Simplifying pharma F&B processes with automation

By OEM Update Editorial March 3, 2021 5:44 pm IST

Industry experts discuss the management of Pharma and F&B sector amidst increase of demand due to Covid-19

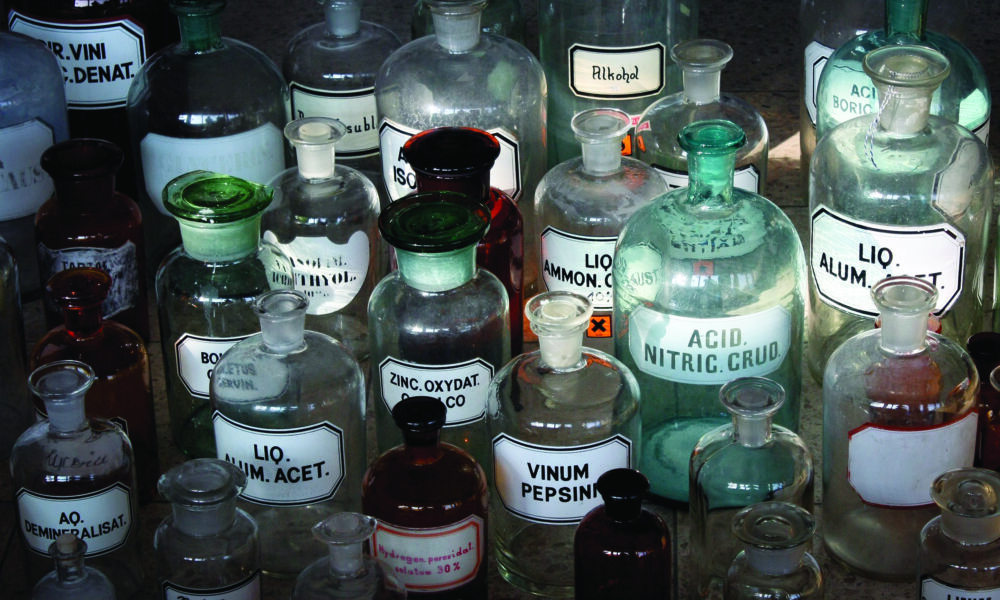

Packaging and printing norms and technologies have undergone a drastic change in recent years, particularly for the pharma and F&B sectors. Historically, machine and human safety has been a second priority in Indian manufacturing. With globalisation, in recent years, we are seeing a positive change with a higher impetus on safety by machine builders and factories. Pharma and F&B are both highly regulated, and product and food safety is of utmost importance. It is essential for machines and factories to comply with these stringent regulations with usage of hygienic systems for automation. One of the key challenges faced by the packaging and printing companies is to keep pace with the ever-changing consumption pattern of the aspirational Indian consumers. They need to keep experimenting and come up with products scoring high on shelf life, variety, convenience, and health.

Growth opportunities for the pharmaceutical sector

The budget has brought a much-needed fillip for pharmaceutical and healthcare industry, with a view of building a resilient health system. Moreover, additional measures towards better sanitation and boosting nutrition are expected to improve well-being of citizens. Shyam Padwal, Pharma Industry Expert, B&R Industrial Automation, Says, “Pharmaceutical and healthcare have been in focus for a long time but with the recent pandemic there has been an added impetus towards its efficient functioning. With largest number of US-FDA approved pharmaceutical plants outside the US, India can be rightly called the pharmacy of the world.” Where as Sameer Gandhi, MD, OMRON Automation, India says, “While much will depend upon the detailed allocation of these funds, we expect this to provide a big boost to the pharmaceutical sector leading to an increase in production of medicines and a consequent positive impact on the packaging industry.” Coupled with spends on healthcare, rise of e-pharmacy and loss exclusivity without doubt has put pharmaceutical sector in India on the fast track for growth. The union budget is expected to provide access to ‘healthcare for all’ in our country and will simultaneously fuel jobs boosting economy.

Automation, 3D printing and robotics helped the Pharma / F&B sector to maintain quality in their processes and their deliverables during the pandemic

Contact free, contamination free and hygienic products have been a consumer focus in the recent pandemic. Even order ins or grocery through online delivery apps were promoting contact less deliveries. On the manufacturing front, automation and robotics were instrumental in keeping productions going ensuring supply matched growing demands hygienically. With RFIDs, track and trace, audit trails, robotics packaging and lines complying with US FDA 21 CFR part 11, facilities have been able to function with extra care ensuring higher product quality and reduced risks of contamination. Padwal says, “Secure remote access, diagnostics and maintenance practices such as predictive maintenance have helped these facilities to keep their production and maintenance schedules without facing unplanned downtimes and avoid wastage and losses. On the R&D front, 3D printing solution possibilities have paved the way for shorter R&D times, reduced losses and wastage.” This is just the tip of the iceberg on the enormous possibilities automation and robotics has brought in for the pharma and F&B sector. These technologies have not only made production easier and comfortable in these tough times but also have helped facilities to enhance quality and optimise processes amongst many other benefits.

The safety norms being followed in Pharma / F&B sector

Apart from product safety, hygiene and quality, process and machine safety have been very important for many years. The European machinery directives had the intent on ensuring common safety level making movement of machinery and products across Europe. Thus, machine builders supplying machines and lines from across the globe need to adhere to these common safety guidelines. Padwal says, “In addition, compliance with US FDA, audit trails and ease of track and trace have all been of prime importance for pharma and F&B sectors. B&R overcomes the aspect of security and compliant easily in a single system with PharmaEdge, which reduces costs at the same time enhances security. It is an integrated, out-of-the-box, optimized offering for pharma industry to meet increasing demand of FDA compliance. It helps to achieve cyber-security and advanced functionality of elaborate reporting, analytics and business intelligence. PharmaEdge offers all benefits of SCADA and a powerful control system in one device.” With possibilities to add energy monitoring, condition based predictive maintenance and MES / ERP connectivity, it enables implementation of smart and futuristic machines. To which Gandhi adds, “The solutions came to the rescue of the makers by making high-mix-low-volume (HMLV) operations possible. Manufactures grappling with constantly changing routings, quick and frequent changeovers as well as a lack of consistency in the wake of unavailability of manpower and social distancing norms, found a solace in cobots as their companion. Cobots make the programming easy owing to their built-in vision. Moreover, same cobot can be used for different cells, on-the-fly, which adds on to the convenience.” Along with cobots, AMR -another highly versatile robot- saw an increase in deployment in the ‘new normal’ owing to their ability to move material while working alongside people on a busy shopfloor.

Latest automated technologies being implemented in pharma sector to precision and ease in processes

————————————–Adaptive manufacturing has caught the attention of pharmaceutical, F&B and medical device assembly professionals and organizations.

Shyam Padwal, Pharma Industry Expert, B&R Industrial Automation

————————————–

Cobots make the programming easy owing to their built-in vision.

Sameer Gandhi, MD, OMRON Automation, India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.