Increasing machine’s flexibility with injection moulding

By OEM Update Editorial May 2, 2021 6:06 pm IST

The major drawback of injection moulding is that the up-front costs are usually extremely high due to its design, testing, tooling and machine needs.

Injection moulding is a widely used process in manufacturing of any plastic product. It is one of the important aspects of the plastics industry and has been integral part towards the growth of global manufacturing businesses. The process of injection moulding is fast and is meant to manufacture large amounts of the same product in a short span of time. The injection moulding process has become one of the most popular modern manufacturing techniques. There are versatile applications of injection moulding processes and can produce a myriad of parts for various products.

The moulding processing of products is actively used in every modern manufacturing industry where plastic products are required including aviation, automobile, aerospace, electronics, medical equipment, consumer goods etc. The basic manufacturing process of injection moulding is quite simple. A thermoplastic polymer or plastic is heated above its melting point in an injection moulding machine. This converts the plastic to a molten fluid, which is then injected in a mould cavity and subjected to a high pressure. Finally, it is cooled, solidified and removed from the mould. This process gives the product a solid form and predefined shape.

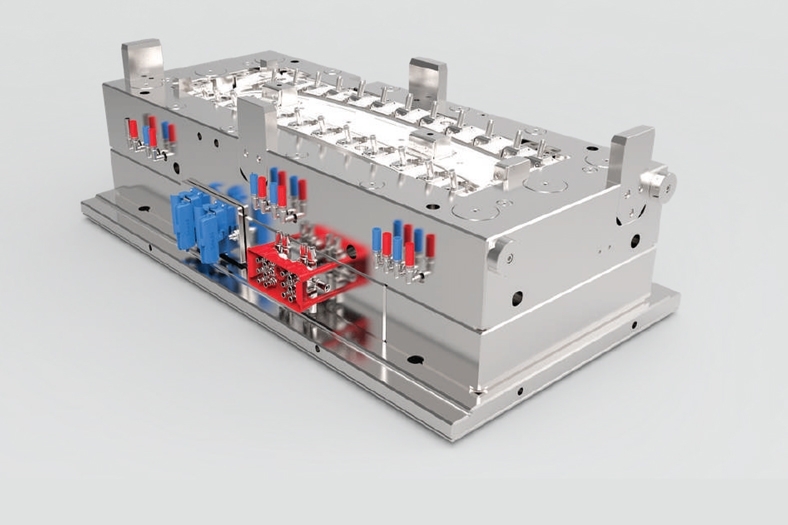

Many of our day-to-day items around us have been manufactured using this process—from the lids of our Tupperware containers to plastic parts of our electrical appliance to our toys. The process is carried out in a moulding machine, commonly known as an injection press. This machine has three basic parts: the injection unit, the mould and the clamping system. There is also an elaborate control system that automatically administers the moulding functions. Injection moulding machines come in various sizes and capacities from 50 tons of clamping force to more than 6000. There are also different kinds of injection moulding machines available in the market and are categorised based on the driving system used–hydraulic, mechanical, and electric and hybrid machines.

The machines are available with a choice in the size of injection unit, as smaller injection units provide better accuracy for producing relatively smaller parts. Furthermore, there are other customisable parts of the machine as per the need of the manufacturer. There are many unique advantages of injection moulding, which has made it an important process in the modern manufacturing industry. This and detail-oriented parts while maintaining highest quality and precise size. Once a well-designed and errorless mould has been created, the injection moulding process is fairly repeatable and aids bulk production.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.