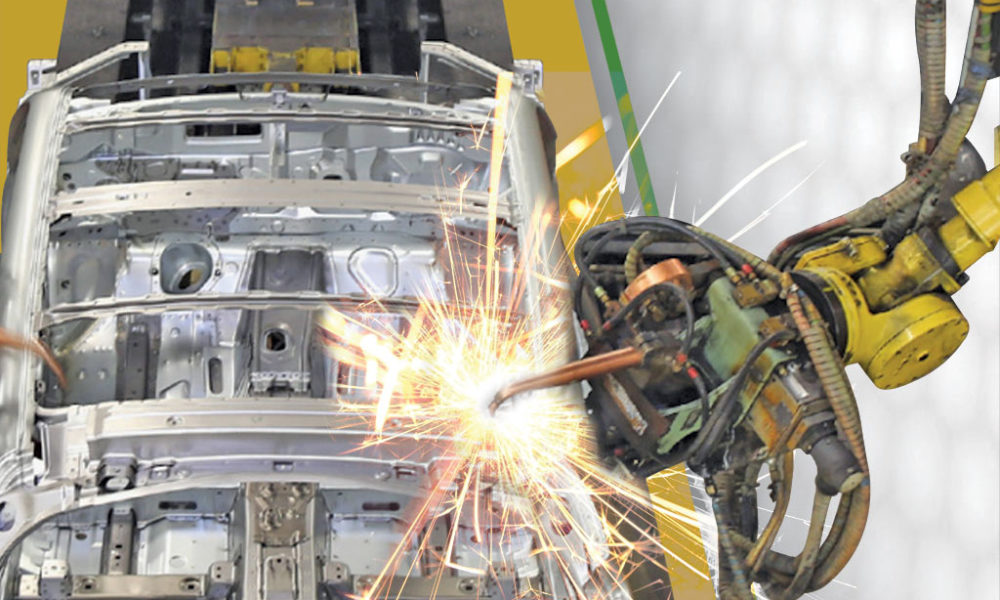

By completing tasks with greater precision than humans, robots can also ensure less material are wasted in manufacturing processes. For example, employing a robot to paint the body parts of a car will guarantee an identical and optimal quantity of paint is used for every car. When manufacturing at scale, the reduction in wasted paint is significant.

Future insightsDifferent types of manufacturing facilities are emerging, enabled by the latest gains in automation technology. For example, while Tesla’s enormous giga factories catch many global headlines, there are plenty of manufacturers looking to benefit from smaller footprints by taking advantage of greater automation.

Robots are becoming more versatile. This means they can be deployed to multiple applications, unlike traditional fixed machines. This reduces the amount of equipment needed and the floor space required. Taken to its logical extreme, this development facilitates the emergence of so-called micro factories.

Greater automation is allowing manufacturers to concentrate more productive capacity into a smaller footprint. A smaller facility uses less energy, but its location closer to the market brings added benefits. As well as savings in outbound logistics, this shift reduces the environmental impact of transporting the final product to market.

Many countries in the APAC region have led the way, both in the design and manufacture, and in the uptake of advanced robotics. While this has led to cost savings and improved productivity, it will also be vital in meeting the goal of a more sustainable manufacturing sector. Whether through greater energy efficiency or reduced waste, robots can play a key part in making manufacturing more sustainable.

EU Automation is a global supplier of automation equipment with customers in 163 countries.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.