G-Code Verification – What are you really checking?

By OEM Update Editorial June 9, 2021 3:12 pm IST

With so much at stake, including the value of the raw or partially completed material, the cutting tools and work holding systems, as well as the structural integrity of the machine tool itself, any NC programming errors will always prove to be costly. Alongside the potential damage to your production capacity there is the prospect of negatively harming the reputation of your business.

While everyone involved with CNC machining understands the importance of checking and verifying the machining process before applying a cutting tool to the raw material, you should consider what are you really checking; and more importantly what are you missing?

With multiple lines of code NC, program errors are a common cause of machine crashes and the two main sources of errors are programmer mistakes (we are only human) and errors introduce by the CAM system’s post-processor.

For programmers and machinists, the task of manually proving out a process can be a slow – checking line by line, block by block to make sure there are no errors in the program. The machine is held up, production time is occupied and the chances of missing an error that could ultimately result in a very costly crash are extremely high. Especially on complex multi axis machining systems.

An alternative to the manual proves-out is to apply CAM simulation and verification software. Many CAM packages will accurately simulate machine motion and are often used to give feedback about the overall machining process. However, despite advances made within the CAM systems they are still limited when compared to independent third-party simulation systems, such as VERICUT.

Limitations of CAM verification

CAM systems offer varying levels of verification based on CL data, that has been post-processed into machine specific G-Code. In reality, this means the CAM system is simulating something different to what the machine will actually run. This is, of course, one of the main hurdles for CAM simulation and verification.

Any simulation that runs on CL data cannot be fully trusted. It is not running the exact same thing that the actual machine is running so there will be differences – in essence it is guessing and projecting what the machine will do as opposed to representing what it will actually do.

In addition, getting true parameters from the machine such as rotary behaviour, shortest distance and so on, is problematic. While machine reference locations such as ‘going home’, where is ‘home’, how does it get there, as well as tool change locations including where does it need to go and how does it get there, are another major limitation of internal CAM verification systems.

The post-processor itself can also introduce errors that could damage the part or the machine. Most CAM verification will use component software for machine simulation, an outsourced generically integrated third party plugin to the software and it is mainly just for material removal and not actually simulating the actual machine motion.

There are some verification systems out there that state “we’re simulating the actual G-Code”. What they are actually doing is posting it and simulating it at the same time and they are projecting what their post is supposed to be doing. So, how can you trust a post-processor driven simulation? Who checks the validity of the post-processor?

Independent G-Code verification is the only wayIndependent G-Code verification software, such as VERICUT, verifies post-processed G-Code instead of the CL data. This is the exact same G-Code that runs within the NC system of the machine, so the software is able to carry out a comprehensive machine simulation based on the same data that will operate the machine.

Unlike CAM verification, the machine features, components, fixtures and stock are identical to the physical process and it offers accurate feature-rich models, cylinders, cones and so on. Multiple setups are supported as cut stock is automatically transferred between set-ups in the proper orientation. All cut history is maintained from the first set-up to the second set-up and so on. This allows the user to quickly and easily identify problems, with a click of the mouse.

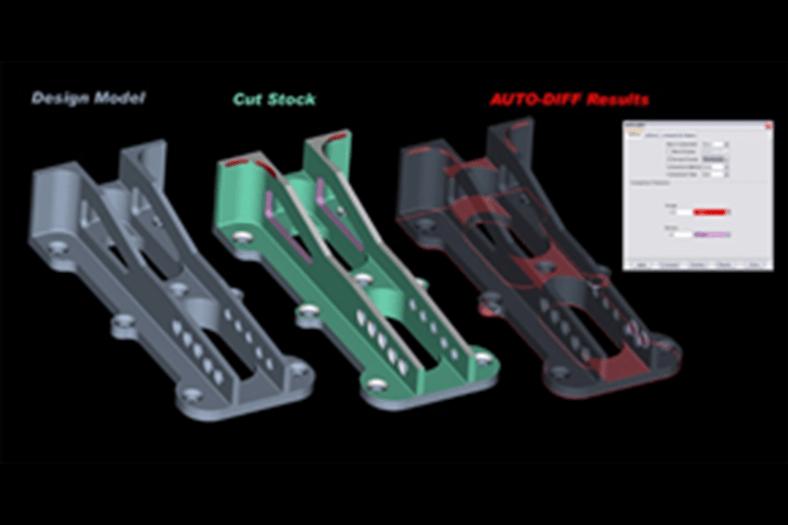

Measurement and inspection tools allow the user to check and verify the dimensional accuracy of cut models, something most CAM verification systems cannot do. With in-process measuring, known as X-Caliper in VERICUT, cut stock can be measured at any time, including hole depths, volume removal, model thickness, air distance, diameter/radius, centre of gravity and many more. While the AUTO-DIFF feature compares the CAD design model to the simulation to detect differences, gouges or excess material. This way the user can be certain that the final component precisely reflects the design intent.

VERICUT not only simulates and verifies the accuracy of the machining process, it can also optimise the G-Code by adjusting the feed rates for each cut to make the process safer, faster and more efficient. It drastically reduces cycle times so inadvertently you get faster turnaround, less out-sourcing, reduced tool breakage and longer tool life.

The advantages of using independent G-Code verification

Simulating, verifying and optimising the machining process with independent G-Code verification software, such as VERICUT, eliminates any fear of a new NC program and reduces setup time. The checking is done during production planning before any real machining starts. So, you never waste valuable machining time and you will be confident that the process will deliver accurate parts with no machine crashes, while adjusting feed rates to optimise machining time and prevent broken cutters.

Given the advantages of using an independent verification system you have to ask ‘is your internal CAM simulation good enough?’

For more information, visit the CGTech website at www.cgtech.co.uk,

Contact number: +44 (0)1273 773538

Email: info.uk@cgtech.com.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.