Increased investments in digitisation for flexibility and productivity

By OEM Update Editorial January 22, 2021 10:00 am IST

We are beginning to see machines with robotics, cell automation and more for higher output but in the areas of continuous productivity improvement, predictability and flexibility.

Productivity is accurately defined as a ratio of output volume in standardised units to input volume in the same units; and it’s simply a measure of how efficiently diverse production inputs are being used to produce a given level of output. However, when we talk of workplace productivity, we are referring to how much is accomplished in a specific work environment over a specified period. We expect and want workplace productivity to keep getting better and be maximised (optimised) in matured businesses. However, the market for mature products and services keeps getting more complex and challenging; throw into this black swan event like COVID-19 and it becomes something else.

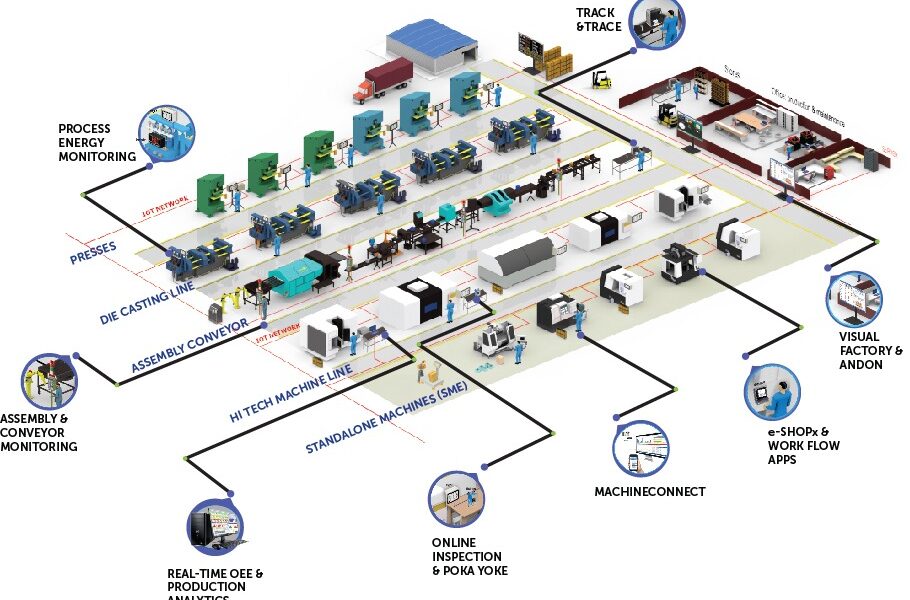

The attempt being made here is not about how we deal with extraordinary situations but to look at a practical approach towards productivity with automation, connectedness, data, information and accomplishment in a wholesome manner that could be starting from the centre and branching out, or alternately starting at pain points and merging into the central system. Wholesome performance accomplishment is not one-dimensional; it improves the productivity along with quality, flexibility, and transparency that give an agile work environment which empower its people and its customers.

If we take the metal cutting component manufacturing business, machining is the core activity, cost and the technicalities of machining metals matter, but from the workplace productivity perspective there are hundreds of issues that impacts it and which are usually clouded from sight but addressed, it gives huge gains in a cost effective manner. The requirement now is how to look in deeply, relevant data, a process to make this data meaningfully and an index to show direction. This kind of meaningful connectedness is strictly not productivity but is a true productivity amplifier. So how we go about this is not usually a one size that fits all approach but understanding the unique requirements and adapting universal standards to get the best of both worlds.

(This article was authored by: T K Ramesh, CEO, Ace Micromatic Group)Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.