ABB robots increase automation in the solar industry

By OEM Update Editorial May 20, 2021 4:49 pm IST

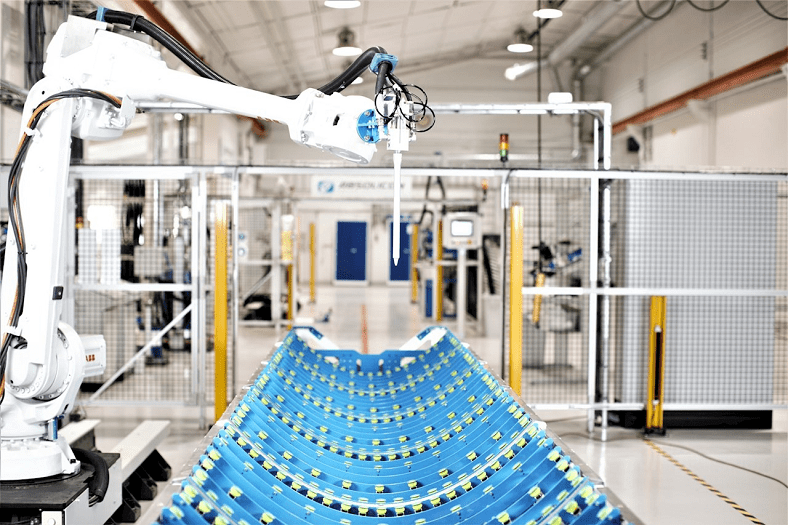

Absolicon’s robotic production line now uses two ABB robots to produce a solar collector panel every six minutes, compared with up to only three units produced a day using previous manual production methods.

To achieve the transformation to a sustainable society and preserve resources, for precise, high efficiency and cost-effective production of solar collector panels, Absolicon and ABB have developed the world’s only complete solution for the mass production of concentrated solar collectors, in Absolicon’s factory in Härnösand, Sweden.

The degree of automation has increased production drastically. Absolicon’s robotic production line now uses two ABB robots to produce a solar collector panel every six minutes, compared with up to only three units produced a day using previous manual production methods.

“Developing an automated production process enables our global business case by radically reducing the price of our solar collectors while manufacturing them consistently to a very high quality. The productivity offered by ABB’s robots means we can make solar energy compete on price with conventional industrial heating for the first time,” said Joakim Byström, CEO of Absolicon. “Our new automated production line can produce a complete solar collector every six minutes, so while competitors rely on a manually intensive manufacturing process, we can now do it with five people, two robots and a fraction of the components.”

Absolicon has been developing sustainable solar technology for 20 years and produces parabolic solar collectors that are the most efficient in their class, generating heat and steam up to 160 degrees for industrial companies and district heating networks.

www.abb.comCookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.