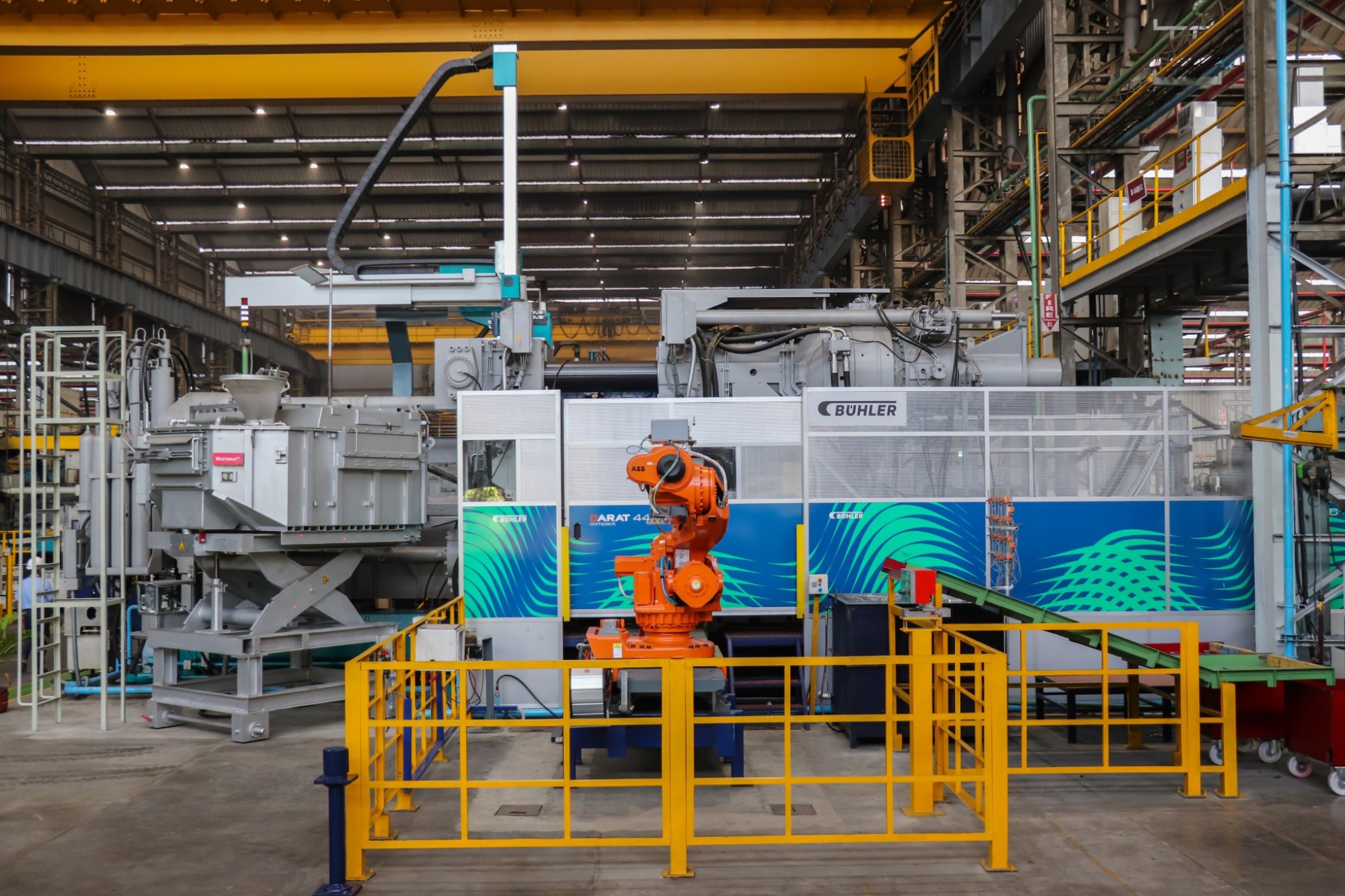

ABB: Condition-based maintenance service for fleet and individual robot assessments

By OEM Update Editorial January 22, 2021 9:48 am IST

ABB’s new Condition-Based Maintenance (CBM) service enables robot users to create a preventive maintenance schedule for individual or robot fleets based on real-time operational data, to optimize productivity and minimise downtime.

CBM uses real-time data on robot operations to help identify any potential issues that could affect performance, including duty, speed, acceleration, and gearbox wear. These variables are compared against other robots in ABB’s worldwide robot database to calculate the likelihood and timeframe of a potential fault or failure.

Aimed at customers with large fleets of robots, ABB’s CBM tool can advise whether remedial action is required, involving either repair or replacement of affected parts. By identifying which parts are likely to fail and when, spare parts can be purchased and prepared without having to hold them in stock, helping users to plan their budgets and ensure that resources are available to carry out the work when required.

Previously, it was difficult for users to determine whether key parts such as gearboxes were becoming worn or in need of replacement. This meant that problems were either undiagnosed until a failure, or parts were purchased unnecessarily or were un available when needed, disrupting production while the robot is offline.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.