The Future of Work

By OEM Update Editorial August 13, 2020 6:17 pm IST

This article explains how Cobots are going to transform the way we work in the future

The outbreak of COVID-19 has impacted industries across the globe. While the lockdowns might be lifting, the world will still have to get used to practices like social distancing, wearing masks, etc. In such times, the only way to get back to the ‘new normal’ is through technology.

The implementation of technologies like Robotics, AI, and Cloud computing in manufacturing has increased and continues to be growing year by year. This has motivated almost every industrial sector to move towards automated operations at a faster pace.

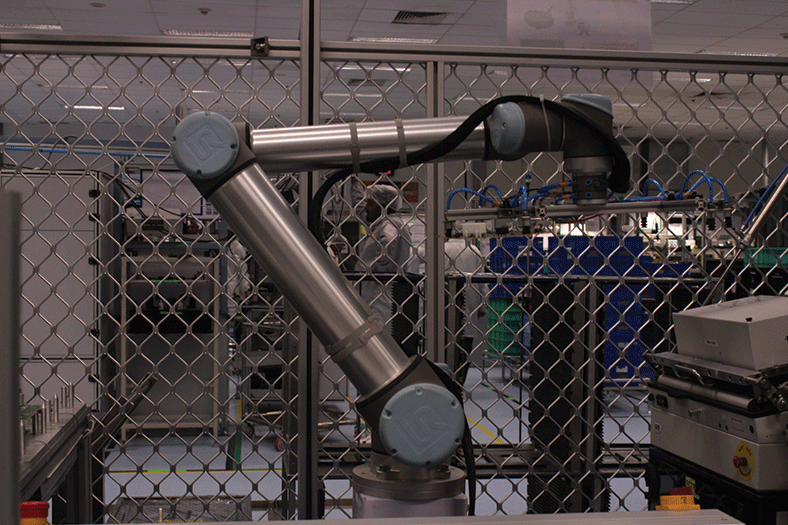

One such way of technological advancement is Cobots. As the name suggests, Collaborative Robots or Cobots, are designed to work alongside and together with humans. These are complex machines that conduct complicated mechanical operations. Unlike traditional robots, which are autonomous in their operations, Cobots are designed to share the workspace with humans.

Cobots are generally employed to perform tasks that can result in being repetitive, dangerous, or not ergonomic, such as assembly, carrying heavy components, and quality inspection.

Cobots Impacting for Good

The Cobot market is estimated to be worth a staggering $3.1 billion by the end of 2020. Cobots have already been deployed across industries like automotive, food, healthcare, pharma, and manufacturing. Cobots can help enterprises to thrive and survive the many challenges they are currently facing. They have various advantages.

Process optimisation: The main objective of employing Cobots in enterprises is the increase in productivity. This can be achieved through the minimisation of errors and higher accuracy.

Safety: Cobots’ sensors can detect the presence of humans or other obstacles and stop or adjust their operations accordingly to avoid incidents or accidents.

Reduced Downtime: Cobots could also help reduce the amount of downtime in a company – a critical factor in current times when we have limited time to work.

Reduction in costs: Cobots generally cost just a fraction of traditional robots, making them advantageous even for small and medium enterprises (SMEs). Once installed, Cobots ensure a more functional and flexible workplace, but also enhanced productivity, granting thus a higher return on investments (ROI). Additionally, many robotics manufacturers offer service policies to make Cobots more accessible.Straightforwardness to program: Traditional robots demand large amounts of knowledge to program their operations. On the contrary, Cobots are easy to program thanks to the use of mobile applications and software.

Rapid setup: Cobots are user-friendly and easily programmed through software and programs, making them operative in less than an hour.

Attracting Talent with Cobots

India has more than 50 percent of its population below the age of 25 and more than 65 percent below the age of 35. The millennials across the world have always been famous in looking for a work environment wherein they get access to the latest technologies. As the industry moves towards Industry 4.0 and involves more automation technologies, more talent will get excited to work in the space. This would also help relieve a strained workforce from manual or challenging work and would allow the human workers to undertake the more creative aspect of their roles. This time can be used to focus on new ideas, innovation, and add higher-value work for the business. This, in turn, will help boost the revenues.

Considerations

For industries that want to produce premium products, providing an optimal working environment for employees to boost output, revenue, and productivity simultaneously, Cobots would be the answer. But to effectively embrace and integrate Cobots into the workforce, appropriate preparations are essential. Manufacturers must ensure they have an up-to-date Information Technology (IT) infrastructure in place to support this new technology. In addition to this, solutions such as modern enterprise resource planning software will be crucial to coordinating Cobots workflows and enabling useful data sharing between machines and humans across multiple digital platforms.

The Future of Cobots

As we move towards connected and AI-enabled smart factories, the Cobots will become even intuitive. In the future, we will witness Cobots learning from their human counterparts. They will see humans performing the task, fill further, and improve their actions accordingly.

Cobots complement humans in their day-to-day tasks. In the connected future arena, they will play a significant role in improving productivity, quality, and efficiency. Cobots, along with other Industry 4.0 initiatives, will also help companies in attracting more talent. Cobots are meant to transform the way we operate for good.

Authored by:

Sirisha, Head Industrial Engineering &

New Product Launch,

Continental Automotive India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.