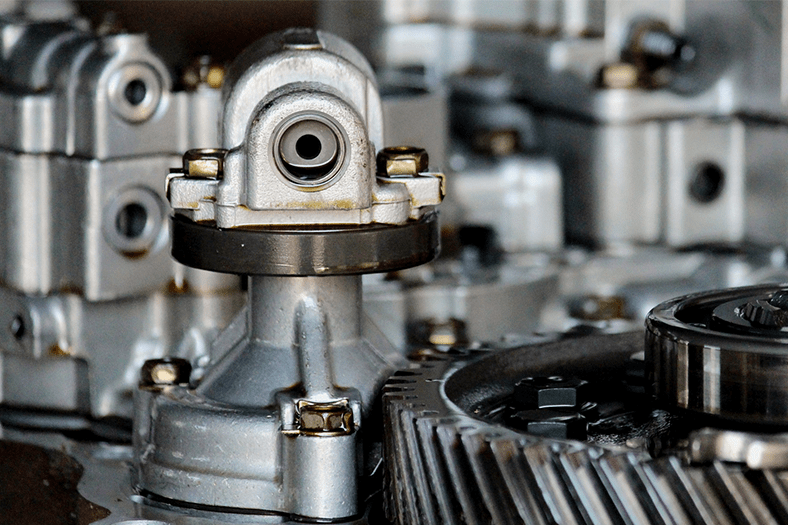

Improving cost efficiency in gears, motors and transmission

By OEM Update Editorial May 7, 2021 4:13 pm

Embedding automation in gears, motors and transmission, have enhanced the performance, and has improved the cost-efficiency whist maintaining the quality.

Gears and motors are a pretty well-established technology; but recently, we see a renewed interest in gear-motors, following a trend in integrated systems in general, because rising energy costs are driving the demand for improved process efficiencies. This presents an opening for gear motors that can be used in a variety of applications and represents a tremendous opportunity for global energy savings.

Performance of gear, motor and transmission in various market

A gear-motor delivers high torque at low horsepower or low speed. The speed specifications for these motors are normal speed and stall-speed torque. These motors use gears, typically assembled as a gearbox, to reduce speed, which makes more torque available. Gear-motors are most often used in applications that need a lot of force to move heavy objects. Asia-Pacific is estimated to be the largest market for gear-motors, with China expected to lead the market in terms of growth rate till 2021. The increasing investments in renewable energy, especially wind power generation, and industrialisation in countries such as China, Japan, and India have propelled the growth of the market in the region. The gear-motor industry is expanding in developing countries, owing to rising industrialisation and infrastructural development activities.

Increasing wind power installations and the low cost and compact nature of the equipment are major factors driving the global gear-motor market. The gear, motor and transmission segments which are moving towards mobility will stay stable for the foreseeable future. However, with respect to the automotive and machine tool markets, they could see a reverse effect due to the reduction in number of engine units because of the rise of battery-driven units. “This will impact the associated industries as well, for instance, the tooling required for the connecting rods and piston. The volume of such tooling required will go down,” explained Karthik Shankaran, Chief Innovation Officer, Detroit Engineered Products. The growth or slowdown of the construction industry heavily depends on the infrastructure spending from the government.

New technological innovations in light of ‘National Technology Day’

Market projectionDiscussing how the segments will perform in the next two years, Shankaran concludes, “It is going to be a challenging time ahead. Automotive volumes as a trend are going down due to connected mobility and shared mobility. Automotive volumes will most likely continue to roughly remain the same, in about the 10 percent range. The automotive industry will have to focus heavily on aftermarket sales and services to remain relevant.” Industries will have to balance their portfolio and work on a diverse product range to cater to a larger customer base in order to stay sustainably profitable in the coming years.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.